Preventing expensive unscheduled shutdowns by knowing the state of electrical supply systems

June 2000

Analytical Instrumentation & Environmental Monitoring

Anglo Allied Engineering

The sudden loss of electrical power, even in a small section of a modern plant, can result in the unscheduled shutting down of the whole plant which may prove to be very costly. Obviously, a good 'feel' for the state of the electrical wires and insulation in the plant would be of great help when planning scheduled maintenance and equipment overhauls.

In distributed IT TN and TT systems, insulation fault location can also be costly in terms of time and money. The Bender on-line insulation fault and residual current location system provides an automatic solution to these problems.

Time and money are saved by being able to monitor residual currents and verify insulation integrity while the plant is still running. The system will indicate the exact location of the fault, saving time looking for it. The resultant early preventative maintenance, without having to shut down the plant, makes it a cost-effective approach.

The system is modular and flexible, able to monitor the electrical supply system in any plant. Its flexibility permits easy retrofitting and extension, with up to 360 branches capable of being monitored by one system.

Its universal application is implemented through three system types. The EDS system is for use with all AC/DC IT systems, the RCMS system is for all AC, TN and TT systems and there are portable systems for working with small power systems and subcircuits. EDS devices comply with IEC/EN61557 \9 (draft).

Insulation fault

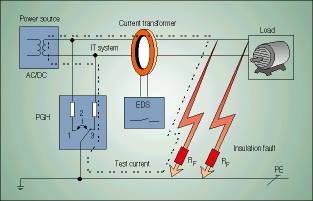

When an insulation fault occurs in IT systems, it will be detected and indicated by the A-Isometer insulation monitoring device. The test device generates a test signal for a defined period. This test signal will propagate via any insulation fault locations, and be able to be detected at any of the current measuring transformers within the insulation fault path.

Residual current location

All the conductors for a given circuit are fed through the core of a current transformer. In normal operation, the sum of all the currents will be zero. In a fault condition, there will be an imbalance in the total. This imbalance will be detected by the current transformer and the result will be evaluated by the RCMS470's electronics.

A maximum of 12 current transformers (ie 12 circuits) may be monitored by one RCMS470-12 evaluator, any faulty circuits are indicated by an LED. All the RCMS units work in parallel to minimise system evaluation.

The combination of an RCMS and PRC provides a central control and display of the measuring results and pre/main alarm warning set-up (10 mA to 10 A) for each circuit. The use of current transformers allows the RCMS system to be independent of both the load current and the voltages used in the installation.

Central control unit

The PRC470 is the central control unit for the system. All monitoring parameters and important operating states are displayed in a test window, providing a compete overview of the entire installation. Communication interconnection between controller and the evaluators is made by means of a cost saving two-wire interface which is easily extended.

Further reading:

Precision in every drop, powered by ICP technology

Wearcheck

Analytical Instrumentation & Environmental Monitoring

Elemental profiling using Inductively Coupled Plasma – Optical Emission spectroscopy provides useful information on the chemical composition of lubricants.

Read more...

A trusted oxygen analyser back in action

Elemental Analytics

Analytical Instrumentation & Environmental Monitoring

After a period of discontinuation, Servomex’s Oxy 1810 oxygen analyser has officially returned.

Read more...

Multi-channel pH and conductivity controller for the water sector

Senseca

Analytical Instrumentation & Environmental Monitoring

The measurement of pH and conductivity plays an integral role in water systems. Senseca South Africa has introduced a multi-channel controller that allows the connection of up to five digital sensors and a frequency-emitting flow sensor.

Read more...

DEKRA Industrial sets new standards for asset integrity in local petrochemical sector

Analytical Instrumentation & Environmental Monitoring

DEKRA Industrial South Africa has strengthened its position as a leader in hydrogen-induced cracking inspections through a strategic combination of advanced non-destructive testing techniques, investment in state-of-the-art inspection equipment and global technical collaboration.

Read more...

ABB leads in emissions monitoring with industry-first data acquisition system proficiency test

ABB South Africa

Analytical Instrumentation & Environmental Monitoring

ABB is the first company to offer a complete package of continuous gas analysis and DAHS systems fully compliant with international standards.

Read more...

Ensuring clean and safe water

Endress+Hauser South Africa

Editor's Choice Analytical Instrumentation & Environmental Monitoring

Endress+Hauser’s comprehensive range of disinfection sensors is designed to monitor and control disinfectant levels in water treatment processes.

Read more...

High-precision measurement of insulating gases

WIKA Instruments

Analytical Instrumentation & Environmental Monitoring

WIKA has launched the next generation of its GA11 gas analyser. It enables switchgear operators, manufacturers and maintenance companies to record the quality of SF6 gas and alternative insulating gases.

Read more...

Say goodbye to missed contamination with real-time colour monitoring

Analytical Instrumentation & Environmental Monitoring

Applied Analytics offers seamless and rapid colour monitoring in processes with an industry-proven analyser that quickly and accurately monitors colour in your sample stream for impurities and inconsistencies.

Read more...

Metrology laboratory is the heart of data-driven production consistency

Analytical Instrumentation & Environmental Monitoring

Pressing and welding have been at the core of Tier 1 automotive supplier, Malben Engineering for 50 years; but it is the company’s investment in its state-of-the-art metrology laboratory which has set it apart.

Read more...

Unlocking precision: The future of inline concentration measurement

Analytical Instrumentation & Environmental Monitoring

[Sponsored] In today’s resource-conscious industrial world, manufacturers are under growing pressure to optimise productivity, ensure consistent product quality and minimise waste. One of the most effective levers for achieving these goals lies in mastering concentration measurement, and Anton Paar is redefining how it is done.

Read more...