The food and beverage industry is under constant pressure to produce consistent, high-quality products while controlling costs and maintaining stringent hygiene standards. Precision sensors and monitoring technologies have become indispensable not only for process efficiency, but also for safeguarding against microbial threats that can compromise both equipment and product quality.

Instek Control specialises in advanced measurement solutions tailored for the food, beverage, pharmaceutical and mining industries. Among the company’s offerings are advanced process sensors from Anderson-Negele, as well as ALVIM biofilm monitoring technology. Together, these contribute to improved efficiency and reduced waste while mitigating contamination risks.

Smart sensors for food andbeverage production

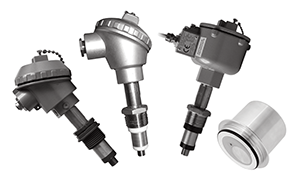

Anderson-Negele is a global company specialising in the development and production of sensors and measuring equipment for hygienic applications in the food, beverage and dairy sectors. The company’s latest generation of turbidity, conductivity and flow meters integrates digital connectivity, modular design and hygienic construction to provide reliable and actionable data in real time to improve efficiency, reduce waste and maintain compliance, all supported locally through the technical expertise and service of Instek Control.

ITM-4 four-beam turbidity meter

For processes where clarity is critical, such as separator automation or filter monitoring, the ITM-4 provides highly accurate measurement at very low turbidities down to 0…5 NTU. Using four-beam sapphire optics with pollution compensation, it delivers stable results without the need for a separate evaluation unit. Operators benefit from precise phase separation and efficient fresh and wastewater monitoring, ensuring both quality and compliance.

ITM-51 modular turbidity sensor

For higher and more variable turbidities at 200…300 000 NTU, the ITM-51 offers flexibility and reliability. Its front-flush sapphire optic design makes it easy to clean and resistant to buildup, while the modular design allows users to configure any system from a cost-effective basic unit to a high-end sensor with full digital connectivity. By enabling accurate phase differentiation in processes like whey cream separation or clean-in-place (CIP) return monitoring, it reduces water and chemical consumption while cutting cleaning cycle times.

ILM-4 conductivity meter

CIP systems are resource intensive, and optimisation can lead to major cost savings. With its rapid 1,2 second response time, the ILM-4 inductive conductivity meter allows switchover between water, cleaning agents and product based on actual measured values, not preset times. This ensures cleaning agents are fully utilised, reduces rinsing water usage and shortens overall cleaning cycles.

FMQ magnetic-inductive flowmeter

For dosing, filling and general flow monitoring, the FMQ offers accuracy down to ±0,5% ±2 mm/s, even at low flow rates. Its hygienic stainless steel design, piggable PFA coating and IO-Link connectivity make it suitable for both aggressive media and strict hygienic environments, including 3-A certified applications.

The hidden hygiene challenge

Microbial contamination is another pressing challenge. Biofilm, the microbial layer that forms on wetted surfaces, is the most critical component of industrial biofouling. Just 20 microns of biofilm in a heat exchanger can reduce thermal efficiency by 30%, as it is up to four times more insulating than calcium carbonate scale. Traditional detection methods such as pressure drop or thermal efficiency loss can only identify mature biofilms and cannot distinguish them from mineral scaling. For food and beverage plants, early detection is critical to ensure effective sanitation and prevent product contamination.

ALVIM biofilm monitoring system

The ALVIM biofilm monitoring system offers innovative, high-tech solutions for the detection and monitoring of biological fouling in industrial plants. It provides real-time monitoring by measuring the electrochemical activity of biofilm. It can detect coverage as low as 1% of surface area, giving operators the chance to act before biofilm becomes resistant and costly to remove.

Unlike generic fouling monitors, ALVIM specifically identifies biofilm, enabling targeted treatment with biocides rather than broad chemical dosing. The system uses standard communication protocols such as RS485 MODBUS, 4–20 mA. It integrates into existing plant networks and allows distributed monitoring across multiple locations.

Applications in food and beverage plants include:

• Automated biocide dosing: Applying only when biofilm is detected, avoiding the overuse of chemicals.

• CIP effectiveness verification: Confirming whether cleaning cycles remove biofilm.

• Legionella risk prevention: Monitoring of biofilm in cooling towers and water circuits where bacterial pathogens thrive.

By shifting from reactive to proactive biofilm management using ALVIM technology, operators can reduce chemical use, lower environmental impact and enhance food safety.

Local expertise through Instek Control

Combining world-class technology with trusted local expertise, Instek Control is more than just a supplier. The company provides engineering know-how, training and service to help its customers in the food and beverage industry seamlessly integrate advanced instrumentation into their existing processes. This ensures that they can achieve precise, reliable monitoring while meeting stringent international standards, and improve efficiency, sustainability and plant safety.

| Tel: | +27 12 998 6326 |

| Email: | [email protected] |

| www: | www.instek.co.za |

| Articles: | More information and articles about Instek Control |

© Technews Publishing (Pty) Ltd | All Rights Reserved