Profiler 'sees' through tank walls

February 2002

Analytical Instrumentation & Environmental Monitoring

A version of the Tracerco Profiler had already proved its accuracy and reliability on-shore in refinery vessels for a combined total of 20 years when the technology was applied to separator measurement and control.

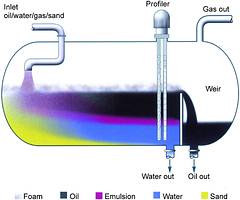

The instrument comprises sealed titanium dip-pipes installed within the separator through a single 6" or 4" flange. A narrow dip-pipe holds a vertical array of low energy radiation emitters. A typical system will have two parallel dip-pipes, each holding a detector of up to 48 Geiger Muller tubes. Combined, they can give a 96-point measuring system with a minimum vertical pitch of 28 mm.

Each emitter transmits radiation through the fluid within the separator to be picked up by the detector. Oil, water, sand, foam and emulsion have different densities, they will attenuate the signal passing through them by different amounts. The density registered by each tube is transmitted to a signal processing unit housed in the dome, above the dip-pipes.

Figure 1

The information is converted into serial data and sent via fibre-optic cable to the plant computer. On the screen the fluid density at each 28 mm channel is depicted in realtime. For the first time ever one can see a complete profile of the distribution of fluids within the separator:

* The interface between water and oil or oil and gas.

* The quality of the separation.

* The extent of foam build up.

* The total liquid position.

* The level of sand build-up.

Figure 2

The BP Forties field

In 1999, the Tracerco Profiler newly installed on a BP production platform in the Forties field detected a considerable build-up of sand within a separator. The operators were unaware of the sand and had attributed poor production rates to reservoir conditions. The thin oil phase made control difficult and good separation hard to achieve without water carry-over.

To remove the sand, the operators began to jet wash the separator. The overall effect was to reduce environmental risk, optimise assets and save on chemicals in the separator.

With the aid of readings from the Profiler, the operators monitored the effectiveness of chemicals added to control foaming and emulsion. Wastage was reduced. The separator was brought under perfect control. With residence time up to target levels, rates of production were optimised. The risk of carry-over was eliminated.

Whilst this was taking effect, a band of emulsion between the oil and water phase and foam on top of the water was observed.

Since installation two years ago, BP has carried out no maintenance on the system. The Tracerco Profiler is suitable for use on floating production facilities.

Tracerco Africa

(011) 706 2592

[email protected]

Further reading:

Precision in every drop, powered by ICP technology

Wearcheck

Analytical Instrumentation & Environmental Monitoring

Elemental profiling using Inductively Coupled Plasma – Optical Emission spectroscopy provides useful information on the chemical composition of lubricants.

Read more...

A trusted oxygen analyser back in action

Elemental Analytics

Analytical Instrumentation & Environmental Monitoring

After a period of discontinuation, Servomex’s Oxy 1810 oxygen analyser has officially returned.

Read more...

Multi-channel pH and conductivity controller for the water sector

Senseca

Analytical Instrumentation & Environmental Monitoring

The measurement of pH and conductivity plays an integral role in water systems. Senseca South Africa has introduced a multi-channel controller that allows the connection of up to five digital sensors and a frequency-emitting flow sensor.

Read more...

DEKRA Industrial sets new standards for asset integrity in local petrochemical sector

Analytical Instrumentation & Environmental Monitoring

DEKRA Industrial South Africa has strengthened its position as a leader in hydrogen-induced cracking inspections through a strategic combination of advanced non-destructive testing techniques, investment in state-of-the-art inspection equipment and global technical collaboration.

Read more...

ABB leads in emissions monitoring with industry-first data acquisition system proficiency test

ABB South Africa

Analytical Instrumentation & Environmental Monitoring

ABB is the first company to offer a complete package of continuous gas analysis and DAHS systems fully compliant with international standards.

Read more...

Ensuring clean and safe water

Endress+Hauser South Africa

Editor's Choice Analytical Instrumentation & Environmental Monitoring

Endress+Hauser’s comprehensive range of disinfection sensors is designed to monitor and control disinfectant levels in water treatment processes.

Read more...

High-precision measurement of insulating gases

WIKA Instruments

Analytical Instrumentation & Environmental Monitoring

WIKA has launched the next generation of its GA11 gas analyser. It enables switchgear operators, manufacturers and maintenance companies to record the quality of SF6 gas and alternative insulating gases.

Read more...

Say goodbye to missed contamination with real-time colour monitoring

Analytical Instrumentation & Environmental Monitoring

Applied Analytics offers seamless and rapid colour monitoring in processes with an industry-proven analyser that quickly and accurately monitors colour in your sample stream for impurities and inconsistencies.

Read more...

Metrology laboratory is the heart of data-driven production consistency

Analytical Instrumentation & Environmental Monitoring

Pressing and welding have been at the core of Tier 1 automotive supplier, Malben Engineering for 50 years; but it is the company’s investment in its state-of-the-art metrology laboratory which has set it apart.

Read more...

Unlocking precision: The future of inline concentration measurement

Analytical Instrumentation & Environmental Monitoring

[Sponsored] In today’s resource-conscious industrial world, manufacturers are under growing pressure to optimise productivity, ensure consistent product quality and minimise waste. One of the most effective levers for achieving these goals lies in mastering concentration measurement, and Anton Paar is redefining how it is done.

Read more...