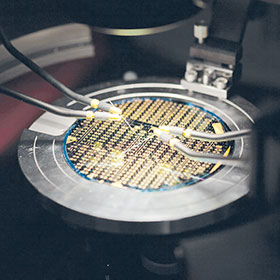

Semiconductor wafers can be transparent or reflective, both of which can be challenging for sensors to detect. Because of this, it is important to use a technology that can detect both types of wafers reliably. Sensor mounting can also be a challenge when detecting wafers in a vacuum chamber. Banner Engineering offers several solutions that can be used to detect both clear and reflective wafers reliably in a vacuum chamber. There are three technologies that can be used to solve this application.

Dual mode laser distance sensor through window glass

The first type of sensor that can be used to detect wafers is a dual mode laser distance sensor mounted through a window glass. Laser sensors with dual mode capability like the Q4X from Banner detect not only changes in distance but also changes in light intensity from a stable background condition. This allows the Q4X to detect challenging targets such as clear and reflective wafers with a high level of accuracy.

A laser distance sensor with dual mode can detect not only when the target is present within a certain distance, but also when it returns a certain amount of light to the receiver. For this to work, a stable reference surface must be taught, and the distance and intensity of the reference surface are recorded and used as a baseline. The presence of a transparent or reflective wafer entering the sensing range of the beam alters the perceived distance and light intensity from the background condition. The Q4X from Banner is also able to detect through a glass window without interference.

Photoelectric sensor through window glass

Another sensor that accurately detects challenging wafers targets is a retro-reflective photoelectric sensor with a coaxial optical design. The QS18 with Clear Object Detection emits and receives light along a single narrow axis. This optimises the detection of transparent wafers by dramatically reducing the risk of false detection from reflected light.

Additionally, because light emitted and received travels on a single narrow beam, these sensors can see through a small aperture, allowing them to be used through a glass window for vacuum chamber applications. Photoelectric sensors with polarising filters will emit and detect light waves of a specific polarisation, ignoring all other light waves. This further reduces the risk of false detection caused by reflected light.

Vacuum chamber-rated fibre

Finally, a fibre optic solution that is rated for use in a vacuum chamber can also be used to detect transparent or reflective wafers. With a fibre optic solution, the fibre amplifier is mounted outside of the vacuum chamber. A special pass-through fitting with a vacuum-rated glass fibre mounted inside brings fibre optic light into the chamber.

The fibre is then positioned so that the light shines towards a vacuum-rated glass reflector, detecting both glass and reflective wafers that pass between the fibre and the reflector.

For more information contact Brandon Topham, RET Automation, +27 (0)11 453 2468, [email protected], www.retautomation.com

| Tel: | +27 11 453 2468 |

| Email: | [email protected] |

| www: | www.turckbanner.co.za |

| Articles: | More information and articles about Turck Banner Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved