HMI systems for marine engine room operation

August 2017

System Integration & Control Systems Design

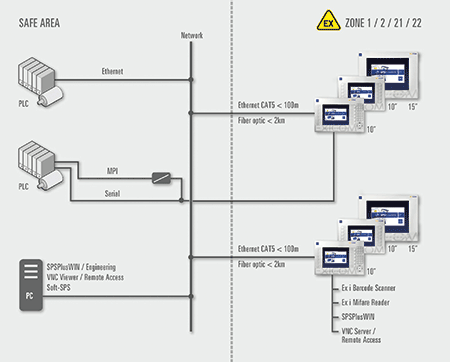

The operating conditions in an engine room posed a particular challenge to the design of an HMI system. These conditions necessitated a closed explosion-protected system that would also be able to withstand the tough marine environment. Flexible panel PC systems using R. Stahl’s Eagle platform will now be used onsite as the ship’s new operating and monitoring systems. With the right interfaces for the application and useful connection options, the series is an asset to both the current and future communication solutions.

These devices also make automation technology easier to use. If the sensors in the engine room below decks need to be recalibrated, for example, this can be carried out onsite on the new operating device.

Designed for maritime use

Panel PCs using the Eagle device platform, with display sizes ranging from 10” to 19”, have DNV, Lloyd’s Register, ATEX, IECEX and ABS certification for use worldwide in hazardous areas and on ships. They are resistant to corrosive gases in accordance with ISA 71.4 G3, have IP66 protection, as well as being vibration-resistant and shockproof.

Their state-of-the-art quad-core processors make them universally suitable for the operation of machinery and processes, as well as in filling stations. All HMIs come with a touchscreen as standard. The 15” device can optionally be fitted with an innovative, sunlight-readable display. The control panel’s add-on modules are able to withstand ambient temperatures ranging from -20 to 55°C. The operating stations, integrated in enclosures, are able to withstand ambient temperatures of between -30 and 50°C, and can be configured in numerous ways.

The seawater resistant materials and the vibration resistant design of the HMI systems, coupled with adequate EMI resistance, make these systems a reliable, durable choice for maritime applications. Owing to the tough conditions in these operating environments, solid state drives (SSDs) are used because they are physically more rugged.

Modular explosion protection

Unlike some standard version panel PCs, the Eagle platform is composed of modules that are individually protected against explosions, allowing users to maintain the devices themselves by swapping out specific individual assemblies as needed. The optimal type of protection for each module has been used: the display module has Ex m protection, others such as CPUs and power supplies have Ex d protection, and connection PCBs feature either Ex e or Ex i protection.

An Ex e ‘increased safety’ terminal box has connection ports for USB 2.0 flash drives, mass storage devices which are very easy to swap out on these boxes. In addition to two standard USB 2.0 interfaces and two intrinsically safe USB 2.0 interfaces, these devices feature two serial ports, a copper or Fibre Optic/Ethernet interface, a connection for keyboards and trackballs (joysticks), and optional interfaces for barcode and card readers. The devices boast all-round IP66 protection and can also be installed as front panel add-on devices without additional protective measures, directly in hazardous areas.

For more information contact Preshan Moodliar, Stahl Esaco, +27 (0)11 608 3120, [email protected], www.esaco.co.za

Further reading:

Modernising Vertical Filter Press Machines with Future-Focused Control Systems

System Integration & Control Systems Design

Project and Industry

Pressure Filter Specialists approached us to modernise vertical filter press machines for the Minerals and Metals industry. The goal was to improve reliability, reduce downtime,

...

Read more...

Project & industry

System Integration & Control Systems Design

Project and Industry

This project involved delivering a complete electrical, instrumentation, and automation solution for a new OEM drum-twister machine, replacing an ageing unit in a major cabling production

...

Read more...

It’s a risky business not to challenge standard language

System Integration & Control Systems Design

On the surface, contracts all look alike. Once you’ve seen one, you’ve seen them all, or so it seems. Maybe so, but hidden within the standard language can be language that shifts the other party’s risk to you.

Read more...

Containerised Electrical & Control System Powers Paste Plant in Botswana

System Integration & Control Systems Design

Delivering a complete, containerized solution for a mine’s paste plant in Botswana, this project stands as a model of modern EC&I execution — integrating electrical, control, and automation systems into

...

Read more...

Control system upgrade: Smelting

SAM Systems Automation & Management

System Integration & Control Systems Design

Systems Automation & Management recently completed a major control system upgrade in the smelting industry. The project was delivered on budget and achieved a positive ROI for the client.

Read more...

Gottwald drives upgrade: Ports and harbours

Abacus Automation

System Integration & Control Systems Design

In the ports and harbours sector, Abacus Automation completed a significant modernisation of a Gottwald crane, improving both operational reliability and serviceability.

Read more...

Mining industry upgrade: From ageing systems to maximum capacity

System Integration & Control Systems Design

Iritron recently undertook a major upgrade in the mining sector, focusing on washing and screening plants, jigs, thickeners, tailings, water systems, conveyors and reclaimers.

Read more...

Agogo Integrated West Hub Project: FPSO/subsea offshore Angola

Moore Process Controls

System Integration & Control Systems Design

The Agogo Integrated West Hub project represents a historic milestone in the FPSO and subsea industry, achieving first oil offshore of Angola. This project is the first FPSO deployment since ANPG’s establishment in 2019, and the first major project for Azule Energy since 2022.

Read more...

Integrated Robotics and Control Systems Deliver 45% Production Boost at Aquazania Waters Project and Industry

Process Dynamics

System Integration & Control Systems Design

Project and Industry Process Dynamics designed and commissioned a state-of-the-art Reverse Osmosis

(RO) water purification and automated bottle filling plant for Aquazania Waters in Linbro Park, Johannesburg.

...

Read more...

Project and Industry

System Integration & Control Systems Design

The Sicomp Control System Upgrade focused on modernising a 1985 power generation control system with more than 3 000 I/O points. The plant faced increasing system failures and risk to operational continuity,

...

Read more...