The demand for reliable data transmission between the harsh industrial environment and the office communication network has recently been increasing. Escha offers appropriate connectivity components for this interface solution. These components include M12x1 round connectors, flanges and built-in plugs with X-coding for the harsh environments experienced in the field, as well as RJ45 connectors for IT wiring.

Connectors for the field level

The four-pair M12x1 round connectors for the field level are based on the 360° shielding concept developed by Escha. Here the shield connection is effected through a reliable crimping with the shield housing and not through a crimped plug-connection on the cable. They meet IP67, IP68, and IP69K protection class requirements and guarantee a safe and reliable 10 Gbit/s data transmission speed according to Cat6A.

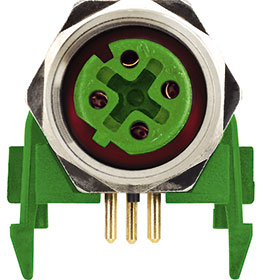

In addition to the manufactured connection and junction cables, Escha has added a field-wireable connector to its product line. The portfolio also includes housing feed-through receptacles for front and back wall installation and an M12x1 flange with angled contacts for direct mounting onto boards. A reflow capable built-in socket for device installation is also available and can be adapted to custom-specific housings. The shielding concept has been implemented with these products as well.

Connectors for the office level

At the office level, sealing requirements are lower than for industry. For this application area various RJ45 solutions are available that meet protection class IP20. The 4-pole and 8-pole connection and junction cables of the RJ45 connector provide for data transmission according to Cat6 and are also available in overmoulded and field-wireable versions. All variants are multi-port capable through their compact housing style.

Applications with high data transmission speeds

In a world of ever-increasing data transmission speeds, Escha’s comprehensive product range for industrial Ethernet applications has the ability to meet customers’ current and future requirements. According to Escha, there are three main industrial areas that require high data transmission speeds. These are building-wide management systems installed in industrial facilities; device installation on the production line; and vision and scanner systems for production monitoring and real-time data evaluation.

In addition to these industrial application areas, there are rail and security applications. Examples are entertainment systems on trains, which provide passengers with a reliable seat-Internet connection, and monitoring cameras, which place similarly high requirements on data transmission and the robustness of the connector.

The trend towards quality is also continuing. High transmission speeds can only be attained when misinformation during data transmission is avoided. In new applications with higher data volumes inferior cables cause transmission errors. This means that data packages have to be resent, which in turn leads to higher network traffic and longer protocol processing periods. Particularly sensitive systems may even experience a bus crash.

Escha has high grade M8x1 and M12x1 industrial Ethernet components for all common Ethernet protocols (Sercos, EtherCAT, ProfiNet, Powerlink and EtherNet/IP). The connector and housing manufacturer has launched connectivity products that provide for measurable, high data transmission speeds. Reliable, fast and safe futureproof data transmission through increased signal reserves is guaranteed.

Comprehensive portfolio for IE applications

Besides the M12x1 connectors with X-coding and the new RJ45 products, Escha continues to offer its proven M12x1 portfolio with D-coding, designed for industrial Ethernet applications with a data transmission speed of Cat5e. This comprehensive 4-pole product range is also based on the proven 360° shielding concept and guarantees better network traffic through high signal reserves.

For more information contact Brandon Topham, RET Automation, +27 (0)11 453 2468, [email protected], www.retautomation.com

| Tel: | +27 11 453 2468 |

| Email: | [email protected] |

| www: | www.turckbanner.co.za |

| Articles: | More information and articles about Turck Banner Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved