Increasing the productivity of the Hulamin foil coater-slitter machine.

Lack of versatility in operation led Hulamin, large-scale manufacturers of rolled and extruded aluminium products, to consider the complete replacement of its old aluminium foil coater-slitter machine.

“This well built machine was limited in functionality due to elements of its mechanical and electrical design,” said Hulamin project manager and coordinator, Leon Potgieter. “In order to achieve improvements in machine throughput, product quality, product scope, serviceability, energy efficiency and production utilisation we opted to upgrade the existing obsolete drives and install additional electrical enhancements for the foil coater-slitter.”

Projects of this nature are commonly outsourced to multinational solution providers since Hulamin considers them to be beyond the scope of the general local skill pool in terms of engineering design and ongoing technical support. “However, we had worked with Abacus Automation on smaller projects in the past and believed that they had the potential to handle a project of this nature,” said Potgieter.

Together with the expertise of drive optimisation, motion control and technology consultants, Exigo Motion Control Laboratory, Abacus presented their proposal to the Hulamin team. “The challenge was to convince Hulamin that we possessed the necessary technical know-how and experience to deliver a solution beyond their expectations. This process involved several presentations to a highly skilled technical team who scrutinised every aspect of our deliverables as well as our technical ability before giving us their vote of confidence,” explained Warren Scott, business development director at Abacus Automation.

“Our solution was purposely designed not to use the proprietary controllers and technology cards that are usual in this type of application,” said Scott. “This option provided an improvement in serviceability and critical spares.”

Challenges

Scott continued: “Maintaining consistent tension on set point throughout the roll diameter at all speeds and during speed changes was key to delivering a high quality solution. Achieving higher processing speeds and extending the capability to handle light gauge foils were also part of the solution design.”

Another challenge that needed to be addressed was the detrimental effect on product quality, throughput, energy efficiency and utilisation caused by the mechanical braking system of the unwind mechanism. Setup and fault finding times also had to be reduced.

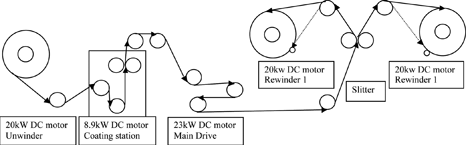

“The machine’s rewinding side was in fact capable of increased throughput but the unwinding side could not keep up. A motor was fitted to the unwinder to replace the water cooled brake and some spare capacity in the main drive and coating station was also utilised to assist the unwind side to cope with the full capability of the dual rewind stations,” said Scott.

Torque and speed control technology using advanced algorithms were programmed into the PLC and drives. The addition of a recipe function allowed shorter setup times and accurate wind to length, while the extensive diagnostics function aided in the reduction of downtime. “Due to production pressures, we had to plan to the nth degree and keep the commissioning time as short as possible. To assist the customer, basic operation was commissioned and production was restarted whilst many of the value added items were commissioned while production continued,” added Scott.

“We were extremely pleased with the outstanding tension control results that were achieved and the dynamic response meant that foil breakage was prevented even during an emergency stop. This resulted in a high quality product and achieving a line speed of 400 metres/minute with the light foil,” said Potgieter.

“Customer requirements called for foil gauges from 38 micron upwards,” explained Scott, “but with minor additional adjustments this was surpassed and product ranges as light as 30 micron are currently being processed since the upgrade.”

“During the extensive consultation process, not only did Abacus and Exigo become entrenched in our production processes, but we also gained a better insight into our own shortcomings and possible areas of improvement. We awarded the original contract for the drive control in 2006 and, due to the success of the project, awarded the team a further project to upgrade the mechanical brake on the unwinder some eight months later,” concluded Potgieter.

Abacus Automation’s company profile can be viewed at: http://www.instrumentation.co.za/news.aspx?pklnewsid=36623

For more information contact Warren Scott, Abacus Automation, +27 (0)31 702 5767, [email protected], www.abacus-automation.co.za

| Tel: | +27 31 702 5767 |

| Email: | [email protected] |

| www: | www.abacus-automation.co.za |

| Articles: | More information and articles about Abacus Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved