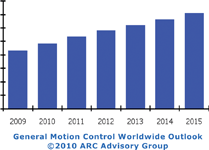

2009 started with the deepest global downturn in recent history. While the worst of the financial crisis may be over, the global recovery remains fragile. With the beginning of the economic recovery, an increasing globalisation environment is expected to resume, which will once again cause industrial companies to invest in new automation equipment in various industries. Although this investment is expected to start at a slow pace, general motion control (GMC) equipment will enjoy moderate growth, according to an ARC Advisory Group study.

Automation suppliers closed the books on a disappointing 2009, and for the near term, at least, suppliers expect the challenging business environment to continue. “Emerging economies in Asia, such as China, India, and a few other Asian countries, continue to make investments in automation as a result of strong domestic demand for production machinery. The growth opportunities in the Asian market will provide motion control suppliers a means to sustain the business until the global machinery market recovers,” according to senior analyst Himanshu Shah ([email protected]), the principle author of ARC’s 'General Motion Control Worldwide Outlook' (www.arcweb.com/res/gmc).

Globalisation will drive GMC market growth

Driven by globalisation, the GMC market will continue to expand on a worldwide scale during the next five years due to a continued infusion of capital for automation in many regions and industries. These include automotive, food and beverage, electronics, and semiconductor industries. The majority of this globalisation is taking place in the countries of Eastern Europe and the developing countries of Asia. Fierce global competition increasingly causes manufacturers to allocate investments in automation to drive down costs and raise productivity by increasing agility and flexibility in their manufacturing operations.

GMC systems play a role in almost every piece of automated equipment aimed at achieving higher agility and flexibility in operations. Manufacturers continually seek ways to increase efficiency and push machine builders to do the same. As a result, new technologies are constantly being developed, making old machinery obsolete and serving as the catalyst for the purchase of new agile, flexible, and efficient machinery. This constant turnover and progression helps drive GMC system growth.

The General Motion Control Worldwide Outlook report also addresses how energy volatility and scarcity, as well as sustainability, are also affecting GMC and automation equipment in a wide range of industries.

GMC suppliers face challenges

Clearly, for automation suppliers, the worst economic period is probably behind them, but one caveat is that new order activity remains sluggish, and will have to pick up significantly for a complete recovery in the automation market. Emerging Asian economies, China, India, and others, provided clear evidence of a recovery for most automation suppliers. The investments in automation continued as a result of strong domestic demands. However, GMC suppliers have a relatively small market in these economies, and therefore the uptick in the Asian market was insufficient to compensate for the severe declines in advanced economies.

In addition to the quantitative assessment of the GMC market, this report provides an insightful analysis of the GMC market and explores issues that will impact this business in the future.

For more information contact ARC Advisory Group, +1 781 471 1000, [email protected], www.arcweb.com

© Technews Publishing (Pty) Ltd | All Rights Reserved