Detection of contamination from heavey metals and organic contaminants

Feb 2000

Analytical Instrumentation & Environmental Monitoring

OEN Enterprisers -

Water contamination can take many forms, therefore the broader the range of contaminants detected, the better the chances are of ensuring uninterrupted plant operation and biomass protection. Traditional laboratory test methods, such as whole organism bioassays and COD testing, can convey an incomplete picture of water quality.

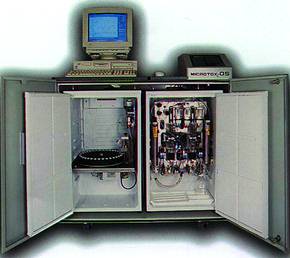

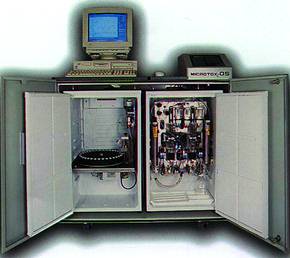

The Microtox-OS test system from Siemens Environmental Systems is claimed to be the only on-line water quality testing instrument capable of detecting contamination from heavy metals, organics, pesticides, and herbicides, among others. This is an important safeguard when the user is trying to optimise plant performance and minimise operational costs. In addition, the system provides the speed, automated sample preparation, toxicity alarms and remote data access that are simply not available in other testing methods.

A test system is only as good as the validity of its test results. This is why the Microtox-OS has multiple crosschecks to ensure reliability of test data.

The first check is an automated biodetector verification (BDV) protocol. The Microtox-OS test reagent is tested immediately upon reconstitution to measure and ensure the response to a given standard. If the reagent vial is rejected, the reagent carousel rotates to the next vial. The BDV protocol can be programmed to execute at user-set intervals - every new carousel, every day, or any interval in between.

The Microtox-OS test system calibrates itself automatically to assure standardised results. Finally the entire system is temperature controlled to ensure stability of the test reagent.

Wastewater treatment plant operators can program the Microtox-OS test system to identify seasonal and operational trends. It can also help plant personnel troubleshoot problems and fine-tune plant operation.

The system incorporates a proprietary learning mode algorithm, whereby the System 'learns' normal baselines for acceptable and unacceptable water quality. Thus, the System allows the user to adjust the internal alarm thresholds accordingly.

Learning mode provides the system with the means to compensate for seasonal water quality changes or industrial production variances. Therefore, heavy stormwater runoff or cyclical spikes in production output will not trigger an unnecessary false alert.

Up to 30 days of data are automatically archived in memory within the Microtox-OS test system. Data can be uploaded via modem to the computer, scada system or monitoring station, allowing the latest data collected from the Microtox-OS test system to be readily available. Data can even be imported into spreadsheet applications such as Microsoft Excel for analysis. This flexibility even allows Azur technicians to remotely troubleshoot, perform diagnostic checks or upgrade software on systems located anywhere in the world.

OEN Enterprises

(011) 792 2859

[email protected]

Further reading:

Precision in every drop, powered by ICP technology

Wearcheck

Analytical Instrumentation & Environmental Monitoring

Elemental profiling using Inductively Coupled Plasma – Optical Emission spectroscopy provides useful information on the chemical composition of lubricants.

Read more...

A trusted oxygen analyser back in action

Elemental Analytics

Analytical Instrumentation & Environmental Monitoring

After a period of discontinuation, Servomex’s Oxy 1810 oxygen analyser has officially returned.

Read more...

Multi-channel pH and conductivity controller for the water sector

Senseca

Analytical Instrumentation & Environmental Monitoring

The measurement of pH and conductivity plays an integral role in water systems. Senseca South Africa has introduced a multi-channel controller that allows the connection of up to five digital sensors and a frequency-emitting flow sensor.

Read more...

DEKRA Industrial sets new standards for asset integrity in local petrochemical sector

Analytical Instrumentation & Environmental Monitoring

DEKRA Industrial South Africa has strengthened its position as a leader in hydrogen-induced cracking inspections through a strategic combination of advanced non-destructive testing techniques, investment in state-of-the-art inspection equipment and global technical collaboration.

Read more...

ABB leads in emissions monitoring with industry-first data acquisition system proficiency test

ABB South Africa

Analytical Instrumentation & Environmental Monitoring

ABB is the first company to offer a complete package of continuous gas analysis and DAHS systems fully compliant with international standards.

Read more...

Ensuring clean and safe water

Endress+Hauser South Africa

Editor's Choice Analytical Instrumentation & Environmental Monitoring

Endress+Hauser’s comprehensive range of disinfection sensors is designed to monitor and control disinfectant levels in water treatment processes.

Read more...

High-precision measurement of insulating gases

WIKA Instruments

Analytical Instrumentation & Environmental Monitoring

WIKA has launched the next generation of its GA11 gas analyser. It enables switchgear operators, manufacturers and maintenance companies to record the quality of SF6 gas and alternative insulating gases.

Read more...

Say goodbye to missed contamination with real-time colour monitoring

Analytical Instrumentation & Environmental Monitoring

Applied Analytics offers seamless and rapid colour monitoring in processes with an industry-proven analyser that quickly and accurately monitors colour in your sample stream for impurities and inconsistencies.

Read more...

Metrology laboratory is the heart of data-driven production consistency

Analytical Instrumentation & Environmental Monitoring

Pressing and welding have been at the core of Tier 1 automotive supplier, Malben Engineering for 50 years; but it is the company’s investment in its state-of-the-art metrology laboratory which has set it apart.

Read more...

Unlocking precision: The future of inline concentration measurement

Analytical Instrumentation & Environmental Monitoring

[Sponsored] In today’s resource-conscious industrial world, manufacturers are under growing pressure to optimise productivity, ensure consistent product quality and minimise waste. One of the most effective levers for achieving these goals lies in mastering concentration measurement, and Anton Paar is redefining how it is done.

Read more...