Silo owner and operator, Vrystaat Koôperasie Beperk (VKB), with its head office based in Reitz, recently upgraded its Reitz silo interlocking system to an LG GLOFA PLC, supplied by LS Industrial Systems SA, and an Adroit scada package.

VKB operates 12 silo complexes in the north eastern Free State with its most visible complex being next to the N3 Highway at Villiers. Werner Swemmer, a member of the engineering staff at VKB, had the following to say. "Having operated the previous Interlocking System at the Reitz silo for over 20 years, the system had been expanded to its maximum capacity and most of the replacement parts had become obsolete."

Modern replacement system

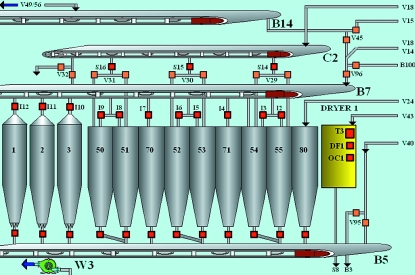

A year ago, VKB management made the decision to go into the market to look for a modern replacement system. It was a requirement that the entire plant be depicted and controlled via scada.

In the process, a number of PLC and scada vendor products were evaluated for suitability. Over and above this, VKB also had to identify a competent integration partner to install, program and commission the new system. Costs, reliability, expandability and minimal down-time of operations were other major considerations, as the changeover had to be completed within one weekend, whilst the silo was still under running conditions.

System integrator of choice

C and H Controls, with Sycann Tulshi as the managing member, was appointed as the system integrator of choice. The system's hardware platform was designed around the GLOFA GM4 PLC, which is offered by LS Industrial Systems SA, while an Adroit scada package was chosen as the medium for depicting the plant and interfacing to the operators.

Phase one of the project required 960 PLC I/O points and a 150-tag scada, which catered for the embedded control of the interlocking and the monitoring of the system.

Factors influencing the decision were the power, ease of programming and the general user friendliness of the PLC system. A further factor was the expandability of the controller for future upgrades, so as to include the full automation of the silo, which will be completed during phase two of the project.

The LG offer included the free-issued programming software for the entire suite of PLC and HMI, as well as the OPC Server for the scada. These were contributing factors to the overall cost effectiveness of the total upgrade. "The new controller has now been in operation for four months and we are extremely pleased with its performance, as well as the support and service we received from C and H Controls and LS Industrial Systems SA," said Swemmer.

When asked to comment on the execution of the project, Tulshi of C and H Controls said: "Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skilful execution. It represents the wise choice of many alternatives. Having implemented the rules for project execution, we minimised our risk and maximised the use of our resources and time, in order to achieve the upgrade within the allotted time and budget. When LS Industrial Systems recently opened its Gauteng Offices in Waterford Office Park, Fourways, Clive Shawe approached me with a view to joining its System Integrator program. After thoroughly investigating its products, I signed up my company. The VKB upgrade soon followed.

"Some of the challenges that we had to overcome included removing the old system and installing the new one, whilst the silos were still operating. We achieved this changeover in two days with absolutely no downtime. Obviously, careful planning and foresight went into this project with good co-operation and understanding between all parties involved.

"Having executed projects primarily with other PLC vendor products, I am extremely pleased with the results of implementing this solution with the LG GLOFA GM4 PLC. We would like to thank our alliance partners LS Industrial Systems for its support which has contributed to the success of the upgrade and look forward to being involved in the process of all future upgrades within the VKB group," concluded Tulshi.

Ana-Digi Systems is the official South African distributor of the PLC, HMI and VFD/VSD products of LS Industrial Systems (formerly LG Industrial Systems). C and H Controls is a specialist in plant-wide automation that offers a wide range of engineering services.

For more information contact Ana-Digi Systems, 021 914 9030, [email protected], www.anadigi.co.za, C and H Controls, 011 312 1686.

© Technews Publishing (Pty) Ltd | All Rights Reserved