Blue Cube Systems is offering a new mineral quantifier. The MQi is designed for installation directly into a stream of dry minerals.

Making use of Blue Cube's unique MMMC (minute-by-minute mineral composition) technology, the MQi can determine the mineral composition in a mineral beneficiation plant circuit.

Pieter de Waal, executive director of the company, based in Technopark, Stellenbosch, says the information provides continuous feedback to operators and management - a valuable tool. "Being able to assess a plant's performance on a minute-by-minute basis makes it possible to substantially improve production efficiency and makes higher recoveries of the valuable minerals possible," he says.

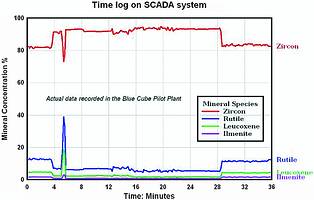

Other benefits include improved plant stability, more consistent grade control and improved flow sheets. According to Francois du Plessis, co-inventor of the MQi, the MMMC technology is based on an optical scanner that detects the 'fingerprint' of minerals flowing through the in-line scanning head. "The complex optical signal is then processed by a spectrometer and converted to a digital format. The dedicated MMMC software, developed by Blue Cube Systems, compares the scan data to the previously stored optical profiles of the minerals expected to be present in the circuit. The MQi will typically display the mineral composition at least every minute and as frequently as every 10 seconds. This enables plant operators to adjust their mineral separation equipment for optimal performance. It also provides industry-standard output signals, which can be tied directly into a plant's scada (supervisory control and data acquisition) systems."

Most mineral beneficiation plants separate and concentrate minerals on the basis of some physical property, such as magnetic properties, conductivity, specific gravity or surface characteristics. De Waal says that it is difficult to quickly determine the composition of a mixture of minerals on the basis of physical properties. The laboratory procedures are too slow to provide adequate feedback or feed-forward for effective process control.

Conventional chemical or X-ray analytical techniques can determine the chemical composition very effectively, but provide very little information on physical characteristics - which are related to the mineral, not the chemical, composition. To date, reliable mineralogical analysis has only been possible through slow and expensive scanning electron microscope (SEM) techniques or by microscopic assessment. The MMMC technology is a substantial improvement on current systems and provides a valuable new tool that can effectively control and optimise mineral separation plants.

Project engineer and co-inventor Van Wyk du Plessis, who was responsible for developing the MQi, expressed great satisfaction with the final product. "Extensive field testing has shown that the careful selection of components and attention to detail in the MQi's robust design makes it eminently suitable for efficient operation in the harsh conditions encountered in an industrial plant."

Blue Cube Systems works hand-in-hand with each client's mineralogists and geologists to identify the types of minerals encountered in their operations. The relevant optical fingerprints are then captured in the MMMC calibration software. The MQi is equipped with a communications device - either a modem or a GPRS - through which remote calibration or software updates can be downloaded. The company offers an ongoing support programme to all clients. It also offers consulting services to assist clients in optimising their plants using MMMC technology. De Waal points out that the company still supplies the MQ-200 bench-top mineral quantifier, based on the same technology.

The MQi mineral quantifier is set to be officially released at the Mineral Processing 2004 conference at the Lord Charles Hotel, Somerset West from 4 to 6 August.

For more information contact Helani Schreuder, Blue Cube Systems, 021 886 7134, [email protected], www.bluecube.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved