Smart manufacturing and digital transformation, coupled with edge intelligence, are enabling manufacturers to increase productivity, reduce downtime, and increase product quality. A key factor in the success of this transformation is the deployment of intelligent edge-computing solutions that can bridge the gap between the operation technology (OT) and the information technology (IT) worlds by providing a number of benefits. In this white paper, we discuss what manufacturers need to benefit from the IIoT trend and how a new generation of IIoT Gateways are helping them reap the benefits thereby trans-forming their businesses.

Reduced latency: manufacturers are expected to be more responsive to customer needs by providing customised products and services on a global scale. In addition, time-sensitive applications need immediate processing of device data to be able to take timely corrective actions and facilitate quick decision-making. Edge intelligence can facilitate quick decision-making at the field sites as opposed to sending all the device data from the edge to the cloud for processing.

Independent remote operations: an edge-computing platform enables remote locations to reduce downtime and operate independently when the central system is inaccessible. For example, if there is a network outage and connectivity to the cloud system is lost, field sites can use local computing power to process and analyse data. Processed data can then be sent to the cloud for long-term storage when the connection is restored.

Data security: sending sensitive operational data from the edge to the cloud puts the data and edge devices at risk. Multiple levels of security need to be put in place to ensure that the data is securely transferred from the edge device to the cloud. Processing data at the edge helps prevent data breaches and enables faster responses.

Reduced data transfer costs: transferring large volumes of data from the edge of the network to a cloud server can be prohibitively expensive. Furthermore, the cost of transferring this data on a daily basis could lead to unsustainable communication costs in the long run.

Manufacturers are looking for optimised computing solutions for their industrial-automation applications to intelligently process large volumes of data received from the sensors and field monitors, and send only critical data or a summary of the data to the cloud. Compact-sized, ruggedised industrial Arm-based computers, designed for low power consumption, are at the heart of these solutions and make edge-side computing more reliable and cost-effective.

Benefits of using an Arm-based Linux IIoT gateway solution

Arm-based Linux IIoT Gateway solutions provide industrial-grade security, manageability, performance, and reliability while still maintaining extensibility. They typically combine the hardware, OS, and software functions listed below to provide an optimised edge-computing solution for IIoT applications.

Longevity: industrial products are usually in place for 10 to 15 years. To meet this requirement, Arm-based CPUs typically come with a minimum lifespan of 15 years. In addition, Arm’s commitment to long-term support and access to their future enhancements, make Arm-based solutions an ideal choice for industrial applications.

Low power consumption: low-power processing is a requirement in many industries to ensure that the equipment does not overheat and pose a potential hazard. Fanless equipment is also preferred so as to mitigate the effects of dust in industrial environments. Arm Cortex-A processors are highly optimised for performance and power efficiency.

Scalability: Linux is eminently scalable and is able to run on a variety of platforms. The basic functionality of a Linux platform – command line tools, configuration, and code – is compatible with any Linux-based device. This flexibility allows for easier upgrades and compatibility between different systems.

Enhanced security: while manufacturers are reaping the benefits of digitisation, they are also faced with data security risks and software-integrity issues. A Trusted Platform Module (TPM) can be deployed to guarantee the physical security of edge devices. In addition, Arm’s TrustZone can be used to create an isolated secure world, which can enhance security and maintain the integrity of edge-computing solutions.

Ready to run IIoT gateway solutions leading the way

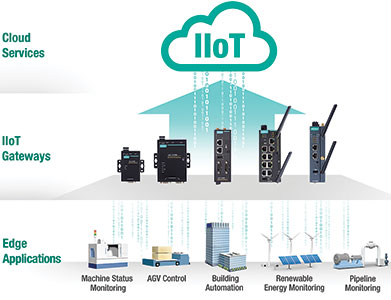

A new generation of IIoT Gateways that are optimised for industrial applications are revolutionising the manufacturing landscape. Built around an open Linux-based platform, these IIoT gateways are secure, industrial-grade computing platforms that support multiple communication interfaces and run on low power.

Industrial-grade Linux

IIoT gateway solutions that include a high-performance industrial-grade Linux distribution and long-term support are better equipped to meet the growing needs of manufacturers. Currently, long-term support (LTS) offered on a Linux kernel is five years. In most industrial establishments, especially in critical systems such as energy, water, transportation and communication, it is not feasible to update the software systems every five years. Software vendors should commit to long-term maintenance of the Linux platform. A long-term commitment (10 years or more) to support a Linux kernel, which includes security patches and bug fixes will address the needs for extended lifecycle of computing systems in industrial automation applications, making industrial projects secure and sustainable. Projects, such as the Civil Infrastructure Platform (CIP), aim to speed implementation of Linux-based civil infrastructure systems, build upon existing open source foundations and expertise, establish de facto standards by providing a base layer reference implementation, and contribute to and influence upstream projects regarding industrial needs. CIP’s kernel will be based on Linux kernel 4.4 and will include security patches and features backported from newer kernels.

CIP is driven by some of the world’s leading manufacturers of civil infrastructure systems and industry leaders including Codethink, Hitachi, Plat’Home, Renesas, Siemens, Moxa and Toshiba. This project is hosted by The Linux Foundation to create an open-source platform for managing and monitoring IoT-enabled civil infrastructure and make it safe, secure, reliable, scalable and sustainable.

Low power consumption

For low-power applications, Arm-based systems are a natural choice. x86-based IIoT gateways consume on an average 30 W of power while their Arm-based counterparts, for example, gateways built on the Arm Cortex-A processor, can provide industrial-grade performance in power budgets under 10 W. Low power computers and devices help substantially reduce your operational costs. They consume less power and hence generate less heat, which means no cooling systems are required.

Secure platform

Operational networks were simply not built for connectivity to the Internet/cloud. The key focus of these networks is quick data access for industrial processes. Manufacturers feel that implementing multiple security levels is a huge drain on network resources and may impact productivity. However, in the IIoT age, where the trend is towards more connectivity for edge devices, which may otherwise never be connected to the Internet, there is a quantum increase in possible attack points for malicious attackers. Security threats can extend to even low-level devices. Cyber attackers can target anything that is exposed to the Internet, including a thermostat in the field to a wireless device. Manufacturers can longer take this threat lightly. Information security, system hardening, security fixes and ability to backport fixes to existing cores without having to change the software, helps organisations better fight cyberattacks.

For example, Arm-based computers that support TPM v2.0: bringing TPM and Arm-based computers together gives system integrators and industrial engineers a powerful new tool in their security arsenal. By creating a specific cryptographic key for each individual device, which is hardcoded within the platform itself, the data stored on the computing system is secured and protected from being read by an unauthorised party. Moreover, the OS on the system can be locked from being overwritten to secure edge devices and data in distributed areas. Security utilities and tools that can conveniently build up the protection mechanism on the software platform to meet your cybersecurity requirements are other ways to secure industrial systems.

Support for multiple interfaces and protocols

IIoT Edge Gateways should come with multiple interfaces such as serial, CAN, Ethernet, Wi-Fi, and 4G LTE. IIoT gateways with carrier (Verizon/AT&T) certifications and industrial-grade CE/FCC/UL certifications enable reliable connectivity for edge devices. Edge-side software that accelerates mass configuration of devices, easy device management, and data acquisition can speed up system deployment. Modbus connectivity for data acquisition and processing and MQTT support for lightweight edge-to-core data transmission reduce development efforts. RESTful APIs and Modbus APIs for implementing gateway software functions enable easy integration with existing systems and with new-age IIoT applications.

Easy connectivity to the cloud

Edge intelligence and connectivity to the cloud are two faces of the same coin. Depending on the IIoT applications, connectivity to a private cloud, public cloud, or both may be required. To enable cloud connectivity and edge intelligence, generic Modbus and EtherNet/IP protocol support, MQTT /HTTPS and RESTful/ C/Python API support are required. Built-in clients for AWS, Azure, Ignition Edge (Sparkplug), and Wonderware Online services may also be necessary, depending on the cloud services that are required for your IIoT applications.

Case in point

The following example illustrates how new-age IIoT gateways can help manufacturers speed up IIoT deployments and transform their operations based on intelligence from field data.

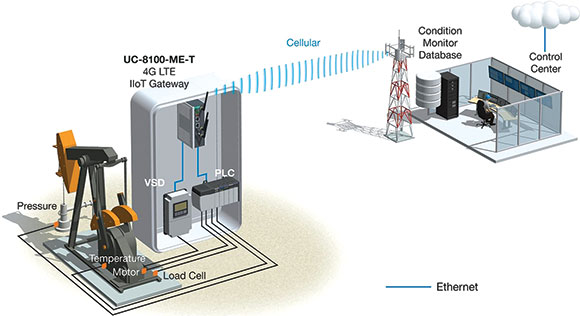

Enabling predictive maintenance in artificial lift monitoring systems

A leading oil and gas service company is building telematics solutions for its customers to run smooth operations and conduct predictive maintenance for artificial lifts in oilfields. With the trend of oilfield digitisation, telematics has been tremendously useful in understanding equipment status so as to avoid problems, also called predictive maintenance. The data generated by the equipment during the operations is the key to achieve this goal. As a result, this oil and gas service company needs a reliable and secure solution to ensure that the data needed is brought back to the control centre for further analysis (Figure 1).

A wireless-enabled Arm-based open computing platform that acts as a secure IIoT gateway, allows oil companies to aggregate data from variable speed drives (VSDs) and PLCs for their pumping systems and to transfer the data back to the control centre through LTE communication in the harshest environments.

A built-in Trusted Platform Module (TPM) in the IIoT gateway ensures that each individual device is hardcoded by a cryptographic key to ensure the data is only accessible by authenticated parties.

System requirements:

• Low power consumption because oil wellheads are often located in harsh environments where powering is sometimes difficult.

• Reliable 4G LTE connectivity in high operating temperatures for constant data aggregation.

• Computers must feature Trusted Platform Module (TPM) to ensure data integrity.

• Open Linux platform for flexible application development.

Moxa’s wireless-ready IIoT gateway solutions

Moxa’s UC series IIoT Edge Gateways are industrial-grade, wireless-ready Arm-based computing platforms that are designed to operate reliably in a temperature range of -40 to 85°C. These gateways are built around the Arm Cortex-A processor and come with Moxa Industrial Linux (MIL) to address the need for extended lifecycles in computing systems for sectors such as solar/wind power, water and wastewater, oil and gas, transportation and factory automation. Key benefits include:

• Industrial-grade Linux.

• Low power consumption.

• Secure platform.

• Support for multiple interfaces and protocols.

• Easy connectivity from the edge to the cloud.

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

© Technews Publishing (Pty) Ltd | All Rights Reserved