In part 1 (August SA I&C) we looked at mill information technologies and how ERP and MES systems need access to real-time plant information before they can contextualise and report. In part 2 we study the importance of enterprise asset management in the pulp and paper industry.

Today’s economic outlook calls for critical access to information to maintain viability across most of our industrial environments. The pulp and paper industry is no exception. In times where access to capital for new project investments can be difficult, all investments need to deliver above average returns. Mill information technologies are no different. The need to have accurate information on the performance and reliability of each piece of equipment (asset) is essential.

The development of and need for real-time asset management

Enterprise asset management systems are used across a broad range of process industries. Maintaining processes and systems has evolved dramatically over the years with the emergence of condition based monitoring programs. In the early years, maintenance consisted of reacting to mechanical breakdowns. As technology progressed, maintenance workers strove to perform time-based preventive maintenance. Gradually this method evolved into a condition-based maintenance. Today, effective maintenance systems are expected to detect early signs of degradation in order to initiate predictive maintenance practices.

A proactive approach that can identify maintenance problems before they become critical makes good business sense. The use of the PI System software for any condition based maintenance (CBM) initiative helps users identify incipient faults before they become critical. The economic relationship between fewer breakdowns and more uptime is obvious, yet CBM has not been embraced by the pulp and paper industry in the same way as other programs such as Six Sigma. Why not?

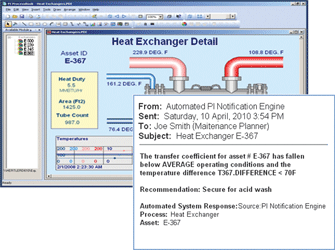

One common perception that is incorrect is that CBM solutions require new technologies and cannot work with older systems. Many manufacturing companies are not prepared to retire systems if they still work well. Rather, they want to use the equipment more efficiently, extend the equipment’s life, and improve its performance. The OSIsoft PI System offers a simple, supportable and expandable CBM solution that leverages data collected from disparate sources by determining anomalies, creating an alert and presenting this in a variety of formats that can be customised to individual needs. With the addition of an effective strategy for notification, it is possible to create an effective CBM solution.

The bulk of the work needed for an effective PI-based CBM strategy is not found in software configuration alone, it is driven by which equipment to tackle first. To plan for a CBM implementation across an entire mill at one time would likely result in failure and unmet expectations. A better approach is to examine which assets are mission critical to production and build a set of PI-based rules around those assets first. A second approach is to examine previous maintenance expenses and select the top 15-20 assets with the highest year-on-year maintenance costs. By selecting a subset of the total assets in a mill and putting a CBM program to work across those assets first, the mill can test its readiness for the program and gain user buy-in early, to fuel the future expansion of the CBM initiative.

While there are many strategies for selecting which assets to work on first, the CBM methodology involves the following four steps:

1. Connect and collect all data available from the monitored systems and devices (the PI infrastructure).

2. Select the initial assets to monitor.

3. Determine types of information needed, methods of analysis and the business rules that will be used to report an operational anomaly or incipient failure.

4. Create the actionable conditions (PI calculations) to bridge the gap to the ‘consumer’ of the information for action (whether that involves a visual dashboard update, an email to a maintenance planner, or an automated creation of a work request in the company’s maintenance management software system).

OSIsoft’s PI System investment enables staff to connect in real-time to all the mission-critical information needed to launch an effective CBM program. By implementing a CBM solution as a natural extension of the PI System, users will be able to reduce costly emergency work, decrease downtime, increase work effectiveness and ultimately lower maintenance costs.

The competitive advantage many paper companies strive to gain can be found in the collection of data from a disparate source to provide real-time enterprise asset knowledge using CBM. The data history and presentation of PI System information that mill management can utilise, creates high value opportunities in today’s global economy.

In Part 3 we will look at the importance of managing production variable costs.

Readers wanting more information on OSIsofts PI system can visit: http://instrumentation.co.za/+C14093A

For more information contact Nick Stead, OSIsoft, +27 (0)31 767 2111, [email protected], www.osisoft.com

© Technews Publishing (Pty) Ltd | All Rights Reserved