Today’s economic outlook calls for critical access to information to maintain viability across most industrial environments. The pulp and paper industry is no exception. In these times, where access to capital for new project investments can be difficult, all investments need to deliver above average returns. Mill information technologies are no different in this regard. Technologies like ERP and MES are well known as tools to streamline business processes, but they need plant information before they can contextualise.

Perhaps the most important criteria for selecting a company’s IT data infrastructure system is its capability to meeting current needs while ensuring it can easily and cost effectively adapt to future requirements. ERP and MES systems are highly dependent on access to reliable real-time data. In many paper mill environments this data is often challenging to collect and verify for accuracy. It is often sourced from a myriad of interfaces including distributed and quality control systems, laboratory systems and manual collections. A well-implemented process information infrastructure, like OSIsoft’s PI System, can unlock hidden mill capacity, reveal areas of energy waste, minimise down time and deliver material consumption and production information in a timely fashion to the ERP system, helping to maintain mill viability and customer satisfaction.

How is this accomplished?

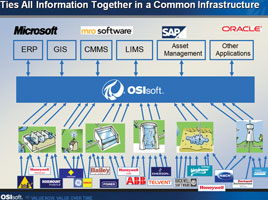

Rather than investing heavily in new network and IT equipment, the investment should concentrate on bringing together information to solve business problems. Management may need to change the thinking to ensure that information is presented and used as a common infrastructure across all mill assets. Today, many paper companies have over capacity; increasing production has become less important and strategies that help mills maximise profitability are the new priority. The key is for the mill to use integration that will provide maximum value from its existing system and data assets.

The first part of this article focuses on how mill managers can use OSI’s PI System software to optimise operations and improve business performance.

Turn mill data into actionable information

What visuals, alerts, or reports do you use in your mill to convey a need for action? Is your company monitoring key performance indices (KPI) that predicts or detects production anomalies ahead of time? Do you use a morning meeting to schedule a ‘plan of attack’ to get processes back ‘in control’? In 2008, our industry created, displayed and stored more data than in all of preceding history. However, it is questionable if our manufacturing efficiency increased significantly. The paper industry, like its sister process industries, is facing extraordinarily challenging times. Data overload, combined with an increasing number of retiring skilled workers, addition diverse assets due to company consolidations, a growing number of governmental regulatory and environmental mandates and overall industrial decline have hit paper companies particularly hard.

To create more competitive and profitable mills, manufacturers must begin managing data and turning it into real, actionable information. Large capital expenditures to replace the current quality and control systems in the mill are rarely cost effective or practical. The large number of diverse process steps in the various parts of a fully integrated pulp and paper mill create the need for multiple control systems and strategies, leaving the mill with multiple control system vendors and technologies and creating islands of automation with disparate data sets.

Mills need to manage data from various sources in a structured framework, collate and verify its accuracy and present it in a form enabling rapid and timely decision making. The new technologies for portal environments, like Microsoft’s SharePoint or SAP’s Enterprise Portal, provide frameworks that can be both validated and ‘locked down’ while remaining flexible and easy to configure. The PI System provides a user interface to run in either environment and is commonly used to provide valuable dashboard information around actionable metrics while also providing the drill-down capability needed to get to the source of a problem or anomaly.

Many PI customers in the paper industry today are intelligently using data and creating highly automated systems to combine information from multiple mills across their respective organisations. These dashboards are easy to navigate and provide seamless connectivity across diverse assets. Effective corporate or even mill-wide dashboards can be an optimal venue for comparing and tracking production metrics so that problems can be detected and corrected before a failure occurs. KPI charting can provide valuable insight into performance of assets and their comparison to other assets running under similar conditions. This type of information can help managers identify the ‘Best Practices’ to be deployed across the organisation and also determine which equipment runs best in which environment.

The competitive advantage many paper companies strive to gain can be found in the collection of data from disparate sources. The data history and presentation of PI System information that mill management can utilise, creates high value opportunities in today’s global economy.

In Part 2 we will study the importance of enterprise asset management in the pulp and paper industry.

Readers wanting more information on OSIsoft’s PI System can visit: http://instrumentation.co.za/+C14093A

For more information contact Nick Stead, OSIsoft, +27 (0)31 767 2111, [email protected], www.osisoft.com

© Technews Publishing (Pty) Ltd | All Rights Reserved