Flue gas analysis

December 2000

Analytical Instrumentation & Environmental Monitoring

Hans Hitzeroth, Unitemp

South Africa is in a catch-up phase regarding efficient energy use and pollution control. Pressure is mounting on industry and local authorities to 'clean up their act' by monitoring and controlling harmful emission from combustion processes.

Fortunately, the necessary instrumentation has become more versatile and compact, making the task easier.

Typical applications for flue gas analysis include boilers, burners, furnaces, power stations, incinerators and heating systems using gas, oil or solid fuels.

Gases that require monitoring during combustion are:

CO2: Carbon dioxide is the result of complete combustion. The maximum achievable concentration (CO2 max) depends on the fuel being used. CO2 monitoring provides a measure of combustion efficiency.

CO: Carbon monoxide originates from incomplete combustion. The gas is colourless and odourless and is extremely dangerous for human beings (a concentration of 12 500 ppm leads to death within a few minutes). Reasons for CO emission are lack of air, excessive airflow or too-early cooling of the flame.

C: Carbon-C results from incomplete combustion and soots up the chimney.

CxHy: Unburned hydrocarbons are formed due to incomplete combustion and contribute to the greenhouse effect.

O2: Oxygen is consumed during combustion. The remaining oxygen is a measure of combustion efficiency.

N and NOx: In case of high temperatures, nitrogen combines with oxygen, forming nitrogen oxide. This is a respiratory poison damaging the lungs.

SO2: Sulphur dioxide is formed during combustion of coal and oil. If the flue gas temperature drops below the dewpoint, sulphuric acid is formed which soots up the chimney and pollutes wastewater.

Changing the measuring cells is as easy as changing a rechargeable battery. Thanks to the built-in electronics, the measuring cells are immediately ready to operate, saving you service costs

Some parameters related to flue gas analysis are calculated from the above measurement results. These include:

QA: Flue gas heat loss.

l: The ratio of excess oxygen to the theoretical air requirements.

effn and effg: Net efficiency and gross efficiency relate to the calorific value of the fuel and the latent heat of water vapour contained in the flue gas.

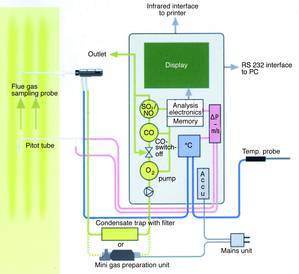

The trend in development and manufacture of flue gas analysers is towards smaller and more complex measuring instruments. Modern instruments use location-independent condensation traps and filters to protect the cell. New electrotechnical gas sensors provide rapid availability of the measured values, small space requirements, maintenance by the user and low manufacturing costs. However, a great deal of development work is necessary to create suitable measuring cells. Allowance has to be made for cross-sensitivity. The layout of the gas path is a major consideration when designing portable flue gas analysers. Another practical aspect is the ease of replacement of cells.

The Festo 300's external connections

A leading manufacturer in this field is Testo (Lenzkirch, Germany). 70% of their turnover comes from products that are not older than three years, showing clearly the innovation power and pace of progress being made. Testo specialises in portable instruments. The range includes entry-level units for single gases to highly complex systems for longer term monitoring of power stations above 500 kW. Testo offers a two-year warranty on its flue gas analysers. To the customer this represents a significant saving in maintenance costs. Testo will also provide a service for measuring instruments that are up to 15 years old.

South African companies that have benefited from Testo flue gas analysers include Iscor, Polifin, Steinmüller, various Technikons, Daimler-Benz and Volkswagen.

Further reading:

Precision in every drop, powered by ICP technology

Wearcheck

Analytical Instrumentation & Environmental Monitoring

Elemental profiling using Inductively Coupled Plasma – Optical Emission spectroscopy provides useful information on the chemical composition of lubricants.

Read more...

A trusted oxygen analyser back in action

Elemental Analytics

Analytical Instrumentation & Environmental Monitoring

After a period of discontinuation, Servomex’s Oxy 1810 oxygen analyser has officially returned.

Read more...

Multi-channel pH and conductivity controller for the water sector

Senseca

Analytical Instrumentation & Environmental Monitoring

The measurement of pH and conductivity plays an integral role in water systems. Senseca South Africa has introduced a multi-channel controller that allows the connection of up to five digital sensors and a frequency-emitting flow sensor.

Read more...

DEKRA Industrial sets new standards for asset integrity in local petrochemical sector

Analytical Instrumentation & Environmental Monitoring

DEKRA Industrial South Africa has strengthened its position as a leader in hydrogen-induced cracking inspections through a strategic combination of advanced non-destructive testing techniques, investment in state-of-the-art inspection equipment and global technical collaboration.

Read more...

ABB leads in emissions monitoring with industry-first data acquisition system proficiency test

ABB South Africa

Analytical Instrumentation & Environmental Monitoring

ABB is the first company to offer a complete package of continuous gas analysis and DAHS systems fully compliant with international standards.

Read more...

Ensuring clean and safe water

Endress+Hauser South Africa

Editor's Choice Analytical Instrumentation & Environmental Monitoring

Endress+Hauser’s comprehensive range of disinfection sensors is designed to monitor and control disinfectant levels in water treatment processes.

Read more...

High-precision measurement of insulating gases

WIKA Instruments

Analytical Instrumentation & Environmental Monitoring

WIKA has launched the next generation of its GA11 gas analyser. It enables switchgear operators, manufacturers and maintenance companies to record the quality of SF6 gas and alternative insulating gases.

Read more...

Say goodbye to missed contamination with real-time colour monitoring

Analytical Instrumentation & Environmental Monitoring

Applied Analytics offers seamless and rapid colour monitoring in processes with an industry-proven analyser that quickly and accurately monitors colour in your sample stream for impurities and inconsistencies.

Read more...

Metrology laboratory is the heart of data-driven production consistency

Analytical Instrumentation & Environmental Monitoring

Pressing and welding have been at the core of Tier 1 automotive supplier, Malben Engineering for 50 years; but it is the company’s investment in its state-of-the-art metrology laboratory which has set it apart.

Read more...

Unlocking precision: The future of inline concentration measurement

Analytical Instrumentation & Environmental Monitoring

[Sponsored] In today’s resource-conscious industrial world, manufacturers are under growing pressure to optimise productivity, ensure consistent product quality and minimise waste. One of the most effective levers for achieving these goals lies in mastering concentration measurement, and Anton Paar is redefining how it is done.

Read more...