Telecommunications project house, Q-KON, has successfully commissioned a state-of-the-art communications system at Amplats' Waterval Smelter near Rustenburg.

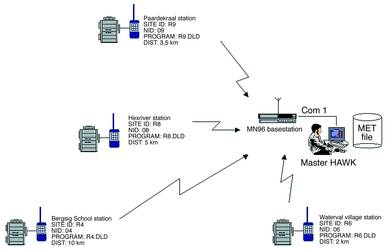

The system provides communication between a basestation and four remote sites capturing readings from measuring instrumentation. Technology Services International, who supplied the monitoring equipment and data loggers for the project, awarded this contract to Q-KON. The software was created by Environmental Management Services and has been designed to collect and process data via Q-KON's communications system.

Q-KON installed MN96-M data radios with power supply units at both the remote and base stations. Integrated with the Motorola GM350 radio the MiniNode radio modem is a complete data radio for rugged mobile and fixed installation applications.

The MiniNode MN96 is a microprocessor-based 9600 bit/s radio modem designed for use in mobile data and remote data collection systems using conventional land mobile radio equipment. Based on Q-KON's successful MiniNode I product, the MiniNode MN96 features enhanced radio data transmission capabilities.

The MiniNode MN96-M provides an RS232 serial data communication port that can be integrated with any serial field instrument or DTE device and a four-signal interface to be integrated with a data radio. Using the latest development in FSK modulation techniques the MN96 modulates the data signal onto a conventional radio channel at 9600 bit/s using a 12,5 kHz bandwidth channel and 19 200 bit/s using a 25 kHz bandwidth channel. It was specifically designed to provide a seamless and direct integrated solution for different applications.

The previous typical configuration system at the Waterval Smelter was developed to operate on a polling protocol. Q-KON has now replaced this with a custom-developed network protocol based on the Carrier Sense Multiple Access with Collision Avoidance protocol.

This means that any remote radio can transmit data whenever a determined period of silence has lapsed. Should two radios begin transmission simultaneously, the master station will detect the collision and will not transmit an acknowledgement message. The two radios will cease transmission for a random period before attempting to transmit again.

Q-KON Corporate Manager, Dirk Staal, says: "By implementing this protocol, we have achieved reliable data transfer between the remote radios and the master. Only one data radio is able to access the RF network at any given time, preventing RF collisions, but all the data radios have the opportunity to transfer their data in good time."

Established in 1988, Q-KON is a wholly owned private South African company concentrating on the supply of telecommunication products and services to the corporate, telecommunication and government market. A Radio Systems Project House, its strength lies in its system engineering and telecommunication-engineering expertise provided to clients in the form of engineering services or product and turnkey supplier services.

Currently, Q-KON is structured in the following business units: telecommunication projects, mobile radio solutions and RF networking solutions; each of which is supported by a range of specialised products and services.

© Technews Publishing (Pty) Ltd | All Rights Reserved