It is not common knowledge that the harshest environments for instrumentation occurs not in the automotive or mining industries but in that of food and pharmaceutical related processes. Water, aggressive cleaning agents and chemicals under high pressures and temperatures form a vicious combination that penetrates almost any instrument housing, causing electronic circuits to fail.

In food related industries, it is quite common to use as a standard, cleaning processes known by the abbreviations, SIP (sterilisation in place) or CIP (cleaning in place). They identify cleaning and sterilisation processes within enclosed installations with cleaning or disinfecting solutions circulating in the process or system. Temperatures up to 140°C may occur for short times. Instrumentation, typically found in packaging areas, is usually not directly in contact with the cleaning agents found in CIP, but it will most certainly be treated by another cleaning process called washdowns. Here machinery and equipment are frequently cleaned by means of high pressure hosing with various kinds of aggressive cleaning agents, chemicals and hot water.

When taking into account the severity of the abovementioned applications, it will come with no surprise that special materials are needed, not only to withstand the damage CIP will cause, but also the compatibility of the various materials used to manufacture sensors intended for these environments. The best metal alloy to use in these kinds of applications is with no doubt 316 stainless steel.

Of course, it is not always possible to manufacture complete instruments of metal and there is no way around the fact that some sort of plastic will come in contact with food processes. For this reason, a very specific type of plastic, called polyether-etherketon (PEEK) should be used. The characteristics of this plastic are unique in the sense that it is the only plastic that is stable under temperatures up to 260°C, making it very compatible for use with stainless steel, as the connection between the two materials is not influenced by temperature changes. It also carries approvals by EEC directive 93/9/EEC for plastic in contact with food and directive 20-19 for multiple contacts with dairy products. Along with that, it carries the WRCA BS 6920 approval for non-metallic materials in contact with drinking water and the requirements of FDA (Food and Drug Association) regulation 21 C.F.R. 177.2415 for contact with food.

In comparison to metal, ceramic and standard plastics, PEEK is more expensive but easier to produce and process. It has a lower weight, a longer lifetime, higher performance and does not give colour off that can possibly end up in the manufactured product, thus making PEEK the obvious choice for the leading manufacturer of IP69K rated sensors.

The ingress protection rating according to IEC 529 or DIN 40050, defines the degree of protection from ingress of dust and moisture into sensors. According to IP68, equipment is suitable for prolonged submersion in water under conditions specified by the manufacturer. This rating, that only emerged around the year 1996, was briefly the preferred rating for the food industry but it was quickly realised that although an excellent rating, it was only good in an application where sensors were mounted around 1 to 2 metres under water.

Of course this kind of application very rarely, if at all, exists. As soon as moving liquid, as seen in washdown applications, comes in contact with these sensors, ingress of moisture still occurred. This was a hard awakening for the food industry and it was realised that IP68 was only good for submersion where no real pressure was applied to the sensor. A new rating was needed where pressure and high temperature could come into the equation. IP69K (usually accompanied by an IP68 or IP67 rating) offered exactly this by having complete protection against ingress of water during high-pressure steam cleaning. It first appeared in 1997 and was initially found in connectors for instrumentation.

Very important to note is that it is of no use to have sensors that are well protected and then to have a shortfall when it comes to the connecting cable. It is just as critical to make sure to use PVC cables tested to 100°C with stainless steel coupling nuts that comply with IP69K. Although some manufacturers use PVC cable, it is not always tested for 100°C and the connector heads are manufactured from PUR.

IP69K then only reared its head again in the year 2000 when German-based company, IFM Electronic, designed and manufactured proximity switches known as its Efector m range of sensors. Then again in 2001 when the same company released a range of photo-electric sensors. Today, it is becoming more common for other sensor manufacturers to latch on to the IP69K rating, but with some differences in their diversity of testing.

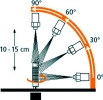

IFM Electronic makes use of the services of ECOLAB (the global leader in commercial cleaning and sanitising solutions) to test its sensors for conformity to IP69K according to DIN 40050 part 9. The goal of this test is to duplicate pressure cleaning conditions on a plant floor. In the test fixture, as can be seen in Figure 1, sensors are exposed to a water jet of 8 to 10 MPa at a temperature of 60 to 80°C on a turntable rotating at a rate of 5 revolutions per minute. The duration of each cleaning cycle is 30 seconds and the test is performed at specified angles through spray nozzles located at a distance of 100 to 150 mm from the sensor. The water aimed at the housing must not have any damaging effect on the sensor.

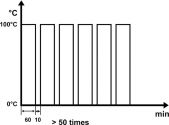

Another test, uniquely performed by IFM Electronic on its IP69K sensors, is the temperature shock test. According to Figure 2, this test entails that a sensor is submerged into water at 100°C for a duration of 1 hour. The sensor then immediately gets placed in an environment of 0°C for a period of 10 minutes. This process gets repeated for more than 50 cycles.

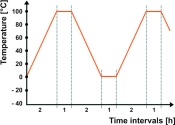

A further test performed by IFM Electronic is the 1000-hour cycle test (Figure 3) where the temperature ramps up from 0°C to 100°C over a period of 2 hours. The temperature then remains there for 1 hour and then ramps down to 0°C again. This process carries on for a total of 1000 hours. 0% failure is the only result acceptable.

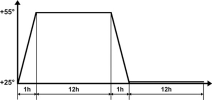

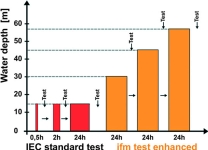

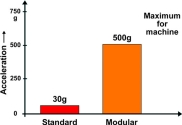

In the humidity test according to IEC (Figure 4) a sensor gets placed in a climatic cabinet under 95% humidity, and in the immersion into liquid test according to IEC 68-2-17 (Figure 5), they require the sensor to be placed under 15 m of water for 30 minutes and then tested. Only sensors that are still operational will be placed under water for 2 hours. If still operational the sensor gets placed under water for 24 hours. IFM Electronic recorded a 30% failure rate for this test on standard sensors from all manufacturers. IFM Electronic enhanced this test by starting off with a depth of 30 m and kept the time constant at 24 hours. Eventually the company increased the depth to around 57 m. Again, 0% failure is the only acceptable result. Lastly, the shock test (Figure 6) entails a test of only 30 g acceleration but IFM Electronic tests under maximum machine performance namely 500 gs.

It is important to realise that the market now offers a wide range of sensors that can actually resist the harsh environments commonly found in the food and pharmaceutical industries. Second to this, it is important to note that manufacturing specifications do differ from company to company when it comes to ingress protection ratings and that it is not required to apply all the abovementioned tests to obtain a IP69K rating for sensors or other equipment.

About the author

Chris Huxham finished his engineering studies at the Vaal Triangle Technikon in 1995 and then worked in the field of instrumentation for four years at a stainless steel manufacturing company. He then joined Pretoria-based company Shorrock Automation and after completing his B.Com Marketing Management degree at UNISA, he now holds the position of marketing manager. One of Chris' main functions is to specialise in the food and pharmaceutical industries.

For more information contact Chris Huxham, Shorrock Automation, 012 345 4449, [email protected], www.shorrock.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved