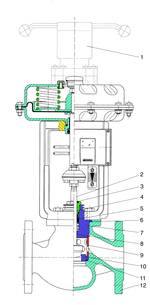

The valve series Arca-Ecotrol is a rugged, compact and light weight control valve with a pneumatically operated, easy field reversable multi-spring diagpragm actuator(Arcapaq 812) and a sturdy, tubeless and vibration-resistant mounted digital positioning(Arcapro 827).

Optionally, the actuator can be equipped with a fully encased and protected emergency handwheel which is in accordance with safety precautions. The high-light of this valve series is the Arca-double-life SWS (quick-changeable trim combination) with the allowance of double-side use by reversing the seat ring. The plain geometric design of the valve seat permits many economical options in materials to be used for seat production, for example steel, hardened and stellited, ceramic, tungsten carbide etc, with or without soft seat sealing.

In comparison to conventional construction, the PTFE-soft seat element is held by an elastomer O-ring and not placed in the valve plug, as usual, but rather in the valve seat. The mechanical end stop at the metallic sealing edge in combination with the back-up O-ring guarantees that the double-side usable PTFE-sealing ring will not be deformed by excessive thrust-force.

The remarkable difference between the common screwed-in seat ring and this unique quick-change(able) drop-in seat shown in the figures on hand is the method of fixing and sealing of the seat ring in the valve body. With a screwed-in seat ring the sealing between seat and valve body is metallic against a conical face. The conical counterface in the valve body has a slightly different angle so that theoretically there is only a line contact. The required torque to screw-in the seat ring varies depending on the construction and the operating conditions. With the Arca-Ecotrol valve series the seat sealing is done purely axial and controlled by the method of initial compression to eliminate the possibility of an overcompression.

The compression of the sealing elements is limited by the precisely sized mechanical end stop. This guarantees the necessary compression of the seals and results in accurate alignment between the sealing surfaces of plug and seat ring.

The self-aligning seat ring is held by the retainer. Tightness will be achieved by the transmission of a portion of the bonnet-to-body bolting force via the retainer to the seat ring. The manufacturing of the valve body, retainer and seat ring is done by means of special CNC-machining centres to attain the necessary tolerances. This guarantees the required compression of the sealing elements. Effective guiding of the shaft is performed by two special guide bushings located far apart from each other.

The pressure activated valve stem seal has an added micro-sealing element and additional wiper ring. The PTFE-V-Ring packing is pressed by the force of the corrosion resistant spring against the valve stem and the insert of the bonnet. This packing assembly acts as a primary sealing and as a scraper. The valve stem is double-guided right before and behind the packing. The result is reliable sealing over a wide temperature range and less static and sliding friction than conventional stuffing box packings.

The standard bonnet (DN 15-65/1/2-21/2') has cooling fins to provide a regulated temperature drop between the cold or hot fluid and the temperature of the stem sealing.

Choice of extended bonnet for protection of the stem sealing against extreme fluid temperatures and the inclusion of heating jacket (thermal fluid between body and jacket) is available on request.

| Tel: | +27 31 579 2593 |

| Email: | [email protected] |

| www: | www.valve.co.za |

| Articles: | More information and articles about Valve & Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved