CS Systems Integration, a division of CS Holdings, chose Wonderware’s InTrack solution as part of an extensive and integrated nationwide Distribution Tracking System (DTS) for Delta Motor Corporation.

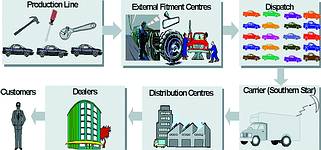

Delta Motor Corporation, the motor manufacturer based in Port Elizabeth, boasts a countrywide distribution network of assembled vehicles that extends across several right-hand-drive African countries, including Zimbabwe, Mozambique, Malawi, Zambia and Mauritius.

Delta and its carrier company, Southern Star Organisation (SSO) decided to embark on a strategy that would result in reduced delivery lead times, Internet-based order and shipment tracking as well as lower distribution costs through a new distribution tracking system.

The system is implemented as a nationwide, intranet-based solution with a data centre based in Port Elizabeth. The DTS integrates, in realtime, with two-way transaction flow between SAP R/3, the mainframe, the production plant InTrack systems, the logistics systems at SSO as well as batch scanners and single scanners at the depots and fitment centres. Its integration engine allows for Delta or SSO to change other components of their software without having to change the DTS.

"The DTS has provided a realtime, nationwide, low administration, integrated solution to Delta's distribution tracking problems," says CS Holdings, divisional director Danny Naidoo. "The use of thin-client architecture allows for the nationwide system to be administered from the data-centre in PE or wherever the administrator prefers. A node's functionality or identity is data-driven so that it can be changed and, by so doing, adopt a different set of functionality if the need arises. A realtime, secure, thin-client, tracking system with an integration engine that is configurable and that caters for changes in the interacting systems as well as in business process requirements, can only be described as a uniquely innovative application."

The system can also help to minimise corruption at the import/export stage of a vehicle's life as the documentation is now produced by the DTS at the customs bond store with the vehicle present. This helps to eliminate tampering with VIN numbers and other information.

By integrating Delta's SAP R/3 and production plant InTrack systems through the DTS, there is now one single source of data for a vehicle in the distribution stage of its life and this can be redefined if the vehicle returns to Delta even after several years of being sold and being in use. The mainframe-based systems and SSO's operations systems all have the same distribution information as SSO's billing and transactions are now entered into Delta's SAP installation seamlessly and accurately.

The DTS was developed using InTrack, MS SQL Server, MS IIS and Seagate Crystal Reports with C/C++ components for the bar code scanners, VB and ASP for the user interfaces and VB for the integration engine and the InTrack transaction processing engine. The application had to allow realtime scanning of barcodes across the network for sites around the country, with the data centre located in Port Elizabeth. The system had to provide rapid responses as the depot staff are under constant pressure to increase shipping throughput.

According to Guy Vellacott, general manager information technology at Delta Motor Corporation, "the implementation has made a significant difference to Delta's ability to manage its business in a more effective, realtime manner. Improved control, audit trails and management information mean we have a more effective means of tracking and predicting production and delivery, and our ability to make promises to customers is also significantly improved."

Vellacott says the new tracking system enables the vehicles to be accurately monitored at each stage of the distribution. "We now have better control over SSO as far as the speed and quality of their performance is concerned. "Additionally, statistics on vehicle damage are also readily available, as is information on vehicle delivery to dealers. The fact that we now know where the vehicles are at any given point means we have better control over returned vehicles and are able to make more reliable promises to our customers regarding the delivery of newly purchased vehicles."

"The system has resulted in one version of the truth for the distribution of vehicles from Delta," continues Naidoo. "The lowered costs of maintaining vehicles that have been in distribution for too long and greatly improved tracking facilities have all resulted in significant savings. SSO now has the same distribution data as Delta and there is no longer any need for time-consuming reconciliations. A stock-take of the depots and fitment centres is now done in less than a day as opposed to several days and involving several dedicated personnel as in the past. Errors are minimised since data is not re-entered but simply scanned, checked and verified. All-in-all, a highly successful implementation with important business benefits for Delta as well as for its customers and business partners."

For this DTS implementation, CS Systems Integration received the X-CHANGE 2002 Wonderware Open award for Best InTrack application.

For more information contact Mike le Plastrier, Futuristix, 011 723 9900, [email protected], www.futuristix.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved