The main objective of the fountain inside the Century City shopping mall, near Cape Town, is to attract people. The control equipment needs to be flexible, reliable and easy to maintain. A computer-based solution was considered the best option. The computer eases the human interface, as PC-based HMI allows people to clearly see what they are doing, and the fountain is also able to function automatically.

Laid out in the form of a clock, the fountain indicates the time in five-minute increments. Time indication is accomplished by 12 water nozzles representing the different positions of an hour hand and another 12 representing those of a minute hand. In the middle is one large nozzle with a high and low mode. This is used to indicate the hour, or that 12 hours have lapsed.

Operation of the fountain is simple. It supports two modes: realtime and a sequential mode. In realtime mode, the fountain displays the current time by making use of the different nozzles as different hand positions. The time is updated and displayed in five-minute increments, with the hour and minute nozzles producing water jets running through a sequence of positions corresponding to the hands of a clock. The middle nozzle is used to announce the hour, much like the bird in a cuckoo clock.

In the sequential mode, the fountain displays a water jet sequence. Different preset groups of nozzles are activated at defined interval periods, following a 'choreographed' sequence. This mode generates many interesting water sequences - one, for example, imitates a rotating wagon wheel.

The minute nozzles are fed from one large pump with individual valves to select different nozzles. The hour nozzles on the other hand have individual pumps. The centre nozzle has two pumps (producing low and high flow rates). The fountain set-up also includes filter pumps that are used to filter the water. Another two valves are used to refill the pond or to empty it. The pond is also equipped with water level sensors. The valves are switched directly by solid-state relays. The pumps are buffered through contactors to increase the switching current. The level sensors are monitored through an optically isolated input board.

Water level monitoring has to be effected to ensure water levels suitable for satisfactory operation. (If the water level drops too low, the pumps will run dry and sustain damage - if it is too high the pond will overflow.)

Eagle Technology provides an easy solution for such installations. The application modules are equipped with screw terminals for quick installation. The only wiring that needs to be done is the actual connections from the application module to the switchgear. In this case the connection from the solid-state relay board to the contactor or valve. The modules can also be DIN rail-mounted, which is standard for any industrial application. The single biggest advantage is that the installation is easy to repeat and to do multiple installations. No soldering or extra connector blocks are needed. It is quick and simple to install. Eagle Technology provides all interconnection cables as standard.

The control software was also developed by Eagle Technology and includes modes for the realtime clock, the sequential mode and a manual mode. A full event logger is included which logs all events like application shutdown, start-up, level alarms and power failures. It also has a scheduler to automatically go to sleep at a preset time and to be activated at a preset time. The software loads its sequences from a database, which makes developing new sequences easy. Another feature, which is very important, is that in an event of sudden power loss, the computer will reboot. The software will load on start-up and detect that it was not shutdown properly. It will simply reload the last sequence before the power failure and continue as before. This is very important for process control systems to have some sort of auto recovery feature. The manual mode is mostly used for debugging and faultfinding, either locating faulty hardware or faulty wiring. To secure the control station, the application can also be locked by an operator.

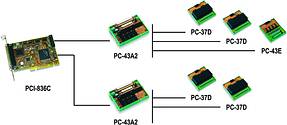

Eagle Technology also supplied the PC-based system, which included a PCI digital I/O board (PCI-836C), a docking board (PC43A2), eight channel solid state relay boards (PC-37D) and an eight channel optically isolated input board, (PC-43E). The diagram shows a typical configuration having the capability to switch 32 channels, each 220 V a.c. via 2 A, solid-state relays and monitor eight analog voltage inputs (0 to 32 V d.c.).

The company stocks a wide range of process control products and accessories. This includes PC based plug-in boards for analog inputs, analog outputs, counters, timers and digital I/O. There are accessories to help ease installation and complement the PC based products. Full data acquisition systems implemented on industrial PC platforms are also on offer.

Henry Hugo, EagleTechnology

021 423 4943

© Technews Publishing (Pty) Ltd | All Rights Reserved