Gas analysis has traditionally concentrated on emission measurements which primarily entail extraction methods. The current industrial trend, measuring gas concentration in order to control processes, involves completely new analysing technologies.

AltOptronic makes use of a measuring method that makes it possible to obtain in situ measurements directly from the heart of a process. A method that does not affect the process itself and that provides split-second responses and highly accurate results. A method that is automatically self-calibrating and practically maintenance-free.

The measurement method is based on a patented concept that makes it possible to take measurements in extreme environments. There are no sensitive electronics located at hazardous measuring points and yet, this method has the ability to read the exact gas concentration despite high temperatures, powerful magnetic fields and explosive environments.

Use is made of a laser diode technique in which the laser light is specifically adapted to the gas being measured, thereby eliminating interference from other gases. The patented signal-reading technique allows measurements to be made in environments containing heavy and dynamic dust concentrations.

The design of the analyser is intended to provide new possibilities for process control and emission measurement. A number of advantages are gained from the ability to read measurement signals during the early part of a process phase and in realtime from within an incineration or other relevant process.

The advantages vary depending on the process in question. This unique method works to increased efficiency and lower process maintenance costs, which in turn result in economic rewards and reduced impact on the environment.

Chemical and petrochemical industries

The LDS 3000 is certified according to the EEx ia IIB T6 and is well suited for a number of applications.

It is possible to obtain exact measurement signals directly from the heart of the most adverse incineration environments. The sensors exist in several different designs depending on the application. The most common is the crossduct, where a mean value of the gas concentration is obtained from the measured path. In other words, there is not only one measurement point.

Since the sensors do not contain any sensitive electronics, they fulfil their function even in extremely difficult environments involving high temperatures and high magnetic fields. They are simple to install and require low maintenance. At the same time, they fulfil the standards of IP65 and one model is certified EEx ia IIBT6.

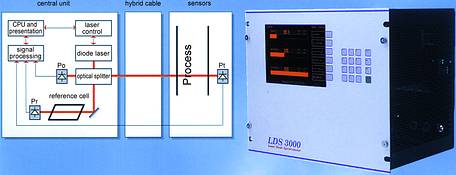

The laser unit is placed inside the central unit, from where the laser light is conveyed to the measuring point via optical filter. The LDS 3000 can simultaneously handle measurements in up to three different points. The laser light is therefore divided into separated beams. After the light has passed through the measuring path, the resulting measurement signals are returned to the central unit as optical signals. The signals are then compared with the equivalent signal from a reference cell built into the central unit that contains a known concentration of the gas to be measured. By comparing the height of the absorption lines, the gas concentration in the process can be calculated.

In other words, the LDS 3000 is continuously self-calibrating. Since it uses a laser diode that is tuned to a single absorption line corresponding to the gas being measured, the signal is free of interference. With the patented signal control, the measurements are not affected by any dust presence, even when dust levels vary significantly.

The precision is 2% of the reading. The resolution depends on gas concentration and is in direct linear relation to the optical measuring path.

| Tel: | +27 12 665 0317 |

| Email: | [email protected] |

| www: | www.spero.co.za |

| Articles: | More information and articles about Spero Sensors & Instrumentation |

© Technews Publishing (Pty) Ltd | All Rights Reserved