In Part 2, (SA Instrumentation and Control February 2010), we saw the different information needs of business and production processes and how they could be reconciled through existing application framework ‘filters’ and the use of standards such as ISA-95. Having got the technology hurdle out of the way, it is time to consider the human aspect of enterprise integration in respect of business IT and shop floor IT.

Traditionally, IT managers have paid as much attention to the realtime complexities of the shop floor as the rest of us paid to root canal. As the shop floor got itself better organised and historians became the repositories of vast quantities of mission-critical information, CEOs started to wonder why they were running two information departments. And the instrumentation engineer started to wonder why he was beginning to understand what his IT colleague was talking about.

In the 1960s and ’70s, we had data processing managers running data processing departments. Those were names given to a breed of individuals who understood computers while everyone else stood around in awe – Stonehenge, high priests, peasants – same sort of thing. Data processing personnel were not only required to look after the roomfuls of hardware but were also responsible for developing the software that would allow the company to run its business processes more effectively. Today, almost everyone can use a computer, and we have more commercially available software than we can handle. No more mystery there, but the complexities of network optimisation, security and so on ensured that the high priests would remain gainfully employed in the role of information technology experts.

The instrumentation engineer’s job changed the instant someone else wanted to know what he did within the grander scheme of things. They suddenly realised that optimising P&IDs had no meaning if it did not help the company achieve its business objectives. In order to contribute to this, they needed to change their role from instrumentation engineer to information provider. For the sake of efficiency, profitability and competitiveness, it became necessary to take a more formal approach towards the gathering and compilation of realtime information from the shop floor and to reconcile it with the traditional business systems. In this way MES (manufacturing execution systems) became a reality.

Today, we have a situation where realtime data repositories can eclipse those of business IT systems in sheer magnitude, scope and criticality. The shop floor now has disaster recovery and change management solutions to automatically back-up, compare and diagnose releases of HMI, PLC and robotic software. By definition, the instrumentation engineer has become a high priest of data processing because he knows things other people do not. This has angered the ‘traditional’ high priests of data processing because they are no longer in complete control of the company’s information needs. Yet, these same high priests are not comfortable working in the realtime environment where data is needed on a millisecond time scale.

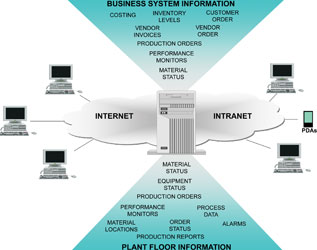

Ergo, in today’s reality, we have companies with what amounts to two IT departments – one in charge of making the money (production) and the other in charge of managing it (traditional business IT). The information pipeline that connects the two can be as thick or as thin as needed and the connectivity at either end of this pipeline is defined by international standards like ISA-95.

So, who and how does an enterprise-wide manufacturing IT affect?

Two IT departments may seem like a bad idea but, because of their totally different operating environments, there may be no other way – at least at the technical level. However, information is what counts and dictates the necessity for seamless access at all levels. Unifying a company’s information requirements into a seamless asset is going to affect at least four groups of people within the organisation:

The instrumentation engineers

Being an information supplier in charge of, often, more than half of the company’s total information assets, rarely formed part of their job description. While programming computers can be fun (?) diagnosing processes and improving them is often a lot more rewarding. So, the instrumentation engineers should be allowed to exercise their process optimisation skills and they should consider getting help (wrt data processing) from the traditional IT department who are well versed in the management of information and its infrastructure.

The production managers

Find themselves at the crossroads of the two IT blocks and at the crucial point where business needs must be reconciled with production reality. They need access to ERP as well as shop floor information in order to effectively manage production, maintenance, quality and inventory processes. In other words, they need all the help they can get from all the information sources.

The IT managers

While millisecond response times and realtime diagnostic procedures may not be what you are used to, they are not your problem. Let the people who know about these things handle them. Instead, you bring a wealth of knowledge to the management of information and you should lend your instrumentation colleague a hand.

The CEOs

Because of their vastly different functions, two information repositories are probably inevitable because they each have quite different operating specifications. This is not a duplication of assets but rather a step closer to having a unification of information assets geared to providing factual information, cause and effect scenarios and performance measurement facilities that will keep your finger on the pulse of your organisation.

As for solution providers, they too are taking a more holistic approach to information delivery:

Scada solution vendors

Today, most scada solution suppliers no longer consider that their products operate outside the ambit of business information provision. While pipelines to scada data are next to useless, connectivity to scada information is useful. But, data is transformed into information by applications, and, since there is more than one application vendor on the planet, they are going to need to conform more and more to information exchange standards.

MES solution vendors

They have always had to recognise the realities of process control and ERP at opposite ends of the spectrum of information they must supply. The need for compatibility between the two has increased greatly over the last few years.

ERP solution vendors

They recognise the importance that MES and scada play to close their production, maintenance and other loops and are actively working at making connection to their systems easier and seamless.

A unifying suggestion

One solution that has been tried and seems to work well for reconciling the differences between the two IT departments, is to create the position of CIO (chief information officer) to whom both the business IT manager and the process control engineer in charge of shop floor IT report. The need for enterprise-wide IT is not only obvious but a necessity, so there is no point in avoiding the issue of merging these different disciplines into a collaborative entity.

With this unified information structure chief executives and management should also start getting used to the idea of change, because this new approach will revolutionise accounting and enterprise-wide costing, performance management and personnel recognition.

In Part 4, we see the vital role that manufacturing enterprise solution (manufacturing execution systems) play at the core of the enterprise’s information network.

For more information contact Deon van Aardt, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved