Shell Eastern Petroleum (SEPL) recently completed its ethylene cracker complex (ECC) as part of its ‘Houdini’ project in Singapore.

One of the key features of the project is that this is a deployment in an oil & gas environment, where wireless technology is being used to get secure mobile access to Process Control systems. Shell wanted to get mobile access to all process data via WLAN at defined places in the refinery to drive efficiencies. Another important consideration was that all relevant parts of the solution had to be certified to comply with ATEX/IEC60079.

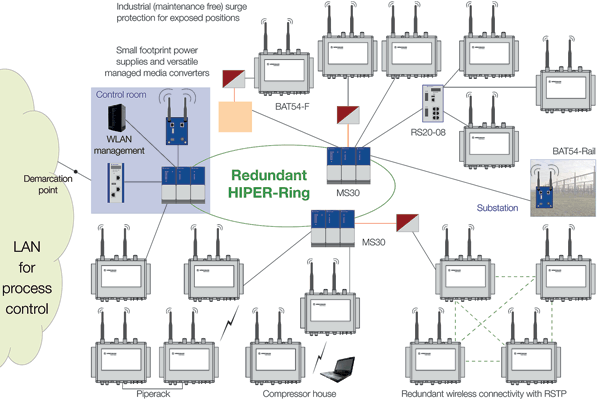

Working closely with main automation contractor Yokogawa, the Belden team took on the design and build of a complete WLAN solution, consisting of a wireless distribution system incorporating 90 Hirschmann BAT54-F X2 access points for the ECC and multiple antennas, linked across a redundant fibre ring backbone.

Pioneering the technology

The application required a full range of Hirschmann WLAN products including outdoor access points together with accessories, antennas, surge arrestors, managed switches, media converters and Industrial HiVision. For enhanced security, the Eagle firewall was used at the demarcation point to the process LAN. To build the backbone, Belden’s Profinet copper and fibre optic cables, as well as Lumberg Automation Ethernet M12 connectors for all Ethernet devices. At locations where wired LAN access was difficult, connectivity was established by applying cost effective and easy to manage wireless point to point links.

A specific challenge for Belden was to provide all equipment with proper ATEX/IEC60079 certification for the challenging conditions found on this project. Olaf Schilperoort, product manager for Hirschmann wireless devices says, “Shell knew what they wanted and we quickly found a common level of understanding. We also saw the great chance to become pioneer for WLAN solutions in these harsh environments and so we developed a new product according to the specifications set out by Shell.”

Delivering the solution

The Belden project team planned the system at the Belden Competence Centre and it was here that the first factory acceptance test (FAT) involving the complete system was conducted. These comprehensive tests included hardware, software, documentation and the overall system functionality including roaming capability.

The test proved successful and with Shell’s approval, the entire set-up was moved to Singapore for the integrated FAT to ensure that it functioned seamlessly as part of Yokogawa´s overall control system – again the test proved successful.

Peter Beerepoot, responsible for instrumentation process control for the entire Houdini project says, “Our initial thoughts during the front end engineering and design phase, was that wireless would give us a number of key benefits. So we considered substitution of local panels, which we believed would bring us advantages in terms of cost reduction and increased efficiency. However, it is always difficult to test a new system in an existing plant. Here we were given the opportunity to develop a complete infrastructure. Today, we not only have the proof that the Belden system works, but because the coverage is better than we originally expected, we are now looking at options to maximise our usage of the system even further. The Belden Team delivered excellent work and proved to be a reliable partner throughout the project.”

Conclusion

By successfully delivering this project, Belden has demonstrated that it offers a complete solution for scalable, redundant LAN and WLAN architectures for the process industry. In this case, the solution encompassed an entire WLAN system with ATEX certification and full project management and service that has provided the customer with both improved operational efficiency and cost reductions. Belden will continue to work on this project to deliver service programs and further expand the network for better WLAN coverage and new services like Ex zone certified wireless video for safety and surveillance applications.

For more information, contact Cliff Nel, IAC, +27 (0)12 657 3600, [email protected],

| Tel: | +27 12 657 3600 |

| Email: | [email protected] |

| www: | www.iacontrol.co.za |

| Articles: | More information and articles about Industrial Automation & Control (IAC) |

© Technews Publishing (Pty) Ltd | All Rights Reserved