Smart Press Kit from Bosch Rexroth

October 2019

System Integration & Control Systems Design

Bosch Rexroth is setting new standards for fast and efficient pressing and joining applications with its innovative new modular Smart Press Kit. Designed to meet future industrial requirements by providing a complete mechatronic package across a wide range of pressing and joining applications, the kit functions according to the Plug and Produce principle, and will be supplied in sub-Saharan Africa through Tectra Automation.

Industry requirements and processes are shifting away from individual products to complete system kits. In the factory of the future, machines, production lines and storage systems will collaborate within a network composed of cyber-physical systems (CPS) that will be capable of autonomously exchanging information, triggering actions and controlling one another. The Smart Press Kit is an innovative solution on the road to Smart Factory. It delivers swift, easy commissioning with automatic configuration.

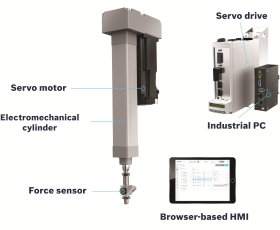

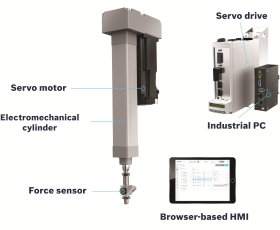

The modular kit consists of synchronised hardware and software components: electromechanical cylinder and power sensor, servo motor, drive controller, industrial PC and browser-based HMI software. Pre-selected mechanical, electrical and software components are combined in various kits for forces from 2 to 30 kN.

Automatic parameterisation of the servo drive, pre-installed operating software and a minimal number of interfaces, the kit simplifies configuration and commissioning, maximises transparency, reduces downtime and increases productivity, saving up to 95% engineering time. The new software with an intuitive, modern design is Industry 4.0 capable thanks to a connection via OPC-UA, and no programming knowledge is required.

Ideal for applications where simplicity and rapid commissioning are all important criteria, the Smart Press Kit has wide application across industry. It can be used for assembly, joining, forming and testing applications. “The Smart Press Kit can be used as a standalone solution or as an integrated solution,” concludes Tectra Automation product manager Julie van den berg. “It is the perfect addition to complement our offerings across industrial and factory automation applications in sub-Saharan Africa.”

Further reading:

Modernising Vertical Filter Press Machines with Future-Focused Control Systems

System Integration & Control Systems Design

Project and Industry

Pressure Filter Specialists approached us to modernise vertical filter press machines for the Minerals and Metals industry. The goal was to improve reliability, reduce downtime,

...

Read more...

Project & industry

System Integration & Control Systems Design

Project and Industry

This project involved delivering a complete electrical, instrumentation, and automation solution for a new OEM drum-twister machine, replacing an ageing unit in a major cabling production

...

Read more...

It’s a risky business not to challenge standard language

System Integration & Control Systems Design

On the surface, contracts all look alike. Once you’ve seen one, you’ve seen them all, or so it seems. Maybe so, but hidden within the standard language can be language that shifts the other party’s risk to you.

Read more...

Containerised Electrical & Control System Powers Paste Plant in Botswana

System Integration & Control Systems Design

Delivering a complete, containerized solution for a mine’s paste plant in Botswana, this project stands as a model of modern EC&I execution — integrating electrical, control, and automation systems into

...

Read more...

Control system upgrade: Smelting

SAM Systems Automation & Management

System Integration & Control Systems Design

Systems Automation & Management recently completed a major control system upgrade in the smelting industry. The project was delivered on budget and achieved a positive ROI for the client.

Read more...

Gottwald drives upgrade: Ports and harbours

Abacus Automation

System Integration & Control Systems Design

In the ports and harbours sector, Abacus Automation completed a significant modernisation of a Gottwald crane, improving both operational reliability and serviceability.

Read more...

Mining industry upgrade: From ageing systems to maximum capacity

System Integration & Control Systems Design

Iritron recently undertook a major upgrade in the mining sector, focusing on washing and screening plants, jigs, thickeners, tailings, water systems, conveyors and reclaimers.

Read more...

Agogo Integrated West Hub Project: FPSO/subsea offshore Angola

Moore Process Controls

System Integration & Control Systems Design

The Agogo Integrated West Hub project represents a historic milestone in the FPSO and subsea industry, achieving first oil offshore of Angola. This project is the first FPSO deployment since ANPG’s establishment in 2019, and the first major project for Azule Energy since 2022.

Read more...

Integrated Robotics and Control Systems Deliver 45% Production Boost at Aquazania Waters Project and Industry

Process Dynamics

System Integration & Control Systems Design

Project and Industry Process Dynamics designed and commissioned a state-of-the-art Reverse Osmosis

(RO) water purification and automated bottle filling plant for Aquazania Waters in Linbro Park, Johannesburg.

...

Read more...

Project and Industry

System Integration & Control Systems Design

The Sicomp Control System Upgrade focused on modernising a 1985 power generation control system with more than 3 000 I/O points. The plant faced increasing system failures and risk to operational continuity,

...

Read more...