Yokogawa has announced that it has added two new solutions to the Opre analyser family with the development of the FLXA402 4-wire liquid analyser and the SA11 smart adaptor. These two new liquid analysis products will be offered as part of the Sencom 4.0 series. It is expected that they will help to improve the efficiency of calibration and other maintenance tasks, and facilitate the flexible design and operation of liquid analysis data monitoring systems.

Liquid analysers consist of a sensor and a transmitter with a data conversion function, and are used to monitor items such as the quality of raw materials and finished products, and water quality in the wastewater treatment process. They are utilised in a wide range of industries including power, water supply, municipal and industrial wastewater treatment, semiconductors, foods, pharmaceuticals, iron and steel, pulp and paper, oil, petrochemicals and chemicals. The two basic types of transmitters are 4-wire devices with separate cables for power supply and output and 2-wire devices that use the same cable for power supply and output, and Yokogawa supplies both. Yokogawa’s 4-wire transmitters are typically used for specific applications such as pH measurement, and its FLXA21 and FLXA202 2-wire transmitters can flexibly accommodate multiple sensors of the four basic types: pH/ORP, conductivity, inductive conductivity and dissolved oxygen. Although the FLXA402 is a 4-wire system, it can connect to multiple sensors, perform diagnostics, and communicate digitally with host systems.

In liquid analyser applications, there is a need for data monitoring systems consisting of integrated sensors and transmitters that are capable of transmitting data directly to a control system, recorder, indicator, or a handheld device such as a tablet. Although such integrated devices are able to store data that is needed for calibration and other maintenance tasks, the entire unit needs to be replaced when sensor damage or fouling occurs due to exposure to liquids. To reduce maintenance costs, Yokogawa has developed the SA11 smart adaptor, which also functions as a transmitter. As only the sensor needs to be replaced, this significantly reduces maintenance costs and eliminates waste.

Product features

The new products are the FLXA402 4-wire liquid analyser, SA11 SENCOM smart adaptor, and pH and ORP sensors that are dedicated for use with the SA11. There is also a new peripheral device: the BA11 junction box.

FLXA402 4-wire liquid analyser

Reduced cost and footprint: the instrument can work with existing analog sensors (pH/ORP, conductivity, inductive conductivity, and dissolved oxygen), optical dissolved oxygen sensors, and the SA11 Sencom smart adaptor and its dedicated sensors. By using it in combination with the adaptor and the BA11 junction box, it is possible to connect up to five sensors, reducing both system cost and footprint. For the transfer of diagnostic data and other device information to a host system, the device supports the HART and Modbus protocols. This solution also facilitates connection to the cloud and an IIoT environment for improved field maintenance.

SA11 SENCOM smart adaptor

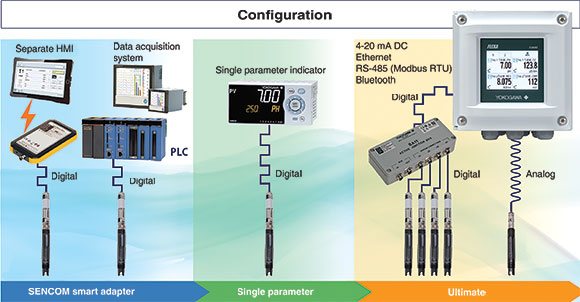

Simple but flexible system configuration: the adaptor has functions for data conversion, transmission, calibration, and diagnosis, and is intended for use with dedicated sensors. It supports the Modbus communications protocol. Using the adaptor, it is easy to set up a system that can perform data monitoring, calibration, setting, and adjustment.

Improved maintenance efficiency

As the SA11 is able to store sensor calibration data and other types of digital information, it can be transferred to a laboratory or some other location that is safer and has better working conditions. This reduces the amount of maintenance work that needs to be performed in the field and helps to ensure that the device stays properly calibrated, thus reducing downtime.

For more information contact Eugene Podde, Yokogawa South Africa, +27 11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved