The company that manufactures concentrate for Coca-Cola’s bottling plants in Africa was unaware of exactly where the plant’s energy was being consumed and what the power usage was on a daily basis. A corporate directive was initiated to reduce energy consumption by 20% in 12 months.

Problem definition

The existing systems could not answer the user requirement satisfactorily. “Only the two main electricity incomers were measured, there were no sub-area, breaker, air, water and steam measurements being added for context,” says Gordon Schoombie, director of operations, Systems Anywhere Coastal. “The client required this critical information in order to understand how the energy was being consumed and what could be done to reduce the usage.”

Conco Swaziland wanted complete and instantaneous access to information that would allow it to determine the specific amounts of power associated with each section of the plant, the fluctuations in usage at specific times of the day and how much power was used during different processes. “With this information available, it would be possible to institute the appropriate energy saving measures needed to reduce maximum demand,” explains Schoombie.

“The client requested that the automation and control of the cold rooms ensured they ran cost efficiently but at the correct temperatures, and that the dust extraction systems were run only during scheduled work hours. Up to date information via the Internet was required on mobile devices that provided an in depth analysis of power in the phases and other Web based reports.”

Managing change and implementing the solution

The entire company was involved in the process of change, but most influential were executive management and technical services. “The client had to be convinced to make the initial investment into the project, as there was a misconception that the control system could allow the factory to run effortlessly at the push of a button. In reality, it must be continuously analysed and accessed in order to provide the information that enables better decision making,” says Paul Kotze, lead software engineer on the project.

Initially, there was suspicion associated with the results obtained during the commissioning phase, but these were validated by the main utilities supplier and when the error margin was down to less than 1%, management and the other stakeholders bought into the system enthusiastically.

The project was awarded at the start of October 2011 and commissioned in mid-December 2012. “During this time, the scope of the project was clarified with URS documents, the development work was implemented and final project documentation in terms of electrical drawings and other relevant paperwork was completed,” explains Kotze.

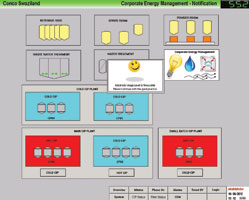

Systems Anywhere Coastal configured, developed, installed and commissioned the Wonderware Corporate Energy Management, Mobile Reporting, Historian, Historian Client and System Platform solutions; supplied and installed Microsoft SQL server and SQL server reporting services systems; configured, installed and commissioned the Software Toolbox (Beckhoff I/O driver) and a Beckhoff PLC with power modules and remote BK units and configured and commissioned Topserver.

Requirements included web-based reporting on a monthly, weekly and daily basis; real-time trending of demand and kWh using analysis tools and mobile reporting for iPad and smartphones on maximum demand and cost/usage. Systems Anywhere Coastal will provide the client with ongoing advice on how to maximise the benefits of the system.

Systems Anywhere Coastal faced logistical challenges due to the fact that the plant is located cross border. “In addition, this new release of Wonderware CEM modules with additional functionality had not been used by us in a production environment before, so we had to bring our technical team up to speed quickly,” says Kotze.

The client feedback has been very positive as Systems Anywhere Coastal has created a strategic and tactical energy monitoring and control solution that will save money and reduce the client’s carbon footprint. “With the benefit of hindsight we could have created a better understanding between the client and ourselves of the eventual solution implementation; it is often difficult to get this perspective from proposals and user documentation. A thin slice (pilot project) type implementation could be used as a starting point and then one could redefine the project,” says Schoombie.

“With the cutting edge technology solution provided by this professional consortium of Systems Anywhere Coastal, Beckhoff and Invensys CEM, Conco is guaranteed a sustainable carbon footprint for the next ten years and will be able to convert its previously fixed energy costs into a well managed variable cost of production,” concludes Conco process engineer, Wiseman Magagula.

For more information contact Gordon Schoombie +27 (0)21 911 3384, [email protected] or Andre Vuilleumier, +27 (0)11 024 5491, [email protected], www.systemsanywhere.com

© Technews Publishing (Pty) Ltd | All Rights Reserved