All aggregates and bulk solids contain an amount of water. In addition to the quality of the final product, moisture also determines the weight and the price. The IMKO probe portfolio from Endress+Hauser presents a new generation of moisture sensors, suitable for use in a variety of industries.

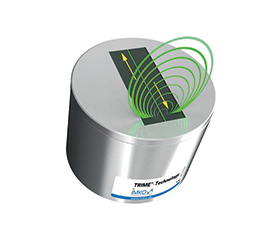

The guided radar wave (in green in the image) propagates at approximately the speed of light. The sensor measures the material layer by layer discoidally and transverse to the sensor surface, as is familiar from a computer tomograph, for example.

This method results in a sensor with an exactly defined measurement field, which can measure without errors even in the event of fluctuating fine grains or varying grain size. By measuring transverse to the sensor surface, the mechanical condition of the sensor surface does not represent a disturbance variable, i.e., the recurring and unavoidable wear of the sensor surface does not falsify the measured value.

The defined measurement field also enables accurate measurement for applications in which the material coverage is too low or fluctuates. This results in a high degree of flexibility in terms of mechanical integration in the application.

Drying bulk solids in belt dryers

When drying bulk solids with belt dryers, an air-permeable belt is filled with the product to be dried. The height of the bulk solids on the belt and the dwell time in the dryer are defined based on the product type and properties, and the water volume to be removed. By adjusting the dwell time to the mean value, it is possible to compensate for varying moisture content. This is necessary in the production of wood pellets, for example, because the quality is no longer guaranteed if the material is excessively dry, and operating times are put at risk if the material is too moist.

Drying of bulk solids in vertical dryers

When grain is harvested, it usually contains excess water. If the grain is stored in a silo, this excess water would cause mould to form immediately, resulting in the total loss of the product. Therefore, all common grain types are dried before being stored in a silo, usually using a vertical dryer with product passing through it once (continuous dryer). The input moisture is measured to determine the water quantity to be removed, and the dwell time or throughput rate is controlled based on the known dryer performance. This not only ensures that the product does not go mouldy later in the silo, but also that energy is not wasted by over-drying the product.

The IMKO portfolio allows users to choose a suitable moisture sensor design for any application, always taking into account the framework conditions, such as moisture range, electrical conductivity, wear and mechanical installation.

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved