Commonly known as ‘the smile maker’, Dairymaid’s ice cream has been a favourite in many South African households for the past three decades. Keeping the factory running and ensuring the quality of the ice cream remains at an exemplary level is critical to the brand’s reputation.

PCS Global was the first choice to upgrade the Clayville, Gauteng, factory’s control system. Wonder Phakathi, control systems engineer at PCS Global, explains: “Two years ago, Dairymaid contacted us on Christmas Eve with a downtime problem on the production line. We assisted them and the problem was quickly resolved. This resulted in PCS subsequently providing a consulting service and, during a complete system audit, we identified a number of key risk areas that were affecting productivity.”

Centralisation of systems

The existing system at the Dairymaid production facility had a number of issues which needed to be addressed to ensure minimised downtime and enhanced productivity. Phakathi says that the outdated Wonderware system licences posed a risk as they were based on an old, legacy operating system which was no longer supported by Microsoft. In addition, a number of redundant licences were not being used.

“Lack of centralisation of systems was another pressing problem,” explains Phakathi. “Outdated infrastructure and non user-friendly interfaces meant that not only was the system unstable, but it was also difficult to isolate problems efficiently. This ultimately led to losses, so in order to ensure that the company was not plagued by unnecessary downtime, we needed to upgrade the system,”

The upgrade process firstly entailed a complete restructuring of the control systems architecture. The primary intention was to eliminate standalone systems and create a centralised data repository. The firmware and the hardware were both outdated, making the system cumbersome and ineffective. The look and feel of the scada was updated and optimised to make it easy for the operators to fault-find.

“The Wonderware packages were in fact two versions older than current firmware models, leading to minimal support available for them,” says Phakathi. “Similarly, the hardware was an outdated version going back to 2008, making it extremely slow and prone to excessive downtime.”

System upgrade

According to Phakathi, the biggest challenge PCS faced was in retrieving the data from the legacy system: “We encountered a large number of corrupted data backups, so it took us much longer than expected to update the system. In addition, we had to perform the upgrades while production was underway, in order to further minimise downtime. The project was a learning curve for all and has highlighted the problems encountered when regular firmware, software and hardware updates are not performed.”

PCS upgraded the control system to a virtualised server which allocates functions according to the new architecture. The development environment, which includes Wonderware System Platform and Historian (2017 versions), was centralised for ease of management and control.

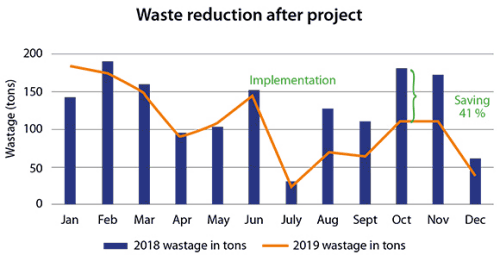

The project started in April 2019 and commissioning and handover began in early November. “We have added on further elements as the project evolved and we are currently still working with the Dairymaid team to ensure that the system is optimised,” says Phakathi. “The expanded system is now completely stabilised with added functionality and a reduction in downtime of an admirable 41%. The project was rapidly and efficiently deployed, resulting in a return on investment within two months. The success of this project has resulted in Dairymaid’s management initiating audits on other areas within their operations and the cost savings they have realised from the reduced downtime is now being allocated to further optimisation.”

PCS Global provided training on the new system and provided the operators with an SOP manual and insights on how to leverage the benefits of mobile apps to provide a further, remote level of monitoring and control. The new system is highly intuitive, making it easy to navigate and produce beneficial reports. Phakathi concludes that the feedback that PCS has received is that the site coordinator and operators are now more inclined to use the software, resulting in a more productive environment.

| Tel: | +27 11 466 4172 |

| Email: | [email protected] |

| www: | www.pcsglobal.com |

| Articles: | More information and articles about PCS Global |

© Technews Publishing (Pty) Ltd | All Rights Reserved