Operating safely

September 2009

Fieldbus & Industrial Networking

Fibre-optic fieldbus systems in oil production.

Hirschmann networks recently developed oilfields in the United Arab Emirates with highly available fibre-optic fieldbuses.

Production has recently started at two new oilfields 50 km southwest of Abu Dhabi city, Rumaitha in the countries interior and Al Dabb’iya on the coast. The daily production capacity of the fields is about 100 000 barrels. The facilities for producing, storing and metering the crude oil have been in operation since late 2005. Operating safety is paramount here, so the process control system has been designed with full redundancy, and data is transmitted between the controllers and the remote I/O stations via fail-safe, redundant optical fibres. The danger of explosion that is inherent in such facilities presents a particular challenge. This challenge must be met with ATEX approved devices that are also capable of withstanding high ambient temperatures.

Project details

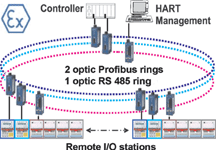

The process control is designed as a redundant system to specifically meet the customer’s demand for high process data availability. The process control units constructed by Honeywell provide a primary and a secondary Profibus DP interface with the remote I/O stations. HART information is recorded via an independent service bus using an RS485 interface. Optical cables and redundant optical rings ensure an exceptionally high level of operating safety. The cabinets, installed in explosion protection zone 2, include devices for properly isolating the intrinsically safe signals that are primarily used here for transmitting to zone 1 and zone 0. The power supplies for the remote I/O stations are designed redundantly. The cabinets have been engineered to prevent heat accumulation and they are also equipped with solar protection means. Otherwise, it would not be possible to keep the electronic components in the cabinet sufficiently cool in desert conditions.

Project parameters

* Profibus DP and HART communication.

* 15 km transmission length.

* 2600 process signals.

* 72 remote I/O stations.

* 176 OZD Profi 12M G12.

* 26 OZD Profi 12M G12-1300.

* 88 OZD 485 G12.

* 13 OZD 485 G12-1300.

Requirements

* High availability of the process control system.

* 85°C solar temperature.

* 52°C air temperature.

* 95% maximum air humidity.

* Explosion protection zones 2 and 1.

Solution

* Redundant control stations with two Profibus interfaces.

* Redundant communication via optical Profibus DP rings.

* Communication with HART management system.

* Switch cabinet designed for high operating temperature.

* Devices ATEX-approved.

Why Hirschmann

* Fibre-optic converter for Profibus DP.

* Fibre-optic converter for HART via RS485.

* Designs for long and medium segments.

* Redundancy with optical rings.

* ATEX approvals received.

For more information contact Profitek, +27 (0)12 664 4998, [email protected], www.profiteksa.com

Further reading:

Introduction to Part 2 loop signatures and process transfer functions

Fieldbus & Industrial Networking

The previous series of loop signature articles dealt with the basics of control loop optimisation, and concentrated on troubleshooting and ‘SWAG’ tuning of simple processes. In this new series, consideration will be given to dealing practically with more difficult issues like interactive processes, and with processes with much more complex dynamics.

Read more...

Siemens sets new standards in drive technology

Fieldbus & Industrial Networking

Siemens is setting new standards in industrial drive technology with the launch of its new high-performance drive system, Sinamics S220. This offers a seamless and innovative drive system with comprehensive simulation and analysis capabilities and advanced connectivity features that enable full integration into digital work processes.

Read more...

PC-based control in the plastics industry

Beckhoff Automation

Fieldbus & Industrial Networking

Nissei Plastic, an injection moulding machine manufacturer based in Japan is implementing a worldwide tend towards open automation systems from experienced specialists using PC and EtherCAT-based control technology from Beckhoff.

Read more...

Loop Signature 31: Non-linearity in control loops (Part 2)

Michael Brown Control Engineering

Fieldbus & Industrial Networking

This article is a continuation of Loop Signature 30 published in the last issue in this series, exploring reasons for non-linearities which may be encountered in feedback control loops

Read more...

PC-based control optimises robotic parts handling on plastics machinery

Beckhoff Automation

Editor's Choice Fieldbus & Industrial Networking

NEO is a cartesian robot developed by INAUTOM Robótica in Portugal for parts removal on plastics machinery. Its aim is to increase system productivity. NAUTOM Robótica has entered into a strategic partnership with Bresimar Automação to increase the working speed of the cartesian robots using advanced control and motion solutions from Beckhoff. The result is a comprehensive, future-proof automation solution for its entire family of cartesian robots.

Read more...

PC-based control for flat wire motors for electric vehicles

Beckhoff Automation

Fieldbus & Industrial Networking

Special machine manufacturer, ruhlamat Huarui Automation Technologies unveiled the second generation of its mass production line for flexible stators with bar winding. This enables extremely short production cycle and line changeover times, supported by PC- and EtherCAT-based control technology from Beckhoff.

Read more...

Case History 200: The final case history – desuperheater control problem.

Michael Brown Control Engineering

Editor's Choice Fieldbus & Industrial Networking

For this final article I have chosen to relate a problem that existed in a desuperheater temperature control on a boiler in a petrochemical refinery.

Read more...

PC-based control technology in additive manufacturing

Beckhoff Automation

Editor's Choice Fieldbus & Industrial Networking

As an open control platform, PC-based control supports different engineering approaches, including low-code programming. The machine builder, Additive Industries uses this to create the code for the TwinCAT runtime of its 3D printers.

Read more...

Suppression and safety solutions for fire and gas in mission-critical industries

Fieldbus & Industrial Networking

By representing world-leading brands and focusing on fully integrated, certified systems, HMA South Africa is positioning itself as a trusted partner in fire detection, suppression and explosion-proof safety solutions across the continent.

Read more...

Integrating fire alarm systems into building management systems

Beckhoff Automation

Fieldbus & Industrial Networking

Fire alarm systems work independently of the building automation system. Schrack Seconet has developed a flexible gateway using ultra-compact industrial PCs and TwinCAT from Beckhoff, which can be used to flexibly convert a customer-specific communication protocol to a wide range of transmission standards.

Read more...