Eclipse recently updated a successful system for a customer using the eXtended Transport System (XTS) to assemble automotive transmission pumps. While increasing functional capabilities, the custom solution needed to minimise the footprint. “When we proposed the system, they asked us to make it 25% smaller,” says Jeff Werner, general manager for Eclipse.

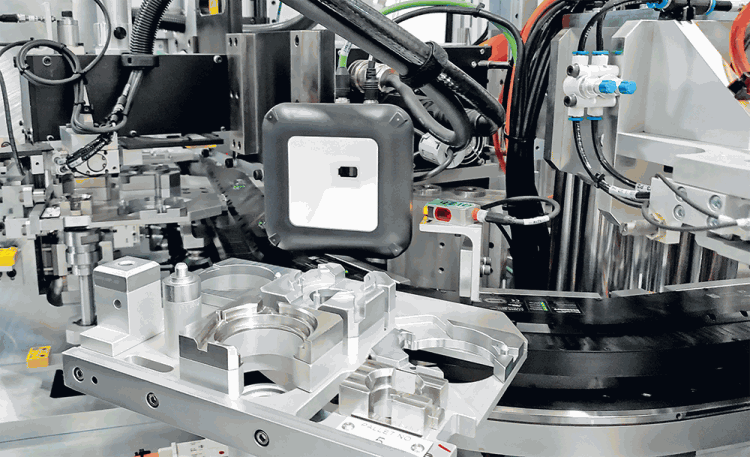

The XTS-based assembly line features four separate cells with more than 50 stations for pressing, soldering, screwdriving, flatness checks, dispensing, plasma treatment, leak testing and inspection. Many stations require precise synchronisation to robots. In the first three machine cells, operators place the pumps on pallets attached to XTS movers. The carefully calculated pitch of the pallets enables micron-level positioning. When all assembly processes are complete, the operator moves the pump to the next cell. At the fourth cell a robot lifts the completed pump in front of two GigE cameras for a final vision inspection, then places it on a conveyor for outfeed.

“XTS transitions products from station to station quickly and accurately, and if there’s an issue with a part we can bypass other stations and simply remove it,” Werner explains. “We grouped multiple processes into a single station, which helped us further decrease footprint. It was the most condensed automation system I’ve ever seen.”

The first Eclipse assembly machine exceeded expectations and is still in use today. Then the automotive supplier requested a second machine with a new challenge. It would need to make a second pump on the same system. The pumps were different sizes and for different vehicle makes. Also some assembly steps happened in different orders for the two pumps. To maintain high throughput, the system could not afford the downtime to purge one pump type and then perform a lengthy changeover.

Working with the Beckhoff team, Eclipse created a new concept relying on the fast cycle times of EtherCAT and the flexibility of XTS. “The system allows operators to quickly release and replace the pallet with a second type. This new pallet indexes forward and its position is measured to determine an offset. We apply those offsets to each pallet and make sure that components and parts line up exactly for the processes,” Werner explains. “Also, because each mover appears as an individual motion axis, they are not linked as in traditional designs. They can freely move workpieces around the track to specific process steps as needed, even if the order is different between the two pumps.”

In addition to the XTS systems, the assembly line relied on other EtherCAT and PC-based automation technologies from Beckhoff. The cells featured an IPC to control their XTS track and peripheral devices. The IPCs communicated via EtherNet/IP to a secondary machine controller that controlled other portions of the line. Real-time EtherCAT synchronisation with robotics and servo components allowed the engineers to perform interpolated motion for different dispense processes such as applying adhesive in intricate patterns. To make this advanced functionality possible, TwinCAT 3 automation software was critical. The universal engineering and runtime platform from Beckhoff allowed Eclipse engineers to program G code that enabled the XTS and Beckhoff AM8000 servomotors to perform coordinated motion for high-precision dispensing.

With this innovative design, the updated transmission pump assembly system met the specified cycle time of 20,2 s per part with the micron-level accuracy required. The system has produced 1000 parts per shift, running the two parts in separate batches. The easy release and attachment of pallets, along with the instant automatic indexing of XTS, almost eliminated changeover times, reducing them from more than an hour to just one minute. Both controls and mechanical engineering ensured easy release of the pallets without removing a single bolt.

“Eclipse has innovation in its DNA,” says Werner. “For programming pallet control, pallet offset tables and similar requirements, Beckhoff offers many advantages compared to other options, and saves a significant amount of engineering time. With Beckhoff’s help we have tackled many other unprecedented high-speed and micro-assembly applications, including Covid test kits.”

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved