Some call EtherCAT “the Ethernet fieldbus,” which does not do it justice because there has always been controversy about using Ethernet as a fieldbus. A fieldbus is the mechanism for a controller to talk to the device level: the sensors, the actuators, the servo drives, etc. We are not talking about Industrial Internet of Things (IIoT) or cloud mechanisms. We are talking about mechanics – the devices that make things work.

What matters here are temporal determinism and ease of use. Industrial controllers need to communicate with field devices on a consistent time basis. This just does not work well with an IP-switched network. There are too many delays, latencies, costs and wasted overhead for an IP-based Ethernet protocol to be of much use in modern control systems.

How does EtherCAT get around this?

EtherCAT is not an IP-based protocol. It uses standard, unmodified Ethernet frames in a special way.

Rather than generating an Ethernet frame for every device in the field, EtherCAT generates one frame. As the system boots up, an EtherCAT controller polls every field device and asks, “Who are you? What are you? What are you reading? What are you writing? Okay, when the Ethernet frame comes through the system, this is your pointer to your data.”. Nothing else is needed. The device does not have to be specifically addressed.

This does two things. First, the controller only needs to copy a segment of data directly from memory, populate the Ethernet frame, and send it on its way. Second, the controller’s CPU is not tied up with bit-wise memory access and is freed up to handle its main job of control rather than dealing with the fieldbus.

This is called implicit addressing. As the frame goes through the system, each EtherCAT field device knows where its data is in the frame (kind of like assigned seats on a train). Explicit addressing is not needed. It’s better to think of EtherCAT as a shared memory because it reads and writes data directly to controller memory.

One frame talks to all field devices, rather than having to generate a separate frame for each. It makes the most of the ubiquitous Ethernet physical layer, meaning that normal Ethernet components are used. Nothing about EtherCAT negates the IEEE 802.3 Ethernet physical layer. The EtherCAT Technology Group (ETG) calls this methodology ‘Ethernet on the fly.’ A video accessible via the short URL www.instrumentation.co.za/*oct22-ethercat illustrates this functional principle.

Full-duplex system without switches

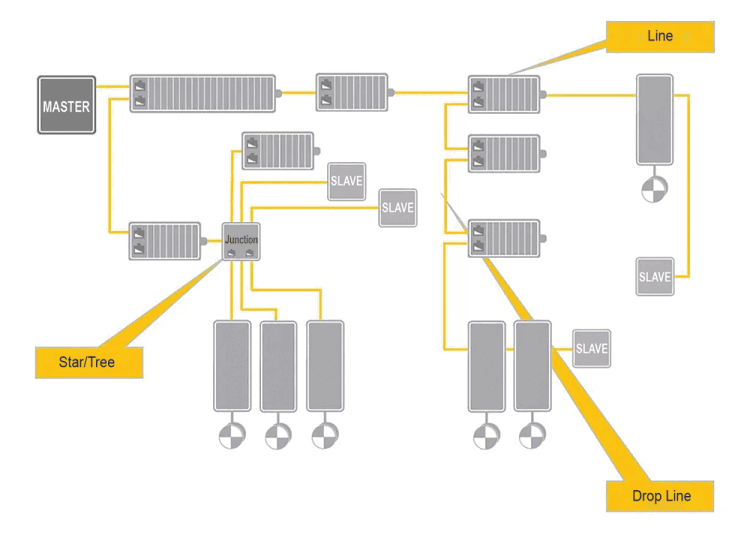

EtherCAT is touted as a performance bus, which it is, but it is often overlooked that EtherCAT also has a flexible topology thanks to its special functional principle. EtherCAT is a full-duplex system without switches. This makes line topology possible, which is always more suited to industrial systems than a star-connected, switched-based topology (in theory, switch-based approaches support line topology as well, but in practice, cascaded switches are to be avoided). And if one needs to do a drop from the line, that is also possible with EtherCAT – even complex tree topologies are supported.

There is infinite topology flexibility, even including media redundancy or hot-connect groups. You can connect devices any way that works best with the system. No matter how the system is connected, it looks like a ring to the controller. This saves on design effort and cost, and simplifies installation as no complicated network configuration is necessary.

There is only one EtherCAT version

A huge advantage of EtherCAT is that there is only one revision: Version 1. There are functional enhancements, but an EtherCAT device developed today can still replace a device developed in a network that was deployed 15 years ago. The basic EtherCAT functionality has never changed, and no one expects there to ever be anything but EtherCAT 1. This is because EtherCAT was well thought out from the beginning.

Why does EtherCAT use 100 Mbps Ethernet?

Because of the efficiency in the way EtherCAT uses Ethernet, there is rarely a reason to even think about a gigabit network. Gigabit Ethernet is no saviour, though it is often touted as such. 100 Mbps has many advantages: greater noise immunity, lower hardware costs, less heat dissipation and a larger product offering. The PHYs (physical layers) and magnetics are ubiquitous and inexpensive.

We are often misled into thinking gigabit is always better. One could agree when talking about consumer technologies, but for an industrial control system (ICS), gigabit leads to much greater costs and complications, especially on the device end. Do you really need a gigabit interface to a sensor?

So, while EtherCAT with 100 Mbps meets virtually all cycle time requirements today and into the future, there are more and more devices and applications that require more bandwidth. Therefore, development has started on EtherCAT G, with which EtherCAT will also support bit rates of 1 Gbps and beyond. This will coexist with the thousands of existing 100 Mbps EtherCAT devices.

EtherCAT G will not make the existing EtherCAT devices obsolete; it will be another extension used for devices like vision systems, high-sampling-rate measurement applications and extremely advanced, coordinated-motion systems. Above all, it does this while keeping the vast selection of existing EtherCAT

100 Mbps products available. Not only that: the combination of gigabit backbone and 100 Mbps segments for field devices maintains robustness and low cost while providing more bandwidth for those who need it. Vendors will not have to redesign their products for a different physical layer.

Simplicity is king

EtherCAT strives to make things simpler and easier to use. There is no IP or MAC address handling, no switch or router configuration, no topology limitations and no security issues. Users don’t even have to thoroughly understand the underlying design. That is the point. This is even true of distributed clocks, which are used to synchronise a system in the order of nanoseconds.

There is a simplicity in using EtherCAT, regardless of the controller or device. There is a well thought-out consistency behind all EtherCAT components using the same format. This is purposeful and promotes ease of use when working with any EtherCAT device.

EtherCAT diagnostics

EtherCAT uses several Ethernet 802.3 technologies in a unique way. One is link-lost detection. We have all seen our PC’s Ethernet LED go green after plugging into a network. This is built into Ethernet. The physical link detection is monitored by EtherCAT and if a link is broken or lost, the EtherCAT device will close the port, return the frame and inform the controller a link is missing.

Furthermore, each frame is monitored for bit errors by each device, and if there is one, its origin is also located. This allows for pinpoint diagnostics. Most EtherCAT network issues are caused by cables and connectors. Having exact error localisation is a great benefit and one of the reasons EtherCAT has become so popular in the entertainment industry.

Conformance and interoperability

All this means nothing if field devices cannot be accessed and configured without a lot of effort. The ETG is focused on conformance and interoperability. Facilitating interoperability between controllers and field devices is complex and very important. A user needs to be confident the selected devices will always work.

Every EtherCAT vendor is obliged to use the EtherCAT Conformance Test Tool, which performs a self-test of a field device. The device can still be sent to an accredited test laboratory, where it receives a certificate after passing the test – in addition to a confirmation for users, of course.

The EtherCAT Conformance Test Tool is continuously refined. The ETG learned lessons from older fieldbuses which offered static conformance tools that quickly became dated. Consequently, vendors wasted much effort with old or alternate revisions of a conformance tool.

To protect the EtherCAT technology, the ETG has issued a set of policies that all members have accepted collectively. These serve to ensure implementation conformance, thus ensuring the interoperability of the devices. The licensing policy also serves the same goal: to provide access to the technology for all device vendors, while avoiding variations that cause problems in the field of operation.

No single vendor has all the answers. Having the ability to choose the devices that are best suited to controlling your system is a huge advantage.

Control systems require a reliable communication network

The EtherCAT Technology Group feels the communication network is the single most important technological component of a control system. One of the messages of the ETG is to select this network first, then the controller. EtherCAT has many advantages to the control system integrator, with ease of use and strong diagnostics for the end customer.

© Technews Publishing (Pty) Ltd | All Rights Reserved