The company's success story began on January 4, 1922, when Anton Paar founded his machine shop. At that time, no one would have imagined that this one-man operation would one day become a global corporation with currently more than 3500 employees.

From the rough to the detailed

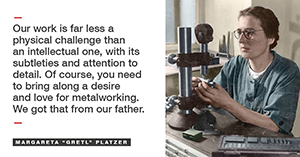

Even in the early years of the company, Anton Paar planned for the long term and involved his family, so his two daughters Hermine and Gretl worked in their father's business. While Hermine was responsible for the bookkeeping, Margareta worked in the workshop. Later Anton Paar gradually withdrew from the business. Gretl, at that time the first female master machinist in Styria, took over the management. The proper training of apprentices was especially close to her heart.

Gretl’s expertise and talent in the field of precision mechanics and manufacturing and also her intensive interaction with universities and research institutes, formed the basis for many inventions. A milestone was the cooperation with the Technical University of Graz in Austria, resulting in development of the Kratky small-angle X-ray camera, the first scientific analytical instrument to be produced by Anton Paar.

Expansion to world market leader

From the 1950s onwards, the company focused on measuring and analysis technology – the ultimate beginning of the success story. From beer, wine and soft drink producers to pharmaceutical and cosmetics companies to chocolate or cellphone display manufacturers – they all rely on the technical know-how and instruments of the Anton Paar Group.

In 1963, Gretl’s son-in-law, Ulrich Santner, took over the management of the company. He set the foundation for the company's expansion in the field of measurement technology later on. Ulrich made contacts with universities and contributed to the transfer of new technologies from research to industry. Finally in 1997 his son-in-law and current CEO Friedrich Santner joined the management.

Many new sales and service subsidiaries were established under his leadership and complementary measurement technology companies were acquired. As a result, the company's growth has been strong, both in terms of sales and number of employees. Anton Paar now has 45 sister companies and subsidiaries as well as 50 sales partners and operates in more than 110 countries around the world. Friedrich Santner also focused on expanding internal research and development.

Charitable foundation and the fifth generation

The non-profit Santner Private Foundation has owned the company since 2003. The foundation has two purposes: to promote non-profit science and research as well as to prevent and combat drug addiction. In January 2020, Friedrich Santner's sons, Jakob and Dominik Santner, joined the company's executive board, making it the fifth generation to be part of the management team.

For 100 years now, the company has combined high precision technology with scientific curiosity and a thirst for research. Among other things, this has made Anton Paar the world market leader in the fields of density and concentration measurement, rheometry and CO2 measurement.

"Talent, commitment and inner cohesion, in both successful and difficult times, have always distinguished us and our company. With these attributes, we are confidently entering the second century of our history," says Friedrich Santner.

© Technews Publishing (Pty) Ltd | All Rights Reserved