Most process plants have auxiliary services that do not require sophisticated instrumentation; more basic sensors are adequate, while also being more cost-effective.

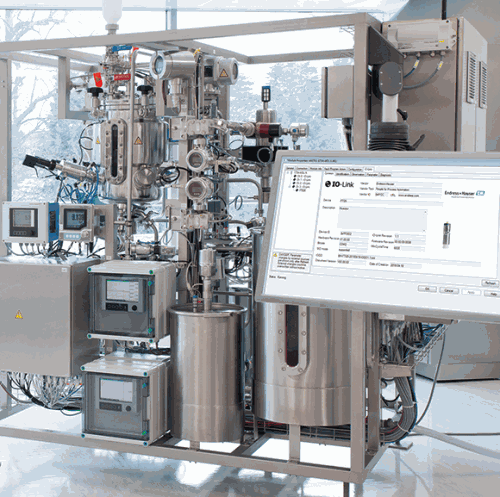

IO-Link offers an easy way to integrate these devices. It comprises IO-Link masters (comparable to a remote I/O), each with IO-Link devices, which can be sensors or actuators, connected via standard three-core cables. It is typically a subsystem of a larger, plant-wide monitoring and control network.

IO-Link master-device communication uses a digital point-to-point UART protocol rather than fieldbus networking. This manages the transfer of parameters to devices and collection of diagnostic and measurement information from them. The IO-Link master exchanges data with higher levels through Profinet, Ethernet/IP and many other protocols.

As an industrial communications networking standard, IO-Link’s devices, while more basic, still offer the data-rich visibility and controllability benefits of digital technology. The standard that applies to IO-Link, defined as IEC 61131-9, has now evolved from version 1.0 to version 1.1.

What challenges does IO-Link address?

For traditional systems, the loading of parameters for system and machine commissioning has always been a costly and time-consuming factor. Time and expense can similarly be wasted reloading parameters after instruments have been swapped out – and this parameterisation must be performed online, causing further production delays.

This is also a problem in a system manufacturing environment. Time is lost as the same parameters are entered into each unit of a system production batch.

Once in operation, such systems can be prone to failure and downtime as sensors do not provide status data to help spot latent problems. Even without a significant system failure, identifying and diagnosing problems in traditional instruments can be difficult and time-consuming and may require the expertise of a skilled technician to resolve.

Logistics complexity and delays can also arise, as well as onerous stocking costs, if a process needs multiple devices with varying configurations. Often, differences between sensors can be small, for example 0 to 10 bar versus 0 to 100 bar. Nevertheless, this represents a difference in parameterisation which may have to be performed by the instrument vendor. This is exacerbated if each device type calls for its own cable and/or connector, possibly of elevated specification.

IO-Link is a solution that can be used anywhere except in hazardous areas. It offers solutions to these issues through its communications capabilities. In a standardised environment, each sensor has a unique identification comprising a vendor ID and a device ID. It can continuously deliver data packets that include 32 bytes of process data, a status bit, parameter and diagnostic device data and event data such as error messages.

Planning and parameterisation of an IO-Link system can be performed using I/O Device Description (IODD) and an engineering tool. This allows easy device configuration, while stockholding for different device types is reduced. Parameterisation can be performed remotely, offline or online, using the engineering environment of the automation system. Complexity on the factory floor is also reduced, as all IO-Link device types connect to their IO-Link masters via standard 3- or 5-core unshielded cables and use industry-standard M12 connection plugs. Cables can be up to 20 metres in length.

Once the system becomes operational, maintenance, repair and operation (MRO) is accelerated. New repair and maintenance concepts become possible through IO-Link’s self-diagnosis and self-parameterisation capabilities, with value added to process measurements by detailed status and error data. Sensors often provide other values, such as temperature, alongside the main measurement, or continuous measurement values alongside a switch status.

IO-Link functions as a compelling alternative to simply monitoring non-digitalised devices such as 4-20 mA transmitters or digital input switches, which permit only one process variable per cable pair. Such devices also require scaling and local configuration – operations that must be repeated manually every time a device is exchanged.

How does IO-Link benefit users?

IO-Link offers easy and efficient integration through the use of standardised function blocks. It also complements Industrial Ethernet well, since high-end Ethernet devices can operate alongside more basic IO-Link sensors and actuators.

A traditional control system’s wide variety of sensors would have many different analog and digital signal types – digital in (DI), digital out (DO), PNP, NPN, pulse, 0-10 V, 4-20mA and possibly others. These would all generate requirements for their own connector and cable types. By contrast, all IO-Link devices use a common standard cable, which reduces inventory stock-holding, complexity and installation time. Once installation is complete, commissioning and start-up are accelerated by the automated setting of parameters.

If problems occur, the system provides diagnostic information with cause and remedy; this includes cable break detection. If diagnostics indicate that a device needs changing, this can be facilitated through automatable parameter data storage and download.

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved