In today’s downstream business environment, survival hinges on three key challenges: productivity and efficiency optimisation in the short term; digitalisation to help maintain the short-term gains/cost savings; and sustainability through portfolio management to position for longer-term success in the energy transition.

Energy efficiency as the starting point

The pursuit of energy efficiency remains the easiest and lowest-risk source of energy cost reduction and decarbonisation. It can also alleviate some of the short-term variable cost pressures. To ensure all three aforementioned challenges are met, asset owners and operators must embark on a digital transformation journey that starts with energy efficiency. Through energy efficiency, operators can demonstrate significant carbon reduction and save money with minimal impact to production.

However, current energy management methods often lack structured and automated digital technologies to identify and sustain performance improvements. The situation is further exacerbated by inconsistent data and inaccurate tools.

A contemporary digital energy management system (EMS) must provide all necessary information, analytical tools and implementation enablers required at all levels of the organisation, from top management to operators, to achieve decarbonisation goals in a focused manner. These include automated idea generation, achievement and sustainment.

KBC (a Yokogawa company) determined that the introduction of technologies including digital twins and artificial intelligence/machine learning (AI/ML) into a digital energy management system (D-EMS) provides the real-time accuracy, data consistency and information visibility, as well as the long-term performance sustainability that businesses need to navigate the energy transition.

Real-time data combined with a single, asset-wide digital twin and proprietary analytics capabilities enable automatic opportunity identification and performance gap breakdown. This applies to entire utilities systems and processing equipment.

In this way, improvement areas can be highlighted in real-time and daily facility energy improvement opportunity lists can be provided to closed-loop systems and operators to make changes. Furthermore, the efficacy of planned capital projects can be tracked with accurate projections so operators can make faster, informed decisions for capital allocation throughout the implementation cycle.

Holistic and connected digital twin

For certain unit processes and operations, a process and utility digital twin can ensure that the yield vs. energy trade-off for the entire operating envelope is properly considered. The digital twin can accommodate a high data volume consisting of process variables and a wide array of operating modes. To be relevant to the business and allow useful prioritisation, the evaluation also considers the dynamic nature of supply pricing and the variability of process demands.

The latest D-EMS uses a process digital twin that accounts for these changes in real-time. It connects energy real-time optimisation with process/yield conditions, state-of-the-art thermodynamics, electrochemical corrosion and scaling analytical prediction and remote asset performance monitoring of pumps and turbines. Combining this analytical output into the engineer’s visualisation makes the full impact transparent. It also directly provides the need for action with the operator’s visualisation. In this way, convergence in understanding and action is achieved between stakeholders.

Targeted actions using AI and ML

While machine learning algorithms are not new, enhanced computing power and cloud storage are key enablers that allow such algorithms to be fully leveraged.

Artificial intelligence using correlation-based analytics will have a strong role to play in driving energy management because it is relatively simple to use and fast to execute. It appeals particularly to the IT organisation because it relies on more familiar technologies and does not require deep chemical, mechanical or electrical engineering knowledge. It does, however, need some added intelligence in order to overcome its shortfalls.

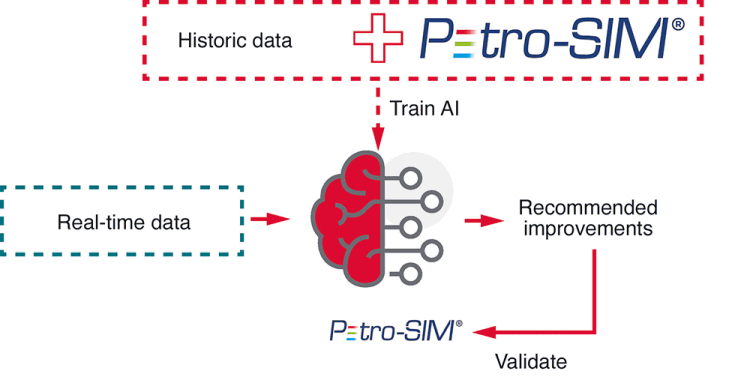

The ‘first principles’ model, in the form of the process digital twin described above, can act as the training ground for a correlation-based AI algorithm. First principles models can explore operating worlds beyond operating windows the plant has experienced and generate valid linearised models for the AI to use in those previously unencountered regions. The combination of synthetic data and plant data to continuously train machine learning algorithms allows real-time solutions to be recommended directly to operators and engineers at the moment of greatest impact. The architecture of such a setup is shown in Figure 2 using Petro-SIM as the first principles analytics package.

Case study

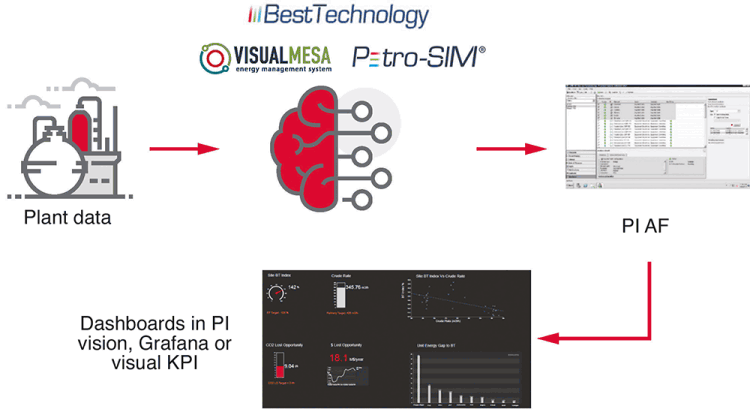

KBC recently implemented a D-EMS with an international oil company that operates multiple refining assets globally. The central energy team needed to drive a consistent approach to energy improvements and sustain its energy performance with a reduced effort. It also looked to the D-EMS to help it facilitate effective capital deployment from the corporate budget. The solution architecture is shown in Figure 3. Measured and calculated values are converted into a PI asset framework (AF), which arranges the data into a certain predefined hierarchy. Dashboards are then generated using the asset framework in any desired dashboarding environment. A standard asset framework and hierarchy makes dashboarding seamless for the end user.

The first phase of the project involved focusing on the D-EMS to visualise and analyse areas within process units at two refineries. A digital twin of the two process units was constructed and connected to the data, allowing visibility of the performance to the corporate and on-site teams. This gave them real-time access to a current gap breakdown with granular energy gaps at the unit, systems and equipment levels. The company’s subject matter experts were also able to easily compare gaps in specific items of equipment across both refineries.

At the heart of the technology framework is the digital twin that completes the advanced analytics. Machine learning-based AI algorithms are additional to this core framework and utilise data generated and stored in the time series databases. Opportunity realisation through closed-loop control also links to the digital twin, taking additional inferred data and information and thereby enhancing opportunity outcomes.

The central team is using the opportunity identification and prioritisation to decide on capital spending as well as providing an automated benefits calculation in real-time to provide confidence in its decisions. The realisation of the project is anticipated to provide sustained cost reductions in the order of $100 million per year and a saving of 1,0 million tons per year of CO2.

Summary

There are strong political, economic and technical forces driving the energy transition. Selecting the right path requires foresight and skill. Winners will possess strong leadership, an agile organisation and a willingness to let go of the status quo in their business.

The new D-EMS is a solution that drives a facility’s energy transition by empowering stakeholders with advanced digital technology to identify, implement and sustain cost and carbon performance. Harnessing existing cashflows, moving with the markets and optimising assets will position the business for the transition.

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved