For the digitalisation of its industrial cleaning machines, the French company Mecanolav counts on IO-Link sensors from ifm electronic. By connecting intelligent IO-Link sensors with the Smartobserver software, Mecanolav has become the first company to offer cleaning machines on the market that are fit for Industry 4.0. The data is collected by IO-Link masters and then stored and visualised using the Smartobserver software. This is how monitoring and maintenance can be ensured for each connected machine around the globe.

Managing director, Matthieu Vollois, elaborates: “Most of the sensors we use on our machines are supplied by ifm. Recently, we chose to digitalise our machines because this is the road to the future. Industry 4.0 is coming, and we want to be the first on the market to offer fully connected cleaning machines.”

The individual processes at a glance

The level in the water tank is controlled with an LR2050 level sensor. It features a probe and detects the level by means of guided wave radar. Four switch points are programmed via IO-Link. Two of them detect the high and low levels. The third, upper switch point serves as overfill protection, while the fourth, lower switching point serves as run-dry protection. It protects the suction mechanism of the wash pump and ensures that the heating unit is constantly below the water surface.

The water temperature is controlled and monitored by a TA2437 temperature sensor. The target value is 60°C. If the temperature drops below 45°C due to a malfunction of the heating unit, a switch-off will occur as the cleaning agent will no longer be effective.

While the machine is running, water is pumped out with a pump and filtered with a bag filter. A PN7094 pressure sensor behind the filter checks it for contamination. The target value is 5 bar. At 3,5 bar a warning alarm is triggered, and at 3 bar the main alarm is triggered.

During rinsing of the metal parts, an SM9000 flow meter controls the flow rate required for cleaning. To ensure optimum cleaning of the workpieces, a flow rate of 150 l/min is necessary. The SM9000 flow meter also features a total quantity meter and measures the medium temperature. The water circuits are controlled via valves. Behind each valve, a PN7094 pressure sensor ensures the correct water pressure (5 bar).

In both drying circuits the air flow is monitored with an SD2000 air meter. For the workpiece to dry completely, the flow rate must be 250 cubic metres per hour.

When lifting the part to be cleaned at the beginning of the cleaning cycle and lowering it at the end of the cycle, an O5D100 laser sensor detects the presence of the part carrier.

In addition, an IO-Link DV2510 light tower clearly indicates the machine and alarm states.

Vibration analysis

Four VSA001 acceleration sensors in combination with the VSE002 diagnostic electronics monitor the rotating elements of the cleaning machine for wear and malfunctions. These include the wash pump, the rotary engine of the mechanical ramp, the fan for the extraction of vapours and the servo motor. Early detection of imminent mechanical damage to the bearings enables condition-based maintenance. Unplanned failures are reliably avoided.

Headstart with IO-Link

Today IO-Link sensors offer completely new options. For example, additional sensor data is generated to achieve maximum efficiency and cost savings. This allows process transparency from the machine to the ERP system to optimise existing automation. Furthermore, IO-Link has more to offer.

The entire measured value transmission is digital. Transmission that is prone to errors and conversion of analog signals is replaced. The digitally transmitted measured values can be directly displayed in the control room.

IO-Link data transfer is based on a 24 V signal and is therefore extremely insensitive to external influence. IO-Link sensors are connected via standard M12 connectors and screened cables with associated grounding are no longer necessary. The IO-Link master saves all parameters of the connected sensors, meaning that after replacement the previous parameters are automatically written to the new sensor, eliminating the need to look up the required sensor settings.

IO-Link ensures unambiguous device identification. Sensors with IO-Link capability are clearly identified by vendor and device ID. Exclusive use of original spares is ensured and the standardised parameter setting allows locking of the operating keys on the device. This eliminates the chance of values being incorrectly set and makes documentation of the sensor parameters possible at any time.

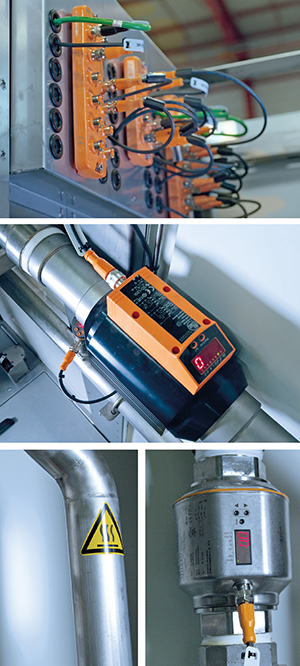

With IO-Link, the transfer of process and service data takes place simultaneously. Wire-breaks or short-circuits are immediately detected by the master. Diagnostic data can be accessed even during operation with no additional analog cards required in the controller. In addition, space is saved in the control cabinet since the IO-Link I/O modules, rated IP67, can be located outside the cabinet. Mecanolav relies on the AL1102 IO-Link masters with Profinet and eight ports, and the AL2330 IO-Link I/O modules, both from ifm.

Production data acquisition with the Smartobserver

The ifm Smartobserver software is used to monitor and analyse all sensor data. Michel Astier, sales manager for the automotive industry, elaborates: “ifm offers Mecanolav a complete solution ranging from intelligent sensors to the collection of data that is made available via the Smartobserver, which is used to visualise all sensors and actuators on the machine. This makes scheduling maintenance much easier and, moreover, this data can be viewed anywhere in the world, no matter where the machine is actually located.”

The Smartobserver also offers the corresponding tools for condition-based maintenance, in this case vibration monitoring.

Conclusion

Digital communication down to the sensor level, in combination with powerful software for analysis and visualisation, forms the basis for the digital factory and Industry 4.0. Mecanolav has followed this path successfully with the support of automation specialist ifm.

Vollois sums it up: “As a company, ifm is not only innovative, but also extremely reliable, which is important to us. With ifm we not only have support in France, but also across the world. We need good service and support, and we get both from ifm.”

| Tel: | +27 12 450 0400 |

| Email: | [email protected] |

| www: | www.ifm.com/za |

| Articles: | More information and articles about ifm - South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved