Remote I/O system reduces TCO in hazardous areas

April 2017

Fieldbus & Industrial Networking

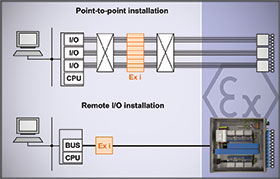

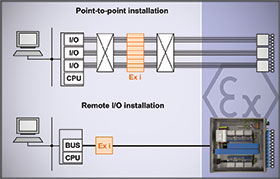

For greenfield projects and plant retrofits, the market-leading IS1+ Remote I/O system from explosion protection specialist R. Stahl is a future-proof and highly cost-effective solution for data transmission in hazardous areas (zone 1 and 2). Compared to conventional point-to-point wiring, the system greatly reduces the wiring effort. Even for a limited number of signals and a control system installed only a short distance away, installations become quicker and cheaper. However the system offers the most significant savings potential in the engineering and commissioning stages, depending on plant size. Typically 40% cost savings compared to conventional installations can be achieved. The integrated predictive maintenance and diagnostics features of IS1+ according to NAMUR NE 107 also ensure maximum process availability and low operating expenses. The fully intrinsically safe structure with an intrinsically safe fieldbus based on Profibus DP or industrial Ethernet Modbus TCP, EtherNet/IP or Profinet facilitates a simple and easy expansion or modification of the system in hazardous areas: modules can be hot-worked or hot-swapped at any time.

IS1+ includes a range of multifunctional modules, such as an eight-channel module for analog inputs and outputs with HART, a 16-channel module for digital inputs and outputs, or an eight-channel temperature module for 26 different temperature sensors. The signals can be configured individually for each channel. In addition, for almost all intrinsically safe and non-intrinsically safe solenoids, R. Stahl supplies digital output modules which offer eight integrated pilot valves. Thanks to the innovative low power technology, IS1+ system modules feature a long service life of up to 15 years. They are suitable for use in an expanded temperature range between -40 and 75°C, even in extreme ambient conditions. For installations in zone 2, the series also includes cost-optimised input and output modules that are functionally identical.

For more information contact Preshan Moodliar, Stahl Esaco, +27 (0)11 608 3120, [email protected], www.esaco.co.za

Further reading:

Beckhoff expands economy drive system

Beckhoff Automation

Fieldbus & Industrial Networking

Beckhoff’s new AM1000 servomotor joins the company’s economy drive system. The compact, powerful motor and the AX1000 servo drive provide users with a perfectly coordinated, cost-optimised drive system.

Read more...

CC-Link IE Field supports egg carton production

Fieldbus & Industrial Networking

Huhtamaki’s Franeker plant in the Netherlands manufactures more than 11 million egg cartons every week using recycled paper. To support its highly automated lines, the site has begun upgrading its automation systems from older serial network standards to CC-Link IE Field, an open industrial Ethernet technology that offers faster performance due to gigabit bandwidth and better diagnostics.

Read more...

Ultra-compact industrial PCs exploit advances in CPU technology

Beckhoff Automation

Fieldbus & Industrial Networking

Beckhoff’s C60xx scalable series of ultra-compact industrial PCs combines high computing power in an extremely compact format with a wide range of options for installation in the control cabinet.

Read more...

How to protect your industrial network

RJ Connect

Editor's Choice Fieldbus & Industrial Networking

Network security is no longer a matter of preventing hacking or data breaches. Traditional defence mechanisms for perimeter protection may not fully address internal threats or device-level vulnerabilities alone.

Read more...

High-speed precision and simplified architecture for slicing systems

Fieldbus & Industrial Networking

When KFT Food Machinery needed a way to support ultra-fast, multi-axis motion control in its slicer range, it turned to CC-Link IE TSN – the open industrial Ethernet technology from the CC-Link Partner Association (CLPA).

Read more...

Precise, synchronised control for automated steel mesh handling system

Fieldbus & Industrial Networking

Automation specialist Hambi Maschinenbau has developed a world-first system that automates the cutting, handling and stacking of heavy reinforcing steel mesh – a task that previously required up to six human operators.

Read more...

Loop Signature Part 2-1: Loop signatures and process transfer functions

Michael Brown Control Engineering

Fieldbus & Industrial Networking

The previous series of loop signature articles dealt with the basics of control loop optimisation, and concentrated on troubleshooting and ‘SWAG’ tuning of simple processes. In this new series, consideration will be given to dealing practically with more difficult issues like interactive processes, and with processes with much more complex dynamics.

Read more...

Smart and seamlessly integrated I/O upgrade

Beckhoff Automation

Fieldbus & Industrial Networking

Beckhoff’s entire portfolio of EtherCAT terminals is now undergoing a technological upgrade while remaining fully compatible with the existing series.

Read more...

Introduction to Part 2 loop signatures and process transfer functions

Fieldbus & Industrial Networking

The previous series of loop signature articles dealt with the basics of control loop optimisation, and concentrated on troubleshooting and ‘SWAG’ tuning of simple processes. In this new series, consideration will be given to dealing practically with more difficult issues like interactive processes, and with processes with much more complex dynamics.

Read more...

Siemens sets new standards in drive technology

Fieldbus & Industrial Networking

Siemens is setting new standards in industrial drive technology with the launch of its new high-performance drive system, Sinamics S220. This offers a seamless and innovative drive system with comprehensive simulation and analysis capabilities and advanced connectivity features that enable full integration into digital work processes.

Read more...