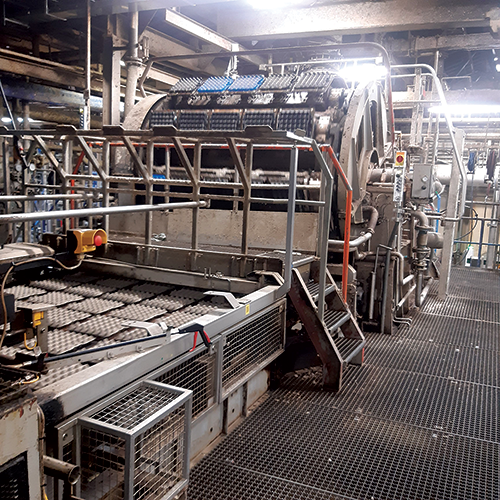

Huhtamaki’s Franeker plant in the Netherlands manufactures more than 11 million egg cartons every week using recycled paper. To keep this production moving around the clock, the factory relies on highly automated lines that must be stable, easy to maintain and adaptable to future needs.

To support this aim, the site has begun upgrading its automation systems from older serial network standards to CC-Link IE Field, an open industrial Ethernet technology that offers faster performance due to gigabit bandwidth and better diagnostics. The change has already been implemented on the plant’s production lines and has delivered impressive results by streamlining maintenance through clearer diagnostic data, reducing complexity and cutting troubleshooting time. As a result, CC-Link IE Field will now serve as the standard for the site’s future upgrades.

Long-term investment in automation

The Franeker facility operates with an efficient engineering team responsible for both maintaining legacy equipment and developing new solutions in-house. Having worked with Mitsubishi Electric hardware for several decades, the site has gradually upgraded its systems to iQ-R series PLCs and CC-Link IE Field.

“We try to avoid making constant changes,” explains Albert Bruining, electrical engineer at Huhtamaki. “We want systems that will still be working 10 years from now. When we do update our technology, it needs to offer clear, long-term benefits. That was the case with CC-Link IE Field.”

The new network was introduced as part of a larger control system upgrade, which also involved updating the PLCs, inverters and HMIs on a legacy machine. Moving to CC-Link IE Field brought benefits, including improved fault diagnostics, a more flexible wiring structure and simpler hardware configurations. These have made both commissioning and long-term support significantly easier for the engineering team.

Improved diagnostics reduce downtime

One of the main reasons for moving away from their previous networking setup was the limited availability of diagnostic data. “With our old systems, you can tell whether a device is online or not, but that’s about it. That means that if there’s a fault, it’s harder to pinpoint the cause,” Albert says. “You might need extra meters or software tools to figure out where the problem is. With CC-Link IE Field, diagnostic information is readily available and easier to integrate directly into the PLC and HMI. That means clearer error messages for the maintenance team and faster fault resolution. If there’s a communication error, the HMI can tell you exactly which node or cable is involved. That makes troubleshooting much quicker and more efficient.”

This level of insight is incredibly valuable in a 24/7 production environment where downtime has a major impact on throughput and carefully planned delivery schedules.

A flexible and simplified network

Alongside improved diagnostics, the move to CC-Link IE Field also offered practical installation and maintenance advantages.

Unlike serial networks, which rely on daisy-chained connections, the Ethernet-based structure of CC-Link IE Field allows for a star topology using standard switches. This means that a fault in one cable won’t take down the entire network, another important factor in ensuring the availability required to keep an operation on the scale of the Franeker plant running.

The use of standard cabling also proved beneficial. “With our old technology, you need special cables that aren’t always easy to source,” explains Albert. “With CC-Link IE Field, we can use standard high-quality Ethernet cables, which makes sourcing and logistics much easier.”

In addition, newer frequency inverters from Mitsubishi Electric come with CC-Link IE Field built in, eliminating the need for expansion boards previously required for their existing solution. “It reduces the number of components we need to install and support,” adds Albert. “That keeps things simpler.”

A standard for the future

The success of the recent upgrade has led the engineering team to adopt CC-Link IE Field as the site standard for future automation projects. As older machines are phased out, the new network will be rolled out more widely across the plant.

The Franeker facility continues to design and build much of its machinery in-house using Mitsubishi Electric automation hardware. Since Mitsubishi is a strong supporter of CC-Link IE technology and a CLPA board member, the use of CC-Link technology is well established and continues to expand in scope.

“We also offer CC-Link IE TSN, making it easier for users to integrate high-speed control and enterprise-level data on one network. When future upgrades are planned by Huhtamaki, CC-Link IE TSN will allow them to meet the demands of digitalised manufacturing by providing the basis for a converged, gigabit, Time-Sensitive Networking architecture,” concludes John Browett, general manager of the CC-Link Partner Association.

For more information contact John Browett, CC-Link Partner Association Europe,

© Technews Publishing (Pty) Ltd | All Rights Reserved