Some of the products created for the consumers in the developed world have had perhaps surprising benefits in the less well-developed countries too. One example has been the use of mobile phones throughout Africa, enabling the development of a simple banking and payment system.

But there are other engineering developments that are specifically designed for use by people living far from the normal facilities offered in an urban setting, and many universities, philanthropists and aid organisations are active in supporting these ideas. One such development idea from the UK is known as a ‘Desolenator’. This is a portable, solar-powered water purification system, designed to produce clean drinking water, starting from seawater, or polluted groundwater. The device is the size of a flat-screen TV and is equipped with rugged all-terrain wheels to assist transport: it can produce 15 litres of distilled drinking water per day, enough for one family to use for drinking and cooking.

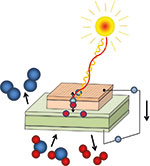

The device uses a solar panel to produce electricity: a thin layer of the water to be treated flows over the photovoltaic surface, absorbing the heat also produced by the sun, and cooling the panels to improve their efficiency. The heated water passes into a boiler, powered by the electrical output from the panel: the steam is condensed to produce distilled water, giving up its latent heat to the incoming water flow. A small drain from the boiler discharges a concentrated dirty liquid stream.

The Desolenator device is claimed to have a life of 20 years, and requires little maintenance: it has recently won two Innovation Award prizes from the UK’s Institute of Engineering Technology.

Further harnessing solar power

Whilst the Desolenator shows one potential application of solar power, making electric power available from such a widely available source is a major objective in both the developed and under-developed world. This is particularly needed in areas without any other source of power at night, when it is dark, which is a slight problem. How can children do their homework, or study anything, without some light?

In the developed world there is a need to store the power generated by wind farms and solar farms, to make it available in periods of high demand, or when the wind or sun are not there. So there is a lot of research into storing large amounts of power. Hopefully some of this might spin-off and make smaller domestic or small village units available soon.

At the Technical University of Vienna (TU Wien), current research is following the principles of photochemical cells, as used in nature, where plants absorb sunlight and store this energy chemically. The main problem was that quoted above, in relation to the Desolenator design, that at high temperatures, the efficiency of any current photovoltaic solar cell decreases. While the electrical energy produced by a solar cell can be used in an electrochemical cell to split water into hydrogen and oxygen, the energy efficiency of this process is limited, because of the high temperatures involved.

At TU Wien researchers have now developed new highly specialised materials, which form a photovoltaic that operates at a high temperature (400°C), so concentrated light beams can be used to produce a large energy output: currently achieving 920 mV. These cells use Perovskite metal oxide materials in the photovoltaic, which creates free charge carriers – electrons – that travel into the electrochemical cell. Here they ionise oxygen into negative ions, which can travel through a membrane, separating hydrogen and oxygen. Work continues to increase the power further and produce an industrial prototype, where a hydrogen cell would be used later to produce on-demand electrical power.

Other techniques

More conventional techniques, such as those having banks of rechargeable batteries, and even mechanical flywheel systems, are being installed in areas where short-term interruptions in supplies are common. But the spin-off from such university research will eventually lead to novel ideas to help the less-developed world as well.

Nick Denbow spent 30 years as a UK-based process instrumentation marketing manager, and then changed sides – becoming a freelance editor and starting Processingtalk.com. Avoiding retirement, he published the INSIDER automation newsletter for five years, and then acted as their European correspondent. He is now a freelance Automation and Control reporter and newsletter publisher, with a blog on www.nickdenbow.com

© Technews Publishing (Pty) Ltd | All Rights Reserved