The first machine of its kind changes robot tools for packaging machines fully automatically at Gerhard Schubert in Germany. With Festo’s valve range VUVG as one of their central components the TLM packaging machines achieve a hitherto unattained level of efficiency.

Small, large, round, square, aluminium, plastics, cardboard and composites – food packaging has never been as diverse as it is today. This is not just because of the increase in hygiene requirements but also because packaging is used as the brand identity for products and companies. This development also has an impact on the manufacturers of high quality packaging machines. They must be ever faster, increasingly flexible, more and more compact. And so the ‘hand’ of Schubert’s TLM P3 robot has become more and more complex over the years. Apart from the core task, holding the tool, the robot hand must also fulfil many additional requirements. These include, for example, transferring energy and data for the sensors and valves on the tool. It also transfers the relevant codes to the tool; but the more complex robots and tools become the more difficult the tool change turns out to be. Gerhard Schubert in Germany realised it was time for a fully automatic format conversion process using an automatic tool changer.

Transport in seconds

The principle of the automatic changing process is simple. With the new tool changer the TLM P3 robot takes the suitable format tool for the relevant product from a tool cupboard specifically designed to basic europallet dimensions and transfers it to a TLM transmodule. As the first transrobot in the world, the transmodule can move freely on the track system of a packaging machine. It is driven by a servo motor that engages into a gear rack by means of a toothed pinion. The energy and data are transferred inductively. The transmodule delivers the tools to their destination with a positioning accuracy of up to ±0,1 mm. Acceleration of up to 0,5 g ensures it gets there fast. The tool is removed and transported in about 40 seconds. Immediately after that the packaging machine starts the new format.

Progress with a tiny footprint

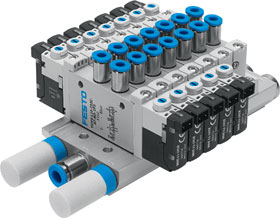

The central interface of the automatic tool changer is the valve range VUVG. It transfers energy and control pulses quickly and reliably; and its design is extremely compact. Its tiny footprint fits in well with the compact design of the automatic tool changer and means it can be fitted directly on the cylinder. A flow of up to twice that of traditional valves ensures high energy density with a pressure power of up to 10 bar.

The high level of modularity of the valve range was also advantageous for the development of Schubert’s automatic tool changer. By moving the packing glands, the base plate can be easily converted and adapted to the required functions. On the front individual valves can be replaced by dummy plates by undoing two screws and doing them up again. This is how Schubert makes up to 30 variations based on three components.

Low consumption, high availability

In this simple but intelligent way, the world market leader in top loading packaging machines is constantly increasing the flexibility of its equipment. Short tool changeover times, low energy consumption and continuous availability of the high-end machines give this company with its 40-year-old success story a decisive competitive edge in the market.

For more information contact Tracey Swart, Festo, +27 (0)11 971 5560, [email protected], www.festo.com

| Email: | [email protected] |

| www: | www.festo.co.za |

| Articles: | More information and articles about Festo South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved