Safe network communication in underground mines

July 2012

Fieldbus & Industrial Networking

Frequent coal-mine accidents prompted the Chinese government to embark on an ambitious plan to construct safety monitoring systems in 104 coal mines in 15 provinces.

The detection of hazardous or inflammable gases is particularly important for the security of coal mines, in China 95% of the coal mine accidents were caused by gas explosions. Gases that need to be monitored include methane, carbon monoxide and hydrogen sulphide. Advantech joined in the company’s plan in 2008, and has provided solutions based on fibre optic Ethernet ring for underground communication networks.

System requirements

As any hot-spot could cause a catastrophic blast in the underground coal shafts and roadways, the safety monitoring system itself has to be safe or it could become a source of danger. Copper based communication cable is therefore not an option for coal mines. Fibre optics is desirable, not only because it is safer but also because it provides faster and more reliable communications. Also, the switches and cables deployed in the coal mines must have strong anti-electromagnetic capability to prevent interference from facilities such as power substations and motor-driven power adaptors in the mine.

Solution description

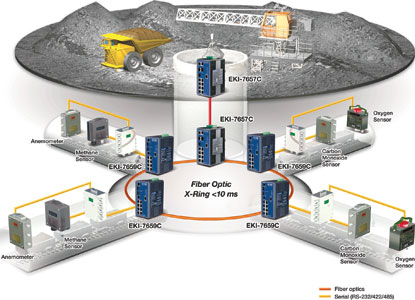

Advantech’s EKI-7659C switches are deployed in each roadway of the mine to transmit data collected from air sensors located inside the mine, including methane and oxygen concentration, wind speed and smoke. The data is sent to the backbone switch EKI-7657C (three fibre ports) via a redundant X-ring fibre optic network, and from there, up to the monitoring and control centre on the surface.

To avoid electromagnetic interruption, protective components are applied to the integrated circuits of the switches; also each switch is enclosed in an explosion proof enclosure to ensure maximum security and reliable operation. The equipment is certified with Chinese MA standards for coal mining security.

Conclusion

Coal mine accidents usually result in tremendous loss of lives and money. To avoid tragedies the investment on safety monitoring systems is necessary for modern coal mining industry. The coal mine safety monitoring system relies heavily on reliable information technology that provides secure and rapid data transmission, so that the administrators can detect any abnormal situations in the coal mines quickly enough to take action that prevents disaster.

Advantech’s fibre optic Ethernet switches with anti-electromagnetic capability and ruggedness can provide reliable and secure data collection and transmission in adverse underground coal mining environments. This saves lives and money.

For more information contact Fons de Leeuw, Profitek, 086 165 4321, [email protected], www.profiteksa.com

Further reading:

Fire and gas suppression solutions for mission-critical industries

Fieldbus & Industrial Networking

By representing world-leading brands and focusing on fully integrated, certified systems, HMA South Africa is positioning itself as a trusted partner in fire detection, suppression and explosion-proof safety solutions across the continent.

Read more...

The future of manufacturing

Fieldbus & Industrial Networking

Industrial automation is evolving at an unprecedented pace. At the forefront of this transformation is the Siemens SIMATIC ET 200SP HA Distributed I/O system. This is a flexible and scalable distributed I/O system for modern signal transfer from the field to the control level.

Read more...

Time-sensitive networking

RJ Connect

Editor's Choice Fieldbus & Industrial Networking

In this article, we will explore what is driving the rise of time-sensitive networking, how it is reshaping industrial efficiency, the challenges when deploying this technology, and ways to tackle these challenges.

Read more...

Loop Signature 30: Nonlinearity in control loops (Part 1)

Michael Brown Control Engineering

Editor's Choice Fieldbus & Industrial Networking

If nonlinearity occurs it means that if one is to carry on controlling with the same response to changes in load or setpoint, then the tuning of the controller will also need to be adjusted to meet the new conditions.

Read more...

PC-based control regulates innovative dehumidifiers

Beckhoff Automation

Fieldbus & Industrial Networking

Swedish company, Airwatergreen is breaking new ground in the dehumidification of air in industrial buildings and warehouses. The patented CVP technology reduces energy requirements and ensures an indoor climate that prevents corrosion and mould growth. PC-based control from Beckhoff regulates this innovative process.

Read more...

Ethernet connectivity for embedded systems

Fieldbus & Industrial Networking

Delivering Ethernet connectivity for embedded systems, XPort ETH Click is a compact add-on board from MIKROE, the embedded solutions company that dramatically cuts development time by providing innovative hardware and software products based on proven standards.

Read more...

Compact mini PC

Vepac Electronics

Fieldbus & Industrial Networking

AS AAEON’s first Intel Core-powered PICO-SEMI system capable of fanless operation, the PICO-MTU4-SEMI from Vepac Electronics is easily deployed as part of larger equipment setups or integrated as the central unit of smart robotics solutions such as AGVs, AMRs and drones requiring minimal maintenance.

Read more...

Future-ready I/O to redefine connectivity

Schneider Electric South Africa

Fieldbus & Industrial Networking

Schneider Electric South Africa has launched its state-of-the-art Modicon Edge I/O NTS. This future-ready I/O redefines connectivity, data aggregation and operational efficiency for industrial applications.

Read more...

Referro Systems delivers industrial connectivity

Fieldbus & Industrial Networking

To meet the growing demand for secure, flexible and reliable remote access for industrial network connectivity for its clients, Referro Systems has added Rockwell Automation’s Stratix 4300 to its inventory of products.

Read more...

Case History 199: Another example of the effectiveness of cascade control

Michael Brown Control Engineering

Editor's Choice Fieldbus & Industrial Networking

In my last article I wrote about how cascade control systems can effectively overcome valve problems. This article gives another example of how a temperature control was able to perform well, in spite of really severe valve problems.

Read more...