End-user details

Name: Details not provided by vendor

SI details

Name: Reinhard Dreyer

Designation: Executive Director

Company: Ecam

Phone: +27 (0)11 955 3379

E-mail: [email protected]

Product details

Product name and version: Vijeo Citect v7.20

Vendor: Schneider Electric

Phone: +27 (0)11 254 6400

E-mail: [email protected]

URL: www.schneider-electric.co.za

Application details

Location: Rustenburg

Industry: Mining

Location: Blantyre Malawi

Application: Winder monitoring and safety

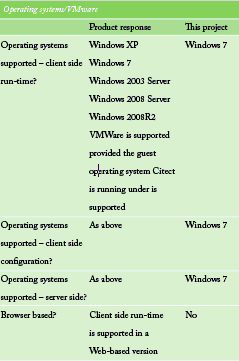

Server OS: Windows 7

Client OS: Windows 7

Application statistics

Tag count: 1000

Updates per day: 20 736 000 (240 tags per second)]

Front ends: 96 DI, 16 DO, 8AI 1 * Mitsubishi Q series PLC

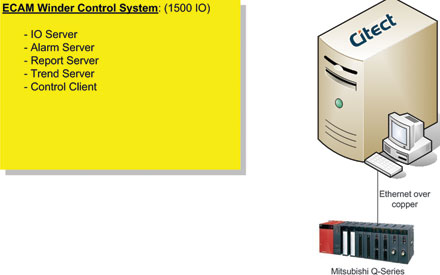

Licences: 1 * A single Citect SCADA server to address 1500 PLC tags

End–user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

The scada system has been successfully developed as a reusable OEM package to monitor various inputs on a mine winder. The system is responsible for tripping the winder drive if monitored inputs move outside specified limits. The project involved the expansion of an existing system and an upgrade to historical data-logging and supervisory software to work with the latest windows operating systems.

Q: What was the primary motivation for the project?

To develop a reusable mine winder package that is easy to engineer, simple to maintain and that delivers a clear picture of what is happening on the winder.

Q: What were the main goals established for the project?

1. To develop a solution that would scale without having to modify existing system hardware or software.

2. To move away from in-house bespoke development and shift the responsibility of supportability to the scada vendor by utilising commercial-off-the-shelf products. Thus transferring the onus of supporting Microsoft OS changes to the scada vendor (Schneider Electric).

3. To minimise time to market by developing re-usable libraries and making system parameters configurable.

Licensing, maintenance & support

Q: What upgrade agreements are in place for this application?

None. Upgrades will be handled on a project basis per customer request.

Q: How is the after-sales support handled on this particular application?

No support contract. Support is handled through service trips on a case-by-case basis.

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

No. Due to the safety-critical nature of the system, no remoting has been implemented.

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

No.

Management reporting and integration

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

Yes, utilising the standard scada Trend Server and built-in Process Analyst trend tool.

Q: Is the system integrated with an MES/ERP or other management reporting or control system? (e.g. Baan, SAP, SYSPRO…)

No.

Q: Who performed this management system integration and was any additional software development needed to accomplish this?

N/A.

Q: Have any production benchmarking tools been configured as part of the scada system?

No.

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

No.

Q: Are you currently using tablet PCs or mobile phones to interact with the scada system?

No.

End-user conclusion

Q: In the procurement decision making process was the Total Cost of Ownership (TCO) considered? If so, what were the primary TCO considerations that influenced the product selection?

No. The decision was made on existing product support and experience.

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Existing (earlier) solution from same SI.

Q: What single feature most impresses you about the product now that it is in operation?

Powerful extensibility features enable the system to handle any design criteria thrown at it.

Q: What impresses you most about the architecture?

N/A.

SI Responses

Project details

Q: Approximately how many man-hours did the scada configuration take?

3600 man-hours to develop the reusable package.

Q: What human factors were taken into consideration in the HMI design process?

Careful consideration and standardisation of colours, emphasis on clarity and visibility. For example, a device would be represented as green when in a running, healthy state, red when tripped and grey when not running.Security: Various levels of security had to be defined in order to make the system flexible enough to enable parameterisation from within the control system while at the same time preventing unauthorised changes.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Standard library.

Q: How would you describe the library of graphic images?

Rudimentary.

Q: Did you use any ‘special’ images (e.g. photographs, 3D images, specialised dashboards, etc.)?

No.

Q: Did you use any video or multimedia technology used in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system?

All events and alarms are logged to facilitate the investigation of sequence-of-events (SOE) in the event of an accident.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

A catastrophic failure (i.e. power outage where the system is totally shutdown) was tested to guarantee the winder stops in a safe state.

Q: What are the key physical communication layers and communication protocols employed in the system?

Scada communications to the Mitsubishi Q-Series PLC via Ethernet TCP/IP over copper using the MELSEC-Q protocol.

Q: What levels of redundancy are incorporated in this scada application?

None.

Q: What specific custom code or scada scripts were written for this project?

Cicode applications to generate reports and for displaying specific information.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

Built-in Citect authentication was used (native Citect role management was implemented).

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks.

No. The system comprising scada and PLC is standalone.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

N/A.

Q: What configuration backup and data archive backup methodologies have been adopted?

Each mine winder system is configured with a standalone Citect Server (Trend, Report, Alarm and I/O Server and Client) configured with RAID 1. No additional data archive methodologies have been implemented.

Q: Did you use any integrated or third-party configuration control system for the scada configuration during the engineering of this application?

No.

SI conclusion

Q: How would you rate the ease of use of the historical reporting system?

Fairly easy to use.

Q: What impresses you the most about the engineering/configuration aspects of the product now that it is in operation?

The stability of the system.

Q: What impresses you most about the architecture?

The solution architecture requires only a single standalone PC which caters to all the roles of the system (I/O, Trends, Alarms, and Reports). Citect is easy to implement in this configuration.

Vendor responses

Product

Q: Vendor comments on product/modules?

The current version and that used on the project are Citect 7.20 Service Pack 3.

Schneider Electric is committed to releasing one release per annum. We continue to enhance the product quality through service packs.

Operating systems/VMware

Q: Vendor comments on operating systems?

Schneider Electric continues to support the latest Microsoft operating systems including both 32-bit and 64-bit versions.

Licensing, maintenance & support model

Q: What sort of licensing agreement options are offered?

All modules are included in a licence.

Two licence types are available: Full Server and Client (either read only or read/write). This particular solution makes use of a Full Server licence which ships with a built-in client licence, offering full control.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Licence is a once-off purchase for a particular version.

Q: What upgrade agreements are offered?

Patches, hot fixes and service packs are available to end users with valid maintenance agreements. Version upgrades are available to those end users with valid maintenance agreements or for a once off fee.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Support is covered under a paid annual support agreement and includes “virtual engineer” (desktop remoting), telephone, e-mail, online self-help tools, automatic driver updates, product upgrades, security advisory services, user forum and online knowledge base repository. On-site engineering may be added on as an additional service level agreement.

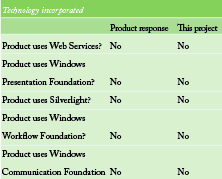

Technology incorporated

Management reporting and integration

Q: What native historical data reporting options are available?

Reports can be generated as either HTML or RTF files. The format of these files may be defined using any standard ASCII editor such as Notepad.

Q: What product specific interface does the product have iro well-known MES packages?

Citect provides free OPC Servers v1.0 and v2.0. In addition an OLE-DB compliant interface is available, as well as the Citect API for integration into higher level business systems. However, no certified MES interfaces are available.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

None.

Security and data protection

Q: What authentication, authorisation and role management models are available for the runtime environment?

Citect implements its own security model based on Areas, Privileges, Roles and Users. Security may be incorporated in the application or through Windows integrated authentication.

Area: A section of the plant (may be defined geographically or logically).

Privilege: A level of access applied to system elements within a project.

Role: A defined sets of permissions (privileges and areas) that is assigned to users.

User: A person or group of persons that need access to the runtime system.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

Integrated Process Analyst Tool – Productivity is increased via analysis of processes used to improve plant and production efficiencies.

Scalable – Allows system architecture to grow with changing requirements, while preserving initial investment.

Reliable – Citect’s redundancy will tolerate failure anywhere in the system, with no loss of functionality or performance.

Open Architecture – A collection of over 150 protocol drivers and Citect’s open connectivity from various information systems allows seamless data flow.

Integration of Schneider Electric automation products – The inclusion of tools such as the Pelco ActiveX, Webgate ActiveX, Magelis Diag Buffer and Speedlink within the standard software bundle at no additional cost reduces engineering time and ensures all components are able to communicate seamlessly.

| Tel: | +27 11 254 6400 |

| Email: | [email protected] |

| www: | www.se.com/za/en/ |

| Articles: | More information and articles about Schneider Electric South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved