End-user details

N/A

SI details

Name: Erie Pretorius

Designation: Director/owner

Company: Process Dynamics

Phone: +27 (0)11 394 5412

E-mail: [email protected]

Product details

Product name and version: WinCC V7.0 SP3

Vendor: Siemens

Phone: +27 (0)11 652 2000

E-mail: [email protected]

URL: www.siemens.com

Application details

Location: Wadeville, Gauteng

Industry: Food & Beverage

Application: Manufacturing

Server OS: N/A

Client OS: N/A

Application statistics

Tag count: 1000

Updates per day: 6 912 000

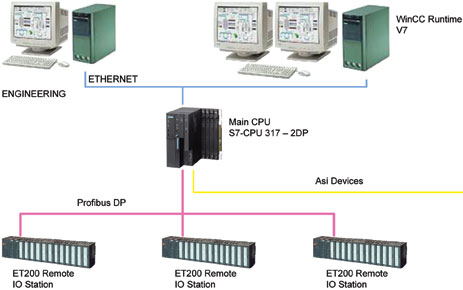

Front ends: 400 I/O across 3 remote I/O drops from one SIEMENS PLC S7-300 controller

Licences: WinCC V7.0 Runtime

End–user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

Scada for a new juice manufacturing plant for Coca-Cola, Wadeville.

Q: What was the primary motivation for the project?

To support a new manufacturing plant.

Q: What were the main goals established for the project?

N/A.

Licensing, maintenance & support

Q: What upgrade agreements are in place for this application?

None.

Q: How is the after-sales support handled on this particular application?

N/A.

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

No. It is standalone.

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

No.

Management reporting and integration

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

Yes. It uses WinCC archiving which is based on MS SQL.

Q: Is the system integrated with an MES/ERP or other management reporting or control system? (e.g. Baan, SAP, SYSPRO…)

No.

Q: Have any production benchmarking tools been configured as part of the scada system?

No.

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

No.

Q: Are you currently using tablet PCs or mobile phones to interact with the scada system?

No.

End-user conclusion

Q: In the procurement decision making process was the Total Cost of Ownership (TCO) considered? If so, what were the primary TCO considerations that influenced the product selection?

N/A.

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Support.

Q: What single feature most impresses you about the product now that it is in operation?

The integration with SIEMENS S7 PLC.

Q: What impresses you most about the architecture?

It is based on open standards and has standard drivers built in to the base system even for third-party systems.

SI Responses

Project details

Q: Approximately how many man-hours did the scada configuration take?

96 man-hours.

Q: What human factors were taken into consideration in the HMI design process?

None.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Standard library.

Q: How would you describe the library of graphic images?

Comprehensive.

Q: Did you use any ‘special’ images (e.g. photographs, 3D images, specialised dashboards, etc.)?

N/A.

Q: Did you use any video or multimedia technology used in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system?

N/A.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

N/A.

Q: What are the key physical communication layers and communication protocols employed in the system?

Ethernet, Profibus and AS-i bus.

Q: What levels of redundancy are incorporated in this scada application?

None.

Q: What specific custom code or scada scripts were written for this project?

N/A.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

Standard Windows based authorisation system is incorporated into the base system.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks?

N/A.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

N/A.

Q: What configuration backup and data archive backup methodologies have been adopted?

N/A.

Q: Did you use any integrated or third-party con-figuration control system for the scada configuration during the engineering of this application?

No.

SI conclusion

Q: How would you rate the ease of use of the historical reporting system?

Very easy to configure.

Q: What impresses you the most about the engineering/configuration aspects of the product now that it is in operation?

Ease of integration and ease of use.

Q: What impresses you most about the architecture?

It can scale from a stand-alone system to a multi server client application with ease.

Vendor responses

Product

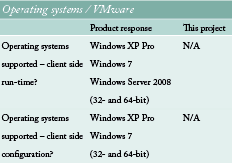

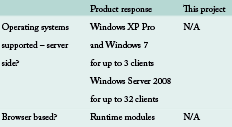

Operating systems/VMware

Licensing, maintenance & support model

Q: What sort of licensing agreement options are offered?

The base system includes Archiving. Add-ons and options are separate (e.g. Energy Management suite).

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Sold outright.

Q: What upgrade agreements are offered?

Patches and Service Pack are free and version changes are paid. An annual software update service, which includes all upgrades and version changes for a calendar year, can be purchased. The support policy is that the current version and one version back will be supported.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Service support is done via SIs or Siemens’s own support base.

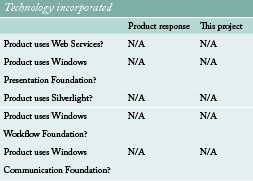

Technology incorporated

Management reporting and integration

Q: What native historical data reporting options are available?

MS Reporting Services are included as part of MS SQL.

Q: What product specific interface does the product have iro well-known MES packages?

Interfaces are available for most known MES systems such as SAP.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

WinCC integrates fully with Simatic Manager (Step 7 for the Siemens PLC). Tags are directly available and alarming is automatically generated during compile.

Security and data protection

Q: If the scada system generates application files that are transferred to the PLC, how are Stuxnet style PLC virus attacks prevented?

The scada system does not generate application files, only Simatic Manager does that. Stuxnet was a very specific virus for a very specific application. Preventative measures have been taken to prevent future problems.

Q: What authentication, authorisation & role management models are available for the runtime environment?

Incorporated in the application based on the Windows Authentication system.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

* Archiving system built in – No need for a separate archiving module.

* Integration into Step 7 – Alarming automatically generated.

* Fully integrated PLC and scada from one vendor – Embodies advanced features such as enhanced diagnostics.

| Tel: | +27 11 652 2000 |

| Email: | [email protected] |

| www: | www.siemens.co.za |

| Articles: | More information and articles about Siemens South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved