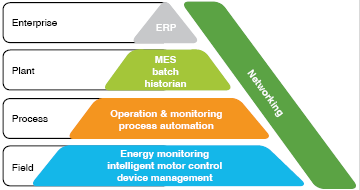

The PlantStruxure pyramid provides high availability solutions in real-time.

“High availability is required by all manufacturers whose environment cannot afford unexpected downtime because product material costs or operational start-up costs are high, aggressive production targets must be met, product quality is affected by downtime, and unscheduled downtime could potentially cause harm to people or equipment,” states the ARC research group’s white paper on Schneider Electric’s PlantStruxure architecture.

To combat downtime, PlantStruxure offers tested and proven high availability systems at every process level, focused on providing continuous operations, accelerating the process end user’s return on investment and increasing plant maintainability and efficiency.

“The increased efficiency in production systems that is gained through the monitoring and control features of PlantStruxure means higher productivity, lower costs and increased profitability for a business,” says Steve Gerber, product manager for automation at Schneider Electric South Africa. “This is because PlantStruxure industrial communication solutions enable clients to prioritise, act on and operate their processes more efficiently. It is a collaborative system that allows industrial and infrastructure companies to meet their automation needs and, at the same time, delivers on growing energy management requirements.

“In order to make smarter decisions, PlantStruxure enables operators to visualise the state of the plant from any location, assisting them to prioritise actions from the available information and respond in real-time for more effective process control. In a single environment, energy and process data can be analysed and used to optimise the plant holistically.”

The cause of process upsets can be analysed quickly and easily via Process Analyst features within the architecture’s dedicated configuration software, Vijeo Citect, allowing users to combine alarm and trend data in one integrated display for faster analysis.

“Vijeo Citect is scalable and has powerful visualisation capabilities and operational features. Delivering actionable insight fast enables operators to respond quickly to process disturbances for increased effectiveness,” says Gerber.

He adds that when analysing the cause of process disturbances or when trying to improve productivity in the process, the comparison of alarm and trend data is essential. While sophisticated analysis tools are available in data historians, Process Analyst is unique because it is an intuitive process analysis tool that sits directly in the system. It delivers actionable insight to the user and gives the ability to modify process conditions immediately to achieve the desired results.

PlantStruxure also allows users to save preconfigured and ‘favourite’ views within Process Analyst in order to make it easy to access the information needed to improve efficiency and productivity.

“Trends are a seamless combination of real-time and historical data. When users display a trend page, they can monitor the current activity as it happens and simply scroll back through time to view the historical trend. An efficient alarm system allows users to isolate and identify faults quickly within the system or process, thereby reducing plant downtime,” says Gerber.

The PlantStruxure alarm system is fast and reliable, providing users with detailed information about the status of the plant. Alarms are displayed on dedicated alarm pages, with the most recent alarms visible at all times in the alarm banner on every page. Working in conjunction with the controller or RTU, alarms are time-stamped with precision, essential when differentiating between alarms that occur in rapid succession.

The ability to extend plant operations from the control room to the plant floor is important and PlantStruxure supports dedicated plant floor HMIs built to withstand the rigours of industrial environments. The ruggedised features and flexible options of the Magelis range make them perfect for use in plant floor cabinets and other specialised applications.

In addition, integrating Pelco cameras into the PlantStruxure architecture allows live video to be viewed within system. Users are able to control these cameras, enhancing real-time process visibility or integrating remote security monitoring.

“The architecture’s mobility solutions give users the freedom to observe operations firsthand, wherever they are, by providing easy access to the process from dedicated Web clients or smart mobile devices such as PDAs or mobile phones. This increased visibility into real-time processes helps users make more effective decisions, resulting in greater flexibility, decreased downtime, increased plant productivity and a lower total cost of ownership,” concludes Gerber.

For more information contact Jacqui Gradwell, Schneider Electric SA, +27 (0)11 254 6400, [email protected], www.schneider-electric.com

| Tel: | +27 11 254 6400 |

| Email: | [email protected] |

| www: | www.se.com/za/en/ |

| Articles: | More information and articles about Schneider Electric South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved