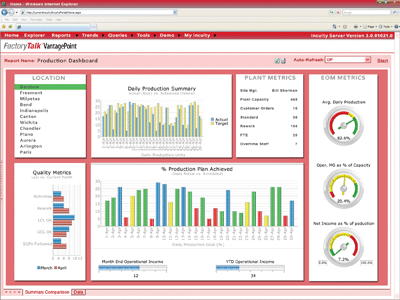

VantagePoint – an application for web-based reporting of plant floor data.

Rockwell Automation has announced the launch of Rockwell Software FactoryTalk VantagePoint, an application for web-based reporting of plant floor data. The new application is an innovative addition to Rockwell Automation’s FactoryTalk Integrated Production and Performance Suite that allows end users to self-configure rich Web-based dashboards, trends and reports without expensive, time-consuming support resources.

FactoryTalk VantagePoint software leverages the FactoryTalk service-oriented architecture and technology acquired through the company’s purchase of Incuity Software to deliver automatic access to valuable production information from both Rockwell and third-party systems in an easy to use, cost effective manner.

Through an Internet browser, Microsoft Office user interfaces and pre-defined connectors to third party systems, FactoryTalk VantagePoint users can install and configure their systems in as little as a few hours with minimal technical support. This immediate access to actionable insight allows employees at every level of a production facility to better monitor and manage productivity, and exercise more control over operations such as energy efficiency or global supply chain execution.

Providing cohesive access to information on demand in an intuitive format improves decision support in many aspects of the manufacturing environment – from inventory to maintenance, production to quality, and up through the enterprise and supply chain planning.

In a 2008 report, AMR Research highlighted the value of integrating Incuity technology into the FactoryTalk suite. “IncuityEMI provides an extremely flexible, extensible, data-modelling framework that is designed to capture and maintain complex relationships between a virtually unconstrained set of data sources,” the report says. “In fact, you can find IncuityEMI today in oil and gas, energy management, food production, and facilities asset management scenarios. There, it is contextualising data from ERP, MES, LIMS and CMMS systems along with time series data from historians like OSIsoft’s PI and AspenTech’s IP.21, and, in many cases, doing this across multiple facilities.”

The VantagePoint application will be offered in multiple versions, allowing manufacturers to select the most appropriate feature set for their needs. The first version, FactoryTalk VantagePoint Line Edition (LE), combines data produced by the Rockwell Automation Integrated Architecture with other third-party production systems in an easily configured and installed out-of-the-box solution. It includes standard, pre-configured reports for managing devices, equipment, alarms, events and control loops, as well as batch or production run and shift reports. The application also includes trending and dashboard capabilities to support powerful analysis and uses Microsoft Excel for easier report generation.

In addition to gathering data from control systems based on the Rockwell Automation Integrated Architecture, the application features third-party connectors that address native and OPC DA real-time devices, OPC HDA historians, as well as Wonderware IndustrialSQL Server Historian, GE Proficy Historian and OSI PI Historian.

Rockwell will soon be releasing FactoryTalk VantagePoint Enterprise Edition, a more comprehensive version designed to aggregate and analyse data from multiple enterprise systems, production lines or facilities.

The FactoryTalk VantagePoint application is the latest addition to the comprehensive line of existing performance and visibility applications already available with the FactoryTalk Integrated Production and Performance Suite. The software suite delivers comprehensive business benefits across six production disciplines common to most manufacturing operations. These scalable applications are designed for tight integration with the Rockwell Automation Logix Control Platform, as well as extensive connectivity to third-party and legacy systems.

For more information contact Sean Homan, Rockwell Automation, +27 (0)11 654 9700, [email protected], www.rockwellautomation.co.za

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved