Operating safely

September 2009

Fieldbus & Industrial Networking

Fibre-optic fieldbus systems in oil production.

Hirschmann networks recently developed oilfields in the United Arab Emirates with highly available fibre-optic fieldbuses.

Production has recently started at two new oilfields 50 km southwest of Abu Dhabi city, Rumaitha in the countries interior and Al Dabb’iya on the coast. The daily production capacity of the fields is about 100 000 barrels. The facilities for producing, storing and metering the crude oil have been in operation since late 2005. Operating safety is paramount here, so the process control system has been designed with full redundancy, and data is transmitted between the controllers and the remote I/O stations via fail-safe, redundant optical fibres. The danger of explosion that is inherent in such facilities presents a particular challenge. This challenge must be met with ATEX approved devices that are also capable of withstanding high ambient temperatures.

Project details

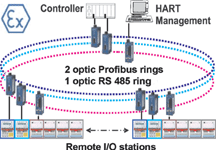

The process control is designed as a redundant system to specifically meet the customer’s demand for high process data availability. The process control units constructed by Honeywell provide a primary and a secondary Profibus DP interface with the remote I/O stations. HART information is recorded via an independent service bus using an RS485 interface. Optical cables and redundant optical rings ensure an exceptionally high level of operating safety. The cabinets, installed in explosion protection zone 2, include devices for properly isolating the intrinsically safe signals that are primarily used here for transmitting to zone 1 and zone 0. The power supplies for the remote I/O stations are designed redundantly. The cabinets have been engineered to prevent heat accumulation and they are also equipped with solar protection means. Otherwise, it would not be possible to keep the electronic components in the cabinet sufficiently cool in desert conditions.

Project parameters

* Profibus DP and HART communication.

* 15 km transmission length.

* 2600 process signals.

* 72 remote I/O stations.

* 176 OZD Profi 12M G12.

* 26 OZD Profi 12M G12-1300.

* 88 OZD 485 G12.

* 13 OZD 485 G12-1300.

Requirements

* High availability of the process control system.

* 85°C solar temperature.

* 52°C air temperature.

* 95% maximum air humidity.

* Explosion protection zones 2 and 1.

Solution

* Redundant control stations with two Profibus interfaces.

* Redundant communication via optical Profibus DP rings.

* Communication with HART management system.

* Switch cabinet designed for high operating temperature.

* Devices ATEX-approved.

Why Hirschmann

* Fibre-optic converter for Profibus DP.

* Fibre-optic converter for HART via RS485.

* Designs for long and medium segments.

* Redundancy with optical rings.

* ATEX approvals received.

For more information contact Profitek, +27 (0)12 664 4998, [email protected], www.profiteksa.com

Further reading:

Integrating fire alarm systems into building management systems

Beckhoff Automation

Fieldbus & Industrial Networking

Fire alarm systems work independently of the building automation system. Schrack Seconet has developed a flexible gateway using ultra-compact industrial PCs and TwinCAT from Beckhoff, which can be used to flexibly convert a customer-specific communication protocol to a wide range of transmission standards.

Read more...

Premium unmanaged industrial switch

Vepac Electronics

Fieldbus & Industrial Networking

Premium unmanaged industrial switch for long-distance, noise-free fibre connectivity

Read more...

Fire and gas suppression solutions for mission-critical industries

Fieldbus & Industrial Networking

By representing world-leading brands and focusing on fully integrated, certified systems, HMA South Africa is positioning itself as a trusted partner in fire detection, suppression and explosion-proof safety solutions across the continent.

Read more...

The future of manufacturing

Fieldbus & Industrial Networking

Industrial automation is evolving at an unprecedented pace. At the forefront of this transformation is the Siemens SIMATIC ET 200SP HA Distributed I/O system. This is a flexible and scalable distributed I/O system for modern signal transfer from the field to the control level.

Read more...

Time-sensitive networking

RJ Connect

Editor's Choice Fieldbus & Industrial Networking

In this article, we will explore what is driving the rise of time-sensitive networking, how it is reshaping industrial efficiency, the challenges when deploying this technology, and ways to tackle these challenges.

Read more...

Loop Signature 30: Nonlinearity in control loops (Part 1)

Michael Brown Control Engineering

Editor's Choice Fieldbus & Industrial Networking

If nonlinearity occurs it means that if one is to carry on controlling with the same response to changes in load or setpoint, then the tuning of the controller will also need to be adjusted to meet the new conditions.

Read more...

PC-based control regulates innovative dehumidifiers

Beckhoff Automation

Fieldbus & Industrial Networking

Swedish company, Airwatergreen is breaking new ground in the dehumidification of air in industrial buildings and warehouses. The patented CVP technology reduces energy requirements and ensures an indoor climate that prevents corrosion and mould growth. PC-based control from Beckhoff regulates this innovative process.

Read more...

Ethernet connectivity for embedded systems

Fieldbus & Industrial Networking

Delivering Ethernet connectivity for embedded systems, XPort ETH Click is a compact add-on board from MIKROE, the embedded solutions company that dramatically cuts development time by providing innovative hardware and software products based on proven standards.

Read more...

Compact mini PC

Vepac Electronics

Fieldbus & Industrial Networking

AS AAEON’s first Intel Core-powered PICO-SEMI system capable of fanless operation, the PICO-MTU4-SEMI from Vepac Electronics is easily deployed as part of larger equipment setups or integrated as the central unit of smart robotics solutions such as AGVs, AMRs and drones requiring minimal maintenance.

Read more...

Future-ready I/O to redefine connectivity

Schneider Electric South Africa

Fieldbus & Industrial Networking

Schneider Electric South Africa has launched its state-of-the-art Modicon Edge I/O NTS. This future-ready I/O redefines connectivity, data aggregation and operational efficiency for industrial applications.

Read more...