Several terms are used in reference to the measurement of disinfecting parameters. However, total, free, bonded, residual, compound and radical chlorine are all in effect interrelated and play a vital role in disinfection. Endress+Hauser offers an array of tools for complete chlorine measurement and analysis.

Total chlorine refers to the total amount of chlorine which includes both free and combined chlorine. Free, residual and radical chlorine all refer to unbound chlorine, the driving force in disinfection - all these parameters are one and the same thing. A cause for confusion is the fact that hypochlorous acid and hypochlorite ions exist together in equilibrium based on the pH value. In effect, hypochlorous acid dissociates into hydrogen ions and hypochlorite ions.

Disinfection is offered by the hypochlorous acid. As the pH value increases, so the disinfecting capabilities of the hypochlorous acid decrease. At pH6, there is a 97% composition of hypochlorous acid. At pH9, this composition decreases to 3%. A practical example is that of a home swimming pool. If the pH value of the pool is not lowered, large amounts of chlorine additions will achieve minimal disinfection results.

In terms of bonded and compound chlorine, there are often applications where potable water needs to cover long distances to reach the consumers. As residual chlorine dissipates from solution over time, water authorities often use a carrier medium in order to protect the chlorine for prolonged release. This ensures continued disinfection throughout the piping distance. Bonded chlorine is also less sensitive to pH variations and is stable in that respect. However, measurement is made difficult since the bond must be broken first before measurement can take place.

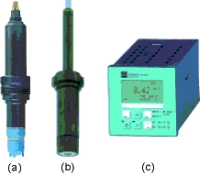

Endress+Hauser offers tools to measure both residual chlorine and total chlorine. Bonded chlorine cannot be measured independently from the residual chlorine. In order to obtain the bonded chlorine value, the residual chlorine value is subtracted from the total chlorine value. Endress+Hauser offers the CCS140/141 sensor for residual chlorine and the CCS120 sensor for total chlorine. (In addition, chlorine dioxide can also be measured with the CCS240/241, but this is not discussed in this article.) All three sensor types can function with Liquisys M Chlorine transmitter and a range of products are available to augment this transmitter.

The CCS140/141 determines the concentration of chlorine according to the amperometric measuring principle. The membrane capped sensors consist of a cathode serving as the working electrode and an anode acting as the counter electrode. These electrodes are immersed in an electrolyte.

The hypochlorous acid contained in the medium diffuses through the sensor membrane and is reduced to chloride ions (Cl-) on the gold cathode. On the silver anode, sliver is oxidised to silver chloride. The electron release of the gold cathode and electron acceptance on the silver anode result in a current flow which is proportional to the free chlorine concentration in the medium under constant conditions. The concentration of hypochlorous acid in the medium depends on the pH value. This dependence can be compensated by measuring the pH value in the flow assembly. The transmitter transforms the current signal into the measuring unit concentration in mg/l.

Endress+Hauser's CCS140 and 141 sensors measure free chlorine using the internationally accepted DPD method. A photometer with the pertaining reagents is required. The determined value is the calibration value for the transmitter.

Although similar in measuring principle and function, the CCS140 is suitable for applications with a measuring range of 0,05 to 20 mg Cl2/l (ppm), while the CCS141 sensor is especially suitable for disinfection of drinking water conditioning or for the detection of chlorine traces with a measuring range of 0,01 to 5 mg Cl2/l (ppm).

Used for the continuous measurement of total chlorine, Endress+Hauser's CCS120 sensor, also a membrane capped amperometric sensor, is based on the conversion of the measured variable to electrical current. Two electrodes covered by an electrolyte are in contact to the medium via a membrane. It has a platinum working electrode and a silver halogenide coated counter or reference electrode. The chlorine compounds contained in the medium diffuse through the membrane.

The constant polarisation voltage between the two electrodes instigates the electrochemical reaction of the chlorine compounds on the working electrode. The resulting current is measured as a primary signal and is proportional to the chlorine concentration within the sensor's operating range. This sensor is only slightly dependent on pH value. The primary signal is converted by the amplifier electronics of the sensors into a 0 ... 5 µA output signal which is displayed by the transmitter.

Total chlorine consists of free chlorine (HOCl, OCl-) and bound chloride (chloramides). To calibrate the measuring system, the content of chlorine is determined using the DPD 4 method. In order to do so, a photometer with the pertaining reagents is required. The determined value is the calibration value for the transmitter.

For more information contact Chantel Maree, Endress+Hauser, 011 262 8000, [email protected]

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved