As Ethernet has become more and more important in the office world, some users and vendors are investigating the possibility of using an open network system for automation applications within factories. However, as full reliability and a high realtime capability are the most important functions in factory automation, it is almost impossible to use standard Ethernet on the factory floor. The result of this is that fieldbus systems are normally used at the factory floor level and (proprietary) Ethernet networks are used in the office level.

Recently, however, some users and vendors have reported productivity improvements through the use of Ethernet. That means that users want to use Ethernet as an open and flexible network to connect various kinds of devices within their factories, even at the factory floor level. Profinet, the realtime Ethernet solution based on Industrial Ethernet, was introduced by the Profibus Nutzerorganisation (hereafter PNO) in 2000 and is based on the IEC61158 and IEC 61784 standards. The PNO is presently developing further Profinet features with 80 engineers from over 50 companies.

The fact that Profinet permits the simultaneous use of realtime communication and IT standard communication (TCP/IP) on the same network - without limitations - means that it is well suited for communication at all factory levels.

In February this year (2004), the Japanese Profibus Organization (hereafter JPO) announced that a Profinet Working Group was set up. The purpose of this working group is 'to investigate the possibility of using Ethernet as a Factory Network', and 'to exchange the information on realtime Ethernet between Europe and Japan'. The PNO officially approved this working group in March 2004.

The main goal of this working group is to consider the requirements of the Japanese market with regards to Profinet. The establishment of an open and flexible factory network system in the automation world can improve factory management, increase efficiency and reduce costs. Over the last three years JPO has introduced Profinet into the Japanese market by means of seminars and demonstrations. Last year (2003) JPO held Profinet demonstrations at several exhibitions and at a realtime seminar in July. There was a very positive feedback from all attendees.

The working group includes, among others, HMS Industrial Networks, M-System, Omron Corporation, Siemens, Toshiba, Hilscher, Fuji Electric Advanced Technology, Yaskawa Siemens Automation & Drives and Yokogawa Electric.

These top Japanese and European automation companies are in a position to competently discuss this topic. The working group will spend two years investigating industrial realtime Ethernet based on Profinet from the point of view of specification, engineering, maintenance, life cycle, system responsibility, etc.

The working group will have permanent contact with the Profinet working groups in Europe, as these have more experience in industrial Ethernet, and will continue to work on new topics such as security, Web integration and so on. JPO chairman, Shinichi Motoyoshi, believes that "the strong membership of the working group will lead to new trends being set in industrial realtime Ethernet and help make them a reality." JPO will ask other users and vendors, who are interested in a Profinet solution to participate in the working group.

Integrating Interbus with Profinet

In March this year Profibus International has set up another working group called 'Integration of Interbus' to facilitate the integration of Interbus fieldbus technology and Profinet.

The working group is preparing a specification that will adapt the Profinet 'proxy' concept to allow the integration of Interbus systems into Profinet architectures. The specification will also include the required engineering. A draft specification is expected to be completed by the end of this month (September 2004). The working group consists of specialists from Profibus International and the Interbus Club. The Chairman is Dr Jürgen Jasperneite of Phoenix Contact.

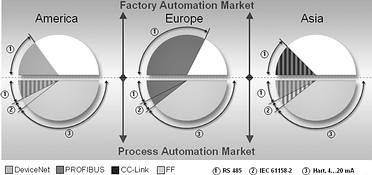

The proxy solution allows Interbus users to easily benefit from the next-generation Ethernet-based automation strategies offered by Profinet. It provides a secure investment protection path for Interbus users. With respectively 10 million and 6,5 million nodes Profibus and Interbus have the highest installed basis of all fieldbus solutions. Markets experts are therefore expecting Profinet to be the market leader for Ethernet-based automation systems in the future.

For more information contact Profibus International Support Centre, 0949 721 96 58 5 90, [email protected], www.profibus.com

© Technews Publishing (Pty) Ltd | All Rights Reserved