Power generating plants have traditionally used many ‘systems’ to control their processes even after the DCS was embraced by the industry as the control system platform.

Typically, one would find the following different systems in a power plant:

* Dedicated OEM supplied systems (PLCs) from steam/gas turbine vendors.

* Plant-wide DCS.

* Electrical control and monitoring system (ECMS).

* Dedicated burner management (BMS) and boiler protection systems (BPS), often based on a SIL 3 rated safety system.

* Various PLCs for different ‘packaged’ systems.

However, such a wide variety of platforms was always a matter of inconvenience for the plant operation and maintenance crew. The following difficulties were faced by the plant O&M team:

* Non uniform HMIs, leading to difficulty in switching from one mode to another while operating the plant – especially during critical plant conditions.

* Difficulty in asset management of instrumentation and control as well as increased inventory of spares for the different systems.

* Complicated training needs for both maintenance and operation.

To circumvent this, many power generation companies would select the control system over the turbine supplier, so as to keep the control system ‘uniform’ at least for a part of the plant. However, very soon, everybody realised that this resulted in a very narrow choice of control system platform, which was not always the best on techno-commercial merit. It was soon recognised that an important component of the plant, the control system (DCS), was piggybacking on the turbine systems under these situations.

The industrial automation industry has always been receptive to the aspirations of users and has tried to bridge the gap between the needs of the industry and the solution. As a result, the DCS vendors consciously developed solutions to cater for the need of an integrated control system platform that provided the same look and feel across applications. The focus was on:

* Uniformity of platform.

* Common HMI.

* Common engineering station.

* Common network without the need of gateways.

* Basic hardware commonality in terms of form factor, power requirement etc.

* Compliance to industry standards.

* Improved equipment reliability, plant availability and ease of use.

* Improved plant safety.

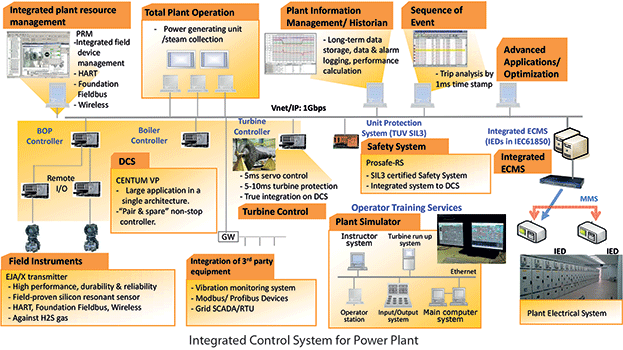

As a leading DCS vendor, Yokogawa has strived to lead this effort and bring to the table an integrated platform for power generation plants. In review, this is how the features of Yokogawa’s Centum VP DCS have been designed to achieve convergence.

Organisation of the control system

Boiler/HRSG (heat recovery steam generator) and BOP (balance of plant) control

This is the core of the control system (DCS) with the majority of I/O modules and controllers, which run the interlocks, sequences and closed loop control system. These various analog I/Os are typically equipped with HART pass through function to enable integrated asset management (Yokogawa’s PRM: Plant resource Manager) for smart devices. Very often, digital fieldbus technologies such as Foundation, Profibus or wireless technology (ISA 100.11a) are adopted, which is an integrated feature of the DCS. Redundancy at all levels, including redundant I/O modules, is often used to increase the reliability and availability of the control system.

BMS (burner management system) and BPS (boiler protection system)

Often, many conventional DCSs are extended for BMS and BPS functionalities. The NFPA 85 guideline insists on independently working hardware for BMS/BPS. This is achieved by separate sets of I/O modules and controllers and independent sensors in the field. However, in many cases, as per the HAZOP study recommendation, this is identified as an area where Safety Instrumented System (SIS) with a requirement of SIL 3 should be used. In that case, a certified SIL 3 safety system is recommended with an SIS logic solver/safety PLC.

Conventionally, two separate monitoring and operating environments were required for the DCS and SIS. Different communications and distinctive hardware architectures had to be set up. Yokogawa put an end to DCS-SIS incompatibility with the ProSafe-RS, a truly integrated safety PLC for the process industry.

ProSafe RS (TUV SIL 3 certified) safety PLC and Centum VP DCS are tightly integrated with Yokogawa’s dual redundant, 1 Gbps Vnet/IP DCS network.

Turbine governor control and protection

Turbine control and protection for governors requires very fast control and many special types of inputs and outputs; e.g. direct speed pick-up from magnetic/active pick-ups, servo drive, LVDT measurement etc. Special I/O modules have been developed which have these capabilities. These special purpose modules have the same form factor and configuration as other conventional I/O modules, and are supported by advanced features like 1 msec SOE and module redundancy. They use the same DCS controller and I/O bus as a backbone. Thus the turbine governor control and protection (over speed, power imbalance etc.) is truly integrated in the plant DCS. This solution is deployed in many retrofit projects.

Integrated 1 msec SOE

An SOE (sequence of events) with 1 msec accuracy and resolution is an important feature in a power plant DCS. Yokogawa’s Centum VP system design allows all DI (digital input) modules to have this capability and selectively assign DI channels for SOE reporting. The special purpose turbo machinery cards also have DI channels with 1 msec SOE. Similarly, DI cards for safety systems also have 1 msec capability. This is a very important tool for diagnostics of plant upsets and helps tremendously when performing root cause analysis investigations.

CAMS (consolidated alarm management software)

CAMS for HIS (human interface station) is consolidated alarm management software that is included at no additional cost. It acquires real-time alarms and events from various systems, and then sorts and delivers only the necessary alarms to the right person at the right time. This type of alarm sorting enables users to identify the root cause of alarm or trip occurrences. Alarms and events are displayed with their original time stamping, up to a millisecond, even when acquired from third-party systems through interfaces like OPC A&E, IEC 61850 etc.

The EEMUA 191 guidelines are followed in the software design and the following advanced alarm management features like prioritisation, suppression, eclipsing, sorting, filtering, shelving, load shedding etc. are available. These capabilities, along with plant-wide alarm reporting and analysis in a consolidated window, are a major achievement towards convergence and consolidation of the control system platform for a power generation plant.

ECMS (electrical control and monitoring system)

Traditionally, power generation plants had a separate electrical scada system to cater for the control and monitoring of HV/MV/LV electrical boards and systems. However, thanks to the standardisation of matured digital communication protocols like IEC 61850, a modern DCS has the capability of directly communicating with the IEDs (Intelligent electric devices) of an electrical system. This allows fast, bi-directional communication with the electrical system from and to the DCS. Thus, a separate electrical scada became superfluous.

MMS (manufacturing message specification) is a communication protocol for control and monitoring among industrial automation devices and systems. MMS is adopted as one of the protocols for communications among IEC 61850 IEDs. The DCS communicates with IEDs using the MMS service protocol.

The biggest advantage of an integrated control, safety and electrical system is the ease of operation by the plant operators. They get the same HMI to operate the entire plant and all plant-related data, alarms or messages are made available in a single platform. This can be achieved without compromising the advanced features of a modern DCS using state-of-the-art technology.

Third-party system integration through open protocols (especially OPC)

Practically, there are control systems beyond the plant-wide DCS, which are typically delivered by OEMs e.g. turbine control systems for new plants, PLCs from packaged systems etc. Thanks to OPC connectivity (both OPC DA and OPC A&E) these control systems can be seamlessly integrated with the plant DCS. Most importantly, it is possible to capture alarms and events with their original time stamp. This is a big benefit to the plant O&M team trying to increase plant productivity, and assists with analysing plant abnormalities and trips from a single platform.

Conclusion

Convergence of control system platforms is a big productivity enhancement tool for plant O&M management today. Further applications of plant performance monitoring and optimisation using advanced process controls, such as Exapilot to ensure repeatability, can easily be built on the plant-wide DCS, which is integrated in nature. Worldwide, Yokogawa is currently delivering many projects with these features.

The industry is excited about control system convergence. Power generation companies are showing an increased inclination to buy a modern DCS from the open market with such capabilities. As a market leader in DCS technology, Yokogawa is striving to match the aspirations of power plant owners and operators.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved