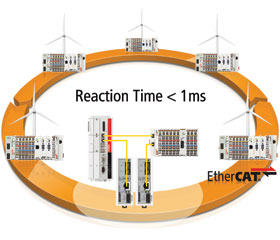

The expansion of renewable energies is rapidly gathering pace worldwide. The need to reduce carbon emissions, as well as a decreasing acceptance of nuclear power, are both contributors to this development. Since wind and sunlight are not constantly available, however, feeding the renewable energies into the grids can lead to problems that are not insignificant. The fast EtherCAT-based automation solution from Beckhoff enables reaction times of less than 1 ms.

The early diagnosis of voltage drops increases grid compatibility. In addition to wind turbines, this technology is also suitable for use with solar farms.

Initial steps have already been taken in this direction: many international grid connection regulations – the so-called Grid Codes – now prescribe LVRT capability (low voltage ride through) for every wind turbine. This means that, in the case of sudden changes of voltage in the grid due to short circuits for example, the plant must remain connected for a defined period of time, and must feed in defined reactive currents for fault-finding and to support the voltage. Subsequently, it must return within a few seconds to full active power feed-in. The demanded reactive currents depend on the depth of the voltage drop and must be applied, depending on the requirement, at the wind turbine or at the grid connection point.

On this basis, every modern wind turbine is today able to react appropriately to a voltage drop in the grid. Wind farms are becoming increasingly large and installations of up to 500 MW are no longer a rarity. In view of the size of the internal power networks in the wind farm, LVRT conditioning executed purely at turbine level at the grid connection point often does not produce the effect desired by the grid operator. Due to the impedances lying between them, the voltages differ between the turbines and the grid connection point. This means that each wind turbine reacts differently to the changes in the grid. Also, the reactive currents fed in at turbine level are not identical to the resulting reactive current at the grid connection point.

The Beckhoff solution is designed to deal with this problem and enable a coordinated reaction of the entire wind farm to a voltage drop in the grid. In this way, the solution achieves a defined behaviour of the entire farm at the grid connection point.

So far the following values have been regulated for the feed-in of wind turbines or wind farms:

• LVRT and local voltage limitation (temporal requirement of the control time: 10-20 ms).

• Active power as well as reactive power or voltage (temporal requirement of the control time: 1-60 s).

Due to the temporal requirements, the reaction in the LVRT case is presently realised at the turbine level in the converter. The delays in the control loop which occur due to centralised conditioning by a farm controller would hamper the attainment of the demanded dynamics.

The voltage/reactive power level is realised at the wind farm level; only in this way can a set point value specified for the grid connection point also be achieved there. In conjunction with a weak grid connection and a Q(U)-characteristic, the high dynamics (control time 1 s) sometimes demanded represent a challenge here.

Wind farm networking with EtherCAT

The 2011 lecture by Melanie Hau and Martin Shan on the subject of 'Wind farm control for network integration' showed that the speed of the wind farm networking and that of the turbine automation fieldbus both exert a significant influence on the attainable dynamics in the control of the voltage or reactive power in a wind farm.

This is precisely the point of attack of the Beckhoff solution, which is based on wind farm networking using EtherCAT. Wind farm networking has so far been realised using Ethernet. Ethernet fibre optic cables are used for the connection of the individual wind turbines to the master computer. Since EtherCAT is based on Ethernet, and thus fully compatible with it, the same physics can be applied when using EtherCAT. The subject of cable redundancy is also fully solved with EtherCAT. The fibre optic cable ring in the wind farm is closed at the farm master. The necessary TCP/IP communication can take place via switch port terminals within the EtherCAT I/O system. The highlight here is that not only a significantly higher transmission rate is achieved by using EtherCAT, but also that significant cost benefits result in comparison with the redundancy-capable switches that have been used so far.

Power measurement at 10 000 samples/s

EtherCAT significantly increases system speed: A fully occupied EtherCAT telegram containing 1500 bytes can be sent by the master and received again in an impressive 77 s. Assuming a process image of 50 input bytes and 50 output bytes for each wind turbine, the process image of a wind farm with more than 150 wind turbines can be refreshed in less than one millisecond. If the speed requirements or the number of wind turbines should significantly increase, several EtherCAT rings can also be realised on one master.

In addition there are further new technologies realised with EtherCAT: for instance, oversampling functionality permits the measurement or the output of signals in the field with a frequency of up to 100 kHz. This oversampling technology is used, for example, for the measurement of the current and the voltage at the grid connection point with the aid of the EL3773 EtherCAT power measurement terminal. The sampling frequency here is 10 kHz.

The distributed clock function of an EtherCAT device, with a resolution of 1 ns and an accuracy of 10 ns, permits the temporal synchronisation of measured and control values in a time window significantly smaller than 1 s, since all distributed clocks in an EtherCAT topology are synchronised by propagation delay measurement. On the basis of this function, the measured values in a wind farm can be synchronised extremely accurately. Even the synchronisation of the IGBTs of converters within a wind farm can be achieved with this technology. To this end, both the turbine manufacturer and the converter supplier must be brought on board.

Wide range of applications due to open control technology

In summary, this means that, using available standard components, a wind farm controller can be realised that makes a defined reaction of the entire wind farm to a voltage drop in the grid possible, at the grid connection point. Outside the fault case, too, highly dynamic voltage or reactive power controllers can be implemented in the wind farm for weak grid connections.

Due to the openness of the EtherCAT system, this solution is possible with controllers from third-party vendors as well: master and slave interfaces for all common fieldbus systems are available for the EtherCAT terminal system. Serial protocols are available for most interfaces; communication can alternatively be accomplished with parallel wiring.

The EL3413 EtherCAT Power Measurement Terminal, which is equipped with a direct 690 volt connection, can be used on any wind turbine for checking the controller. Extra signals such as weather data can be collected simply and inexpensively via this topology.

In comparison with conventional IP solutions, wind farm networking with EtherCAT is faster and offers substantial cost benefits. The faster the farm networking is, the more effective the energy provider is able to react to voltage drops or changing grid requirements. The EtherCAT Power Measurement Terminal integrated in the automation system logs momentary current and voltage values at the feed-in point at up to 10 000 samples/s. Early diagnosis of voltage drops is thus guaranteed.

Unlike current alternative solutions, it is possible to generate the reaction of an entire wind farm to an LVRT case using EtherCAT. If a voltage drop is diagnosed at the feed-in point, this can be signalled to all turbines in the entire farm network within 1 ms. Via the EtherCAT distributed clocks, the measured values of all wind turbines and the measurement at the point of common coupling can be synchronised to a timeframe smaller than 1 s. With these data, the current, voltage and frequency can be controlled accordingly and the grid can be supported. The existing fibre optic-based Ethernet infrastructure can be used.

For more information contact Kenneth McPherson, Beckhoff Automation, +27 (0)11 795 2898, [email protected], www.beckhoff.co.za

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved