The FieldConnex temperature multi-input device (TM-I) from Pepperl+Fuchs highlights the ease and efficiency with which analog temperature input signals can be connected via fieldbus. Now, with the new diagnostic handheld (FDH-1), fieldbus installations are becoming even easier to operate. The mobile device checks any segment quickly and easily – all at the touch of a button.

Fieldbus process interfaces can bundle together multiple conventional input and output signals to incorporate them into digital communication in a very simple and highly efficient process. This setup can considerably reduce the amount of wiring required. For example, instead of the multi-core cable, a simple two-wire cable is all that is required. In terms of efficiency and ease of use, however, the number of terminals to be installed is an even more crucial factor. At least one allocation fewer is required per signal in this case, since this process takes place electronically in the control technology. This saves considerable costs associated with planning, wiring, documentation, and checking out the cable following installation.

Simple operation extended to hazardous areas

Instead of individual I/O connections in the control cabinet, the TM-I can be mounted in the immediate vicinity of the sensors, meaning that the amount of wiring required can be significantly reduced. All measured values from the TM-I are communicated digitally via a two-wire cable to the control room. In addition to thermocouples and millivolt signals, 2, 3, and 4-wire resistance temperature detectors (RTDs) can be connected in this way.

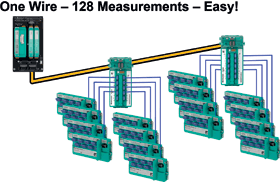

For example, it is possible to operate 16 TM-I devices on one fieldbus segment. In this case, this means a total of 128 temperature measurement sensors can be integrated via a few, short cable connections and a two-wire trunk – with only one connection to the TM-I and without any additional electrical allocation. This allows cable runs from 700 to 1000 metres in length to be installed from the control room to the junction box without any problems, including in hazardous areas. The inputs on the TM-I are quick and easy to configure collectively, and configuration on an individual basis is possible. The process for configuring and integrating the control technology is extremely convenient; these tasks are carried out using GSDs and FDT/DTM.

Since temperature measurements are often carried out in hazardous areas, explosion protection plays an important role. In the case of temperature measurements, this form of protection is usually achieved through mechanical ignition protection, Ex d/Ex e, or intrinsic safety. These methods allow sensors to be operated in every area up to Zone 0, Division 1. The TM-I offers users free choice of ignition protection class at each electrical connection. The inputs are certified as intrinsically safe if the fieldbus connections are protected mechanically and operated with high power. This allows maximum flexibility in project planning and implementation according to the user’s preferred standards for explosion protection. This setup is also supported by turnkey enclosure solutions.

Turnkey solutions for individual applications

For new systems, or for simply migrating systems from conventional connection technology to fieldbus technology, Pepperl+Fuchs offers users a range of preinstalled enclosure solutions for the TM-I, which are supplied ready for assembly, including the ignition protection. These prewired solutions include temperature multiplexers and junction boxes such as FieldBarriers or segment protectors. A host of different enclosures are available for users to choose from: Depending on the application requirements, customers can choose between space-saving, durable aluminium enclosures, stainless steel models, or lightweight, cost-effective solutions made from fiberglass. Individual cable glands are also available. Lightning protection and terminators are additional accessories that can be selected in the standard solution. As a special service, the company even provides the certification.

A mobile expert at your fingertips

To make it even easier to install and use the fieldbus infrastructure, Pepperl+Fuchs has developed a new diagnostic handheld (FDH-1). Using this mobile device, it is possible to check any segment quickly and easily. The handheld has been specifically designed so that it is easy to operate without expert knowledge. In fact, a single touch of a button is all that is needed to carry out an initial check. Before commissioning a segment, the device shows whether faults have crept into the fieldbus installation, where these faults are, and how to resolve them. This makes it possible to save time and costs when installing and maintaining the fieldbus infrastructure. Using the handheld, existing cables can be checked quickly and without any problems, to determine whether they can be used for a fieldbus installation. By taking this approach, savings can be made in terms of cabling costs and outlay, ensuring reliable operation.

In addition to installation and commissioning, the quality assurance process is greatly simplified by the handheld, since the device is extremely easy to use, even without expert knowledge. It works as a stand-alone solution that users without access to a PC can connect to any fieldbus segment to check in a one-click process. The device is as easy to use as a standard multimeter, but offers many more functions. For example, the handheld is equipped with an integrated expert system that interprets the measured values and detects any faults that may be present, specifying how to fix them. What’s more, a commissioning wizard with guided dialogues ensures the handheld is easy to use and produces documentation in a format that is ready to file.

Fieldbus installations not only enable very efficient connection: Using the mobile handheld, the fieldbus is also much easier to operate, providing the ideal basis for trouble-free operation and maximum availability of process equipment.

For more information contact Mark Bracco, Pepperl+Fuchs, +27 (0)87 985 0797, [email protected], www.pepperl-fuchs.co.za

| Tel: | +27 10 430 0250 |

| Email: | [email protected] |

| www: | www.pepperl-fuchs.com/en-za |

| Articles: | More information and articles about Pepperl+Fuchs |

© Technews Publishing (Pty) Ltd | All Rights Reserved